When choosing a centrifugal pump for water transfer or industrial applications, many users focus first on flow rate, head, or motor power. However, extensive engineering practice shows that pump material selection plays a decisive role in system reliability, service life, maintenance frequency, and total cost of ownership (TCO). This leads to a common and practical question: Which is better, a cast iron or a stainless steel centrifugal pump?

The short answer is: neither is universally better. There is no “best” material—only the most suitable material for a specific operating condition. Understanding the strengths and limitations of cast iron and stainless steel centrifugal pumps is essential for making the right decision.

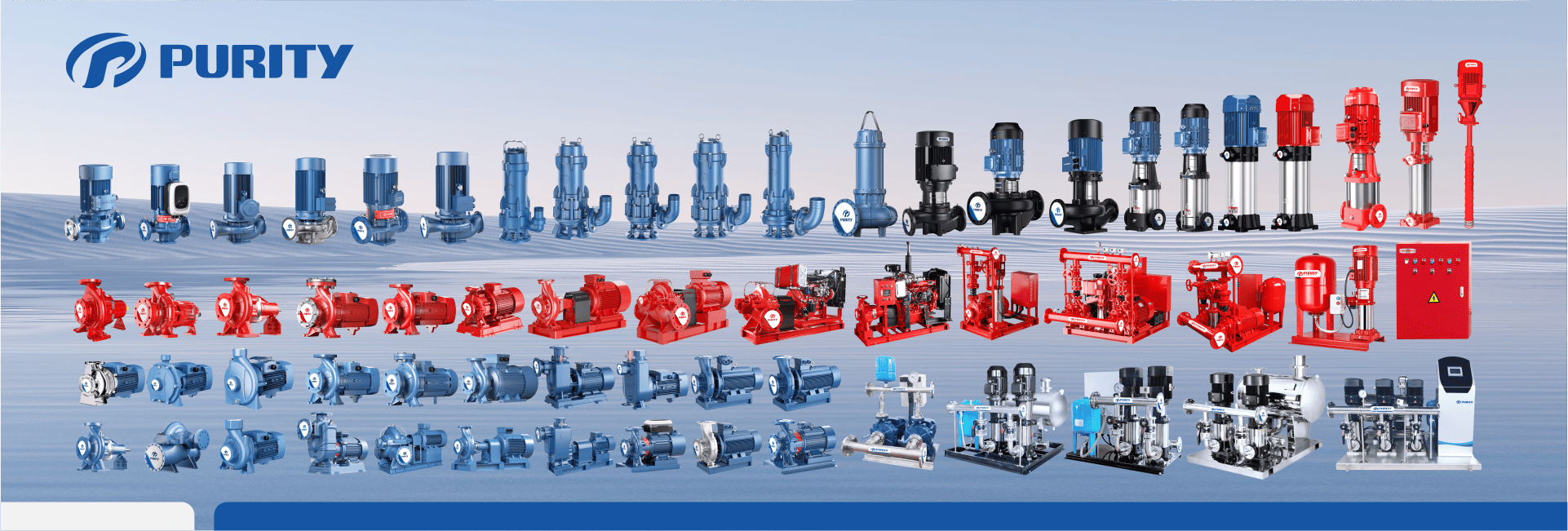

Picture | Purity Family Portrait

A centrifugal water pump may operate continuously in clean water systems, intermittently in drainage applications, or under harsh conditions involving corrosion, temperature fluctuations, or chemical exposure. If the pump material does not match the actual working environment, problems such as corrosion, efficiency loss, vibration, or premature failure can occur.

Experienced centrifugal pump manufacturers agree that correct material selection directly affects:

(1)Long-term reliability and operational stability

(2)Pump lifespan and maintenance cycles

(3)Energy efficiency over time

(4)Overall lifecycle cost rather than just initial price

Therefore, professional pump selection should always consider fluid characteristics and operating conditions, not only hydraulic performance.

A cast iron centrifugal water pump is one of the most widely used pump types worldwide. Cast iron has long been valued for its balance of affordability, strength, and stable operation.

Advantages of Cast Iron Centrifugal Pumps

(1)Cost-effective solution: Lower manufacturing and material costs make cast iron pumps ideal for budget-sensitive projects.

(2)High structural strength: Cast iron withstands pressure fluctuations and mechanical stress during long-term operation.

(3)Excellent vibration damping: The dense material naturally absorbs vibration, resulting in smooth and relatively quiet operation.

(4)Easy maintenance and repair: Spare parts are widely available, and cast iron components are easy to machine or replace.

Because of these advantages, cast iron pumps are commonly used in clean water supply, HVAC circulation systems, firefighting pumps, agricultural irrigation, and general industrial water transfer.

Limitations of Cast Iron Pumps

Despite their practicality, cast iron centrifugal pumps have clear limitations:

(1)Poor corrosion resistance in acidic, saline, or chemically aggressive fluids

(2)Not suitable for hygienic applications, such as potable water, food, or pharmaceutical systems

(3)Susceptible to rust in high-humidity or oxygen-rich environments

As a result, cast iron pumps perform best in non-corrosive, low-abrasion applications where operating conditions are well controlled.

When corrosion resistance or cleanliness becomes critical, a stainless steel centrifugal pump is often the preferred choice. Stainless steel grades such as 304 or 316 are widely used in demanding environments.

Advantages of Stainless Steel Centrifugal Pumps

(1)Excellent resistance to corrosion and oxidation, even in seawater or chemically aggressive fluids

(2)Smooth, non-porous surfaces that reduce contamination and bacterial growth

(3)High chemical compatibility, suitable for a wide range of liquids

(4)Lower maintenance requirements and longer service life in corrosive environments

Thanks to these properties, stainless steel pumps are widely applied in chemical processing, food and beverage production, pharmaceutical systems, seawater handling, and corrosive wastewater treatment.

(1)Higher upfront investment compared with cast iron pumps

(2)Lower abrasion resistance than specialized materials such as high chrome alloys

(3)Not ideal for heavy slurry applications with sharp solids

However, in corrosion-dominated conditions, stainless steel pumps often deliver better long-term value despite the higher initial cost.

|

Criteria |

Cast Iron Centrifugal Pump |

Stainless Steel Centrifugal Pump |

|

Initial Cost |

Low |

Medium to High |

|

Corrosion Resistance |

Low |

Excellent |

|

Hygiene & Cleanliness |

Poor |

Excellent |

|

Operational Stability |

Very Good |

Good |

|

Maintenance Frequency |

Moderate |

Low |

|

Typical Applications |

Clean water, HVAC, fire systems |

Chemicals, potable water, seawater |

This comparison highlights an important principle: material selection should match the operating environment, not just the purchase price.

With over 15 years of experience as a centrifugal pump manufacturer, Purity provides both cast iron and stainless steel centrifugal pump solutions to meet diverse industry needs.

(1)Purity PZ Stainless Steel Centrifugal Pump

Designed with a suction inlet diameter larger than the discharge outlet, this structure reduces vortex formation and lowers NPSH requirements. The result is stable operation, reduced cavitation risk, and low noise levels. All wetted parts are made of stainless steel for clean and environmentally friendly performance, and the pump is equipped with a high-efficiency energy-saving motor.

Picture | Purity Stainless Steel Centrifugal Pump PZ

(2)Purity PSM Cast Iron Centrifugal Water Pump

Featuring hydraulic simulation design, the PSM series delivers smooth performance curves and high efficiency. It is fitted with a standard high-efficiency motor and is available in a wide range of models, sizes, and power ratings, making it suitable for various clean-water applications.

Picture | Purity Cast Iron End Suction Pump PSM

So, which is better, a cast iron or a stainless steel centrifugal pump?

The correct choice depends entirely on your application:

(1)Choose a cast iron centrifugal water pump for clean, non-corrosive fluids where cost efficiency, strength, and stable operation are the priorities.

(2)Choose a stainless steel centrifugal pump when corrosion resistance, hygiene, and long-term reliability are critical.

Both materials play an essential role in modern pump systems. By selecting the right pump based on fluid properties (corrosion, abrasiveness, pH), operating conditions, and lifecycle cost, users can significantly extend pump life, reduce downtime, and optimize overall operating expenses.

Purity, as a professional centrifugal pump manufacturer, offers a wide range of certified products, including stainless steel and cast iron centrifugal pumps, compliant with CE, SASO, and ISO standards. We are actively seeking global partners—contact us today to find the ideal pump solution for your application.