When it comes to fluid transportation, selecting the right type of pump is crucial for ensuring optimal performance, efficiency, and cost-effectiveness. Two common types of pumps used across industries are centrifugal water pumps and multistage centrifugal pumps. In this article, we will explore the differences, advantages, and applications of these pumps, with a focus on vertical multistage pumps and their specific benefits.

Figure | Purity Centrifugal Pump Family Portrait

A centrifugal water pump is one of the most widely used types of pumps for transferring liquids. It operates using an impeller to create centrifugal force, which propels water through the pump and out of the discharge point.

· Key Features:

o Simple structure and easy maintenance.

o Suitable for low to medium head (up to 125 meters).

o Efficient for clean water and liquids with low solid content.

· Common Applications:

o HVAC systems

o Water circulation

o General liquid transfer tasks

Single-stage centrifugal water pumps are ideal when the required head is below 125 meters, and the system demands reliability with minimal maintenance.

A multistage centrifugal pump consists of two or more impellers arranged in series. Each impeller increases the pressure of the liquid as it passes through, allowing the pump to achieve significantly higher heads.

· Key Features:

o Suitable for high-pressure applications (head above 125 meters).

o Higher efficiency due to smaller impeller diameters and tighter clearances.

o Typically requires less motor horsepower for the same output.

· Common Applications:

o High-rise building water supply

o Boiler feedwater systems

o Industrial high-pressure systems

Multistage pumps, especially vertical multistage centrifugal pumps, are preferred in scenarios where space is limited, as they are often designed with a vertical configuration to save floor space.

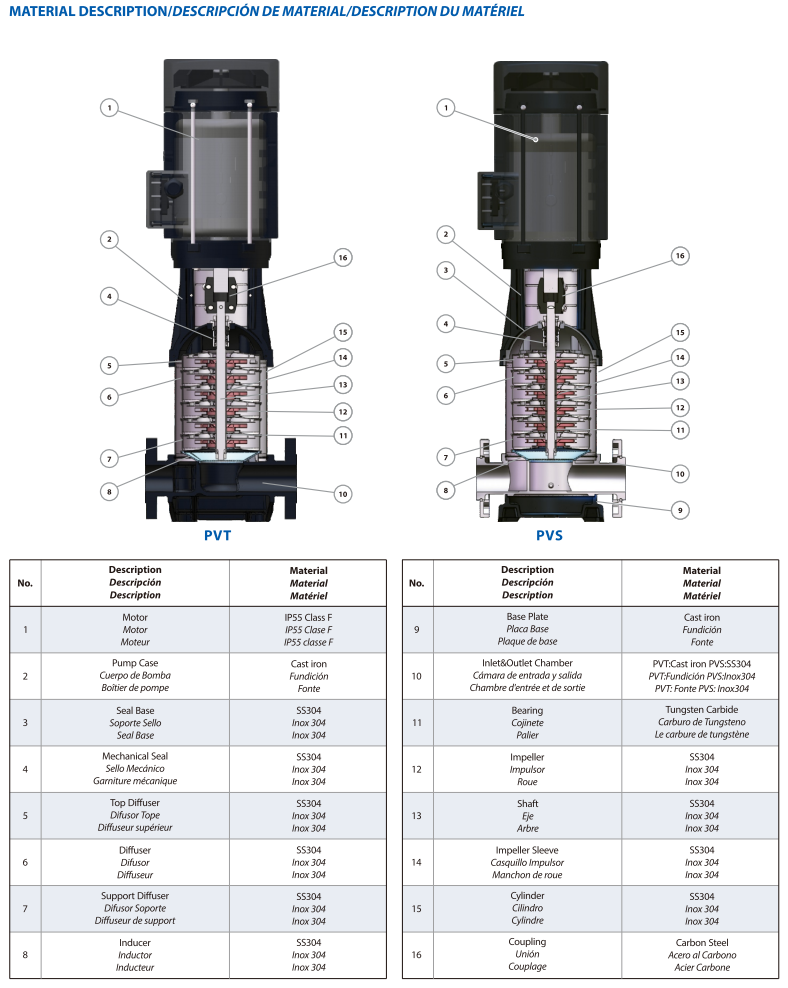

Figure | Purity vertical multistage pump PVT parts

· Centrifugal Water Pump: Effective for low to medium pressure needs (below 125 meters).

· Multistage Pump: Ideal for applications requiring high head and pressure (above 125 meters).

· Centrifugal Pump: Generally efficient at low head and large flow applications.

· Multistage Pump: Offers higher efficiency in high-pressure applications due to optimized impeller design.

· Centrifugal Pump: Flow can be controlled manually using valves.

· Multistage Pump: Requires a Variable Frequency Drive (VFD) for pressure control and flexibility.

· Centrifugal Pump: Better suited for liquids containing solids or debris.

· Multistage Pump: Designed for clean liquids; not suitable for solid-containing fluids.

· Centrifugal Pump: May require more space if multiple pumps are installed in series.

· Vertical Multistage Pump: Space-efficient, particularly when installed vertically.

· Centrifugal Pump: Easier to maintain due to fewer components.

· Multistage Pump: More complex maintenance with higher installation requirements.

Vertical multistage centrifugal pumps offer a unique combination of compact design, efficiency, and high performance.

· Space-Saving Design: The vertical alignment minimizes the pump's footprint.

· High Efficiency: Smaller impeller diameters and precision engineering improve energy efficiency.

· Easy Installation: Designed for easier integration into pipeline systems.

· Durability: Equipped with mechanical seals for better wear resistance and reduced leakage.

One standout example is the Purity PVT Vertical Multistage Pump, which boasts superior performance compared to competitors:

· Stainless steel casing for durability.

· Advanced mechanical seals for longer service life.

· Compact design for minimal space requirements.

Figure | Purity vertical multistage pump PVT real shot

When deciding between a centrifugal water pump and a multistage centrifugal pump, consider the following factors:

· Required Head: Below 125 meters → Centrifugal pump; Above 125 meters → Multistage pump.

· Fluid Characteristics: Clean liquids → Multistage; Liquids with solids → Centrifugal.

· Space Constraints: Tight spaces → Vertical multistage pump.

· Operational Flexibility: For variable pressure requirements, multistage pumps with VFD are more suitable.

For many industrial and municipal applications, vertical multistage centrifugal pumps strike the perfect balance between performance, efficiency, and space-saving design.

Both centrifugal water pumps and multistage pumps have their strengths and are tailored for specific operational needs. While centrifugal pumps excel in simple, low-head applications, multistage pumps, particularly vertical multistage centrifugal pumps, are unbeatable in high-pressure systems requiring reliability and energy efficiency.Purity vertical multistage pumps are designed for optimal performance, durability, and energy savings.Have questions about your pumping system requirements? Contact us today for expert advice and customized solutions!