A vertical centrifugal pump is a vital piece of industrial equipment designed to transport liquids efficiently by converting rotational energy into kinetic energy through centrifugal force. Unlike horizontal pumps, a vertical pump centrifugal design features a vertically oriented shaft and motor, allowing the pump to operate with a smaller footprint while delivering stable and reliable performance. Thanks to these advantages, vertical centrifugal pumps have become an important alternative and complement to horizontal centrifugal pumps in water treatment, industrial processing, building services, and energy-related applications.

The working principle of a vertical centrifugal pump is based on centrifugal force. The pump consists mainly of a motor, a vertical shaft, an impeller, and a casing. When the motor starts, it drives the impeller to rotate at a set speed. Liquid enters the pump through the suction inlet and is thrown outward by the rotating impeller. This action increases the fluid’s velocity and pressure, allowing it to be discharged vertically or through an inline outlet, depending on the pump design.

In many designs, the motor is directly coupled to the pump shaft, reducing transmission losses and improving efficiency. This simple and compact structure ensures stable operation, high reliability, and consistent hydraulic performance across a wide operating range.

One of the most significant advantages of vertical centrifugal pumps is their compact installation. Because the shaft and motor are arranged vertically, these pumps occupy far less floor space than horizontal pumps. This makes them ideal for installations where space is limited, such as pump rooms in high-rise buildings or crowded industrial plants.

Other notable advantages include:

(1)Stable continuous operation: Vertical centrifugal pumps are well suited for 24/7 duty cycles and continuous processes.

(2)High-temperature and high-pressure capability: Their robust construction allows them to handle demanding operating conditions.

(3)Low vibration and smooth performance: Optimized hydraulic design ensures efficient energy use and reduced mechanical stress.

(4)Easy maintenance: Many vertical designs allow servicing without disturbing the piping system, saving time and cost.

(5)Wide media adaptability: Some models can handle slightly dirty liquids or media containing small solid particles.

Modern vertical pump centrifugal products benefit from continuous technological innovation. Advanced hydraulic simulation improves efficiency and smooths performance curves. Variable Frequency Drives (VFDs) are often used to adjust motor speed according to system demand, significantly reducing energy consumption.

In addition, high-quality materials such as stainless steel components, wear-resistant impellers, and advanced mechanical seals enhance durability and corrosion resistance. These design improvements reduce failure rates and ensure long-term, reliable operation even in harsh environments.

There are several common types of vertical centrifugal pumps, each designed for specific applications:

(1)Vertical Inline Centrifugal Pump:

A vertical inline centrifugal pump features suction and discharge ports on the same centerline, allowing direct installation into pipelines. This design is widely used for HVAC systems, building pressure boosting, and circulating water applications.

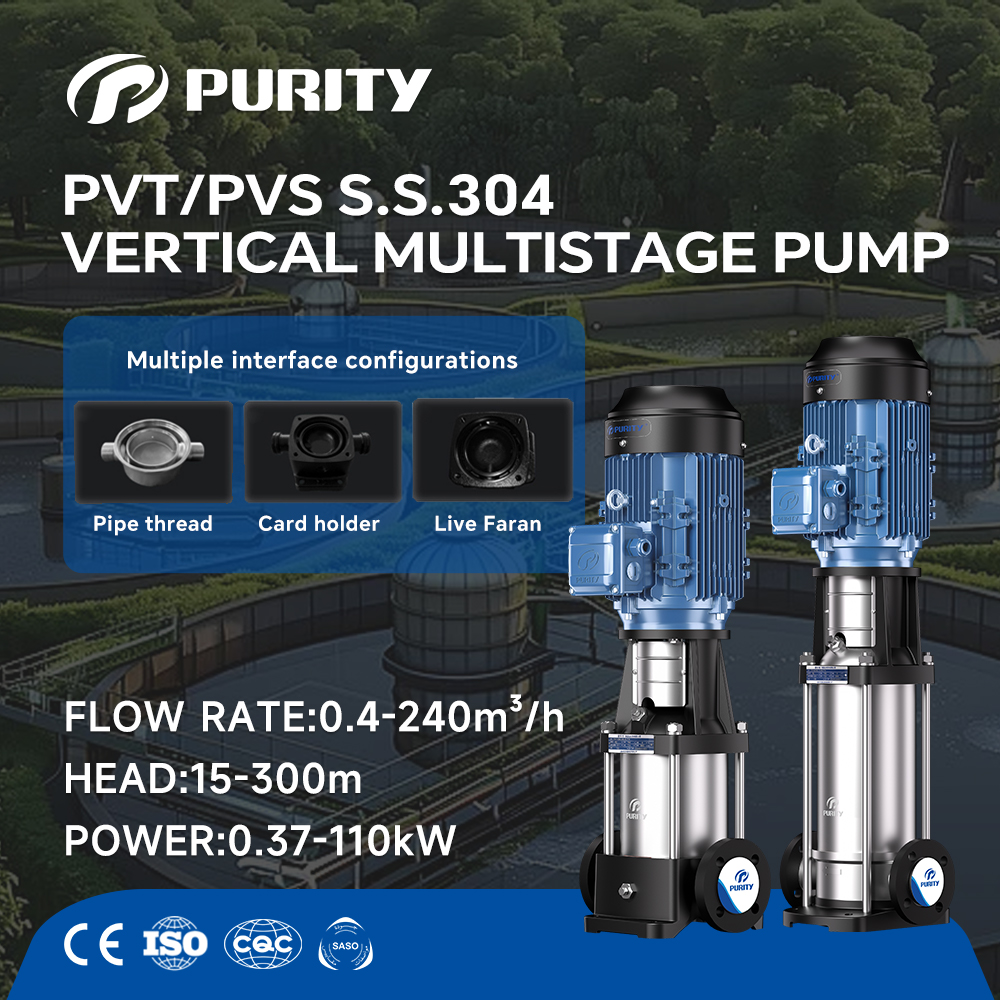

(2)Vertical Multistage Centrifugal Pump:

These pumps use multiple impellers arranged in series to achieve high pressure. They are commonly used as vertical centrifugal water pumps in water supply systems, high-rise building boosting, boiler feed water, and industrial pressure applications.

(3)General Vertical Centrifugal Water Pump:

Designed for clean or slightly corrosive liquids, these pumps are widely used in municipal water supply, irrigation, and water treatment facilities.

Due to their versatility, vertical centrifugal pumps are used across numerous industries, including:

(1)Municipal and building water supply and pressure boosting

(2)Industrial process systems and cooling water circulation

(3)Water treatment, desalination, and reverse osmosis systems

(4)Energy, power plants, and boiler feed applications

(5)Firefighting systems and agricultural irrigation

Their ability to operate reliably under continuous duty makes them a preferred choice for critical systems.

While pump design is crucial, the manufacturer’s capabilities play an equally important role. A professional pump manufacturer with strong research and development, in-house testing facilities, and a complete service system ensures consistent quality, reliable performance, and timely delivery.

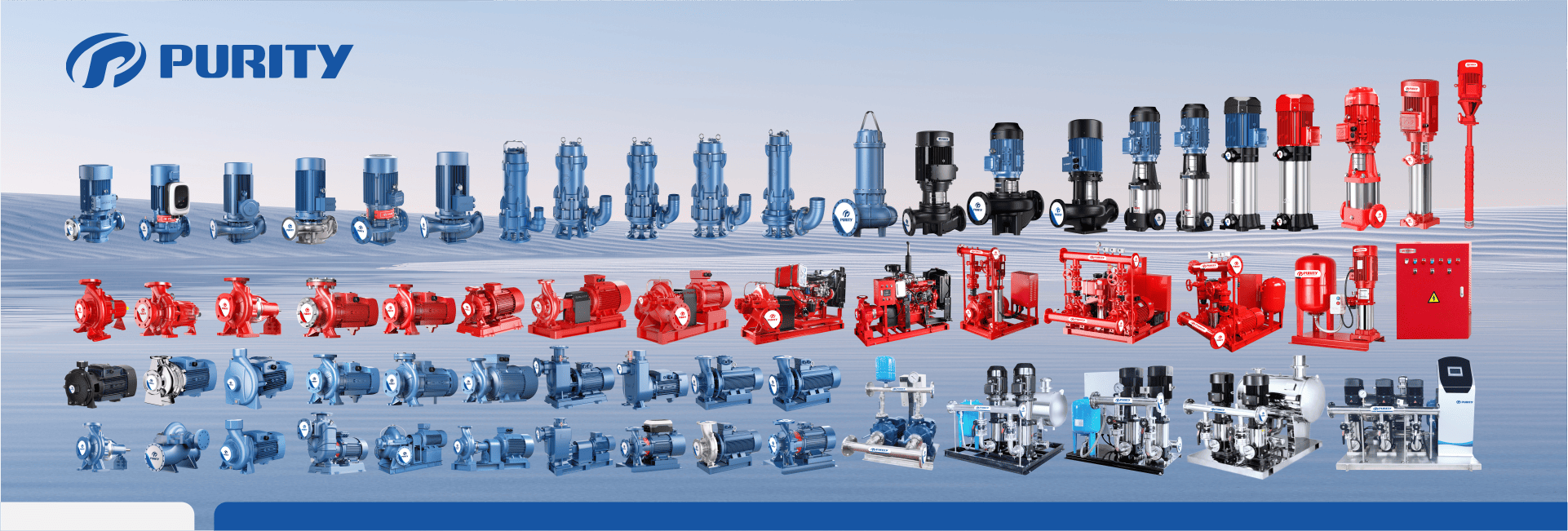

As a professional industrial pump manufacturer, Purity offers clear advantages in the field of vertical pumps:

1. Comprehensive product range: Purity provides various vertical pump types, including vertical multistage pumps, vertical inline centrifugal pumps, and other vertical centrifugal pump solutions.

2. International certifications: Multiple Purity vertical pump models have obtained CE certification, meeting global market requirements.

3. Complete model selection: With a full range of sizes and performance parameters, Purity vertical centrifugal water pumps can meet diverse customer needs.

4. Proven experience: With over 15 years of manufacturing and sales experience, Purity products have been exported to more than 130 countries and are produced in a 60,000 m² independent factory.