Self-priming is a critical concept in modern pump engineering, especially for applications where liquid supply conditions are unstable or where frequent start–stop operation is required. A self-priming centrifugal pump is specifically designed to remove air from the pump casing and suction pipeline automatically during startup, allowing the pump to begin transferring liquid without manual priming. This capability makes self-priming pumps far more practical and reliable than conventional centrifugal pumps in complex operating environments.

In a standard centrifugal pump, the casing and suction line must be completely filled with liquid before startup. If air remains inside, the pump cannot generate sufficient negative pressure to draw fluid, leading to dry running or failure. A self-priming centrifugal pump overcomes this limitation through a specially engineered internal structure.

By retaining a certain amount of liquid inside the pump casing after shutdown, and by using gas–liquid separation chambers, return passages, or priming cavities, the pump can continuously expel air during startup. As air is discharged, a stable vacuum forms at the suction inlet, enabling liquid to be lifted and transported efficiently. Once self-priming is complete, the pump transitions seamlessly into the same high-efficiency continuous operation as a normal centrifugal pump.

Whether the design is centrifugal or positive displacement, the fundamental self-priming mechanism is similar. Residual liquid inside the pump mixes with incoming air, forming a gas–liquid mixture that is circulated through internal channels. The air is separated and discharged, while the liquid is recirculated back into the impeller zone.

This shared principle explains why self-priming centrifugal pumps can achieve reliable startup even under suction lift conditions, intermittent operation, or pipelines prone to air ingress. Once primed, performance characteristics such as flow rate and efficiency match those of conventional centrifugal pumps.

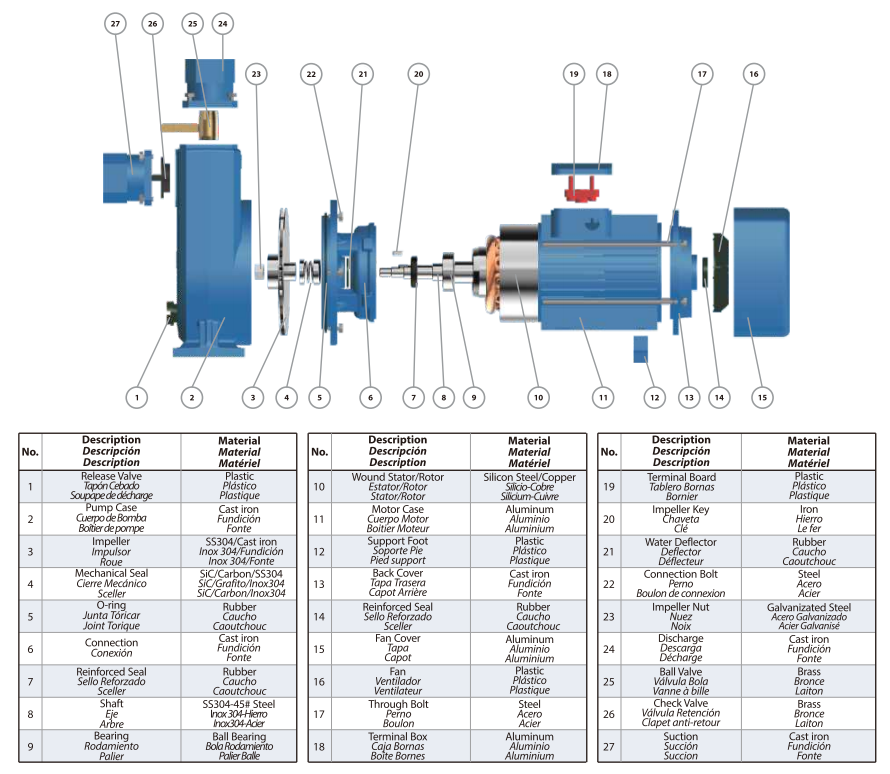

The superior performance of a self-priming centrifugal pump is largely determined by its internal structure. Key design features typically include:

(1) Strong air-handling capability to manage gas-liquid mixtures

(2) Check valves or flap valves to prevent backflow after shutdown

(3) Large water chambers to store residual liquid

(4) Internal circulation or reflux systems to accelerate air evacuation

These features allow the pump to restart quickly, even when the suction line is empty or partially filled with air. As a result, horizontal self-priming centrifugal pumps are particularly popular in installations where pumps are located above the liquid level.

Self-priming pumps are available in a wide range of configurations, covering clean water, wastewater, slurry, high-viscosity fluids, and media containing solids. Variants such as self-priming sewage pumps are designed with wide impeller flow passages and anti-clog structures, making them suitable for harsh working conditions.

This diversity enables self-priming centrifugal pump manufacturers to serve industries with vastly different requirements, from municipal infrastructure to industrial processing.

Compared with ordinary pump types, self-priming centrifugal pumps offer several clear advantages:

(1) No need for manual priming, reducing labor and downtime

(2) High adaptability to air-entrained or unstable liquid sources

(3) Lower maintenance requirements due to simplified operation

(4) Flexible installation and suitability for frequent start–stop cycles

These benefits make self-priming pumps especially valuable in demanding environments where reliability and safety are critical.

Self-priming centrifugal pumps are widely used in:

(1) Municipal sewage and wastewater drainage systems

(2) Construction site and foundation pit dewatering

(3) Agricultural irrigation and water transfer

(4) Firefighting and emergency pumping systems

In these scenarios, the ability to start quickly and handle air, solids, or fluctuating water levels is essential.

Among many solutions on the market, the Purity PXZ self-priming centrifugal pump stands out for its robust design and reliability. The pump shaft is manufactured using welded 304 stainless steel, significantly enhancing corrosion resistance and extending service life. Its pump body and impeller feature wide flow passages, delivering strong solids-handling capability and reducing clogging risks.

In addition, the PXZ series adopts an extra-large water chamber combined with a uniquely designed reflux hole, which greatly improves self-priming performance and shortens priming time. These structural advantages allow the pump to perform consistently in sewage, drainage, and other air-prone applications.

When evaluating self-priming centrifugal pump price, it is important to consider not only the initial cost but also long-term reliability, maintenance needs, and operating efficiency. Established self-priming centrifugal pump manufacturers typically provide better quality control, standardized testing, and technical support, resulting in lower total lifecycle costs.

Self-priming technology represents a major advancement in centrifugal pump design. By combining high reliability, strong adaptability, and ease of operation, the self-priming centrifugal pump significantly improves efficiency and safety in modern fluid handling systems. It is an ideal solution for applications involving air, solids, or the need for rapid and frequent startup.

With 15 years of focus on industrial self-priming pumps, Purity operates a 16,000 m² independent factory and supplies products to more than 130 countries worldwide. Committed to quality and long-term partnerships, Purity aims to be your preferred pump supplier and is actively seeking global agents—contact us today to explore cooperation opportunities.