Centrifugal pumps are one of the most widely used pump types across various industries, offering reliable solutions for fluid transport. They convert mechanical energy into kinetic and pressure energy, making them ideal for a range of applications. This article will explore the working principles of centrifugal pumps, their classifications, and the factors to consider when selecting the right pump for your needs.

Figure | Purity centrifugal pump full range

Centrifugal pumps function based on the simple yet effective principle of converting rotational energy into fluid movement. The pump contains an impeller, which is powered by a motor to rotate at high speeds. As the impeller spins, it imparts kinetic energy to the fluid, increasing its velocity. The fluid is then directed through the pump casing, where the velocity energy is converted into pressure energy, forcing the fluid to flow through the discharge pipe. This design enables the centrifugal pump to handle various fluid types and conditions efficiently.

There are several types of centrifugal pumps, each suited to specific applications based on factors like flow rate, pressure, and fluid characteristics. The three main categories are:

Radial flow centrifugal pumps are the most commonly used type. In these pumps, the fluid flows radially from the center to the outer edges of the impeller. This design makes them ideal for applications that require high pressure but relatively low flow rates. Radial flow pumps are frequently used in water supply systems, HVAC (heating, ventilation, and air conditioning) applications, and chemical processing.

Applications:

· Centrifugal pump water systems, where high pressure is needed.

· HVAC systems for cooling and heating.

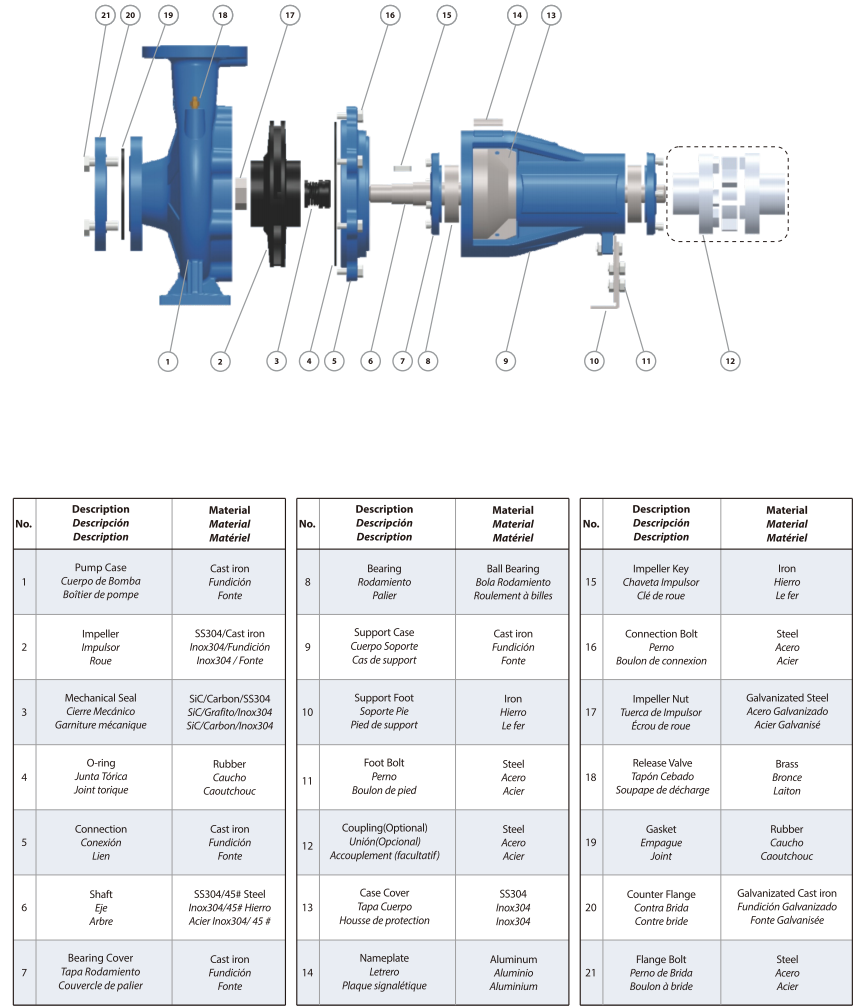

Figure | Purity radial centrifugal pump parts

Axial flow pumps operate by moving the fluid parallel to the pump shaft. The impeller in axial flow pumps generates an axial force, causing the fluid to flow along the axis of the pump. These pumps are particularly effective in applications where a large volume of fluid is needed at relatively low pressures. For example, in agricultural irrigation or large-scale cooling systems, axial flow pumps can handle high flow rates with lower pressure requirements.

Applications:

· Agricultural irrigation systems.

· Cooling water systems in power plants and industrial processes.

Mixed flow pumps combine elements of both radial and axial flow designs. Fluid enters at an angle to the impeller, resulting in a mixture of radial and axial flow. This design allows mixed flow pumps to offer a balance between flow rate and pressure, making them versatile for medium-pressure applications.

Applications:

· Water supply and irrigation systems that require medium-pressure operation.

· Cooling systems in various industrial processes.

The design of the impeller plays a critical role in the efficiency and performance of centrifugal pumps. Impellers come in different configurations, each suited to specific fluid types and operational needs.

· Open impellers: These are used for handling fluids with a high solid content or high viscosity, such as wastewater treatment and slurry transport.

· Semi-open impellers: Ideal for fluids with medium solid content or moderate viscosity.

· Closed impellers: These are the most efficient and are commonly used for clean water and industrial applications that require high-efficiency pumping.

Vertical centrifugal pumps, as the name suggests, are designed with a vertical shaft. The fluid is moved vertically by the impeller, making these pumps ideal for applications where space is limited, or where the pump needs to be positioned deep in a well or tank. Vertical pumps are often used in wastewater treatment plants and water sumps.

Applications:

· Wastewater treatment.

· Water sump systems.

Vertical multistage centrifugal pumps consist of multiple impellers arranged in series, which allows the pump to generate higher pressures. These pumps are ideal for applications that require higher pressure capabilities, such as boiler feedwater systems and seawater desalination plants. The multiple stages ensure that the fluid is pressurized efficiently at each stage, making multistage pumps highly effective in demanding environments.

Applications:

· Boiler feedwater systems.

· Seawater desalination plants.

· High-pressure water supply.

Figure | Purity new vertical multistage pump PVE

When selecting a centrifugal pump, it is crucial to consider the following factors:

· Flow rate: The volume of fluid that the pump can handle over a given time period.

· Head (pressure): The amount of pressure the pump can generate to move fluid through the system.

· Viscosity of the fluid: Higher viscosity fluids require pumps with more power and specific impeller designs.

· Pump material: The material of the pump casing and impeller should be compatible with the fluid being pumped, especially for corrosive or abrasive fluids.

· Application needs: The specific requirements of your industry, such as water supply, HVAC systems, or chemical processing, will determine the best type of pump to use.

Centrifugal pumps, whether radial flow, axial flow, or mixed flow, offer a wide range of solutions for fluid transport across industries. The right choice of pump depends on your specific requirements for flow rate, pressure, and fluid characteristics. Vertical centrifugal pumps and vertical multistage centrifugal pumps provide space-saving and high-pressure options for specialized applications. When selecting a pump, consider factors like fluid type, system requirements, and maintenance needs to ensure optimal performance.

At Purity Pump, we offer a diverse range of centrifugal pumps, including vertical multistage pumps and stainless steel centrifugal pumps, designed to meet the demands of various industries. With CE and EU certifications, we are committed to providing reliable and efficient pumping solutions for all your needs. If you are looking for the right centrifugal pump, don't hesitate to reach out for a consultation.