A centrifugal pump is a mechanical device designed to transport liquids by converting rotational energy from an impeller into kinetic and pressure energy. Known for their efficiency and reliability, these pumps are widely used in water supply, chemical processing, and wastewater treatment, playing an indispensable role in both industrial and commercial applications.

Figure | Purity centrifugal pump family portrait

The working mechanism of a centrifugal pump is based on the principle of centrifugal force, ensuring a continuous and stable flow of liquids:

1. Fluid Entry: Liquid enters the pump through the suction pipe and flows into the center (eye) of the impeller.

2. Energy Conversion: As the impeller rotates, centrifugal force propels the liquid outward, increasing its velocity and kinetic energy.

3. Pressure Increase: The high-speed liquid moves along the impeller blades into the pump casing (volute or diffuser), where kinetic energy is converted into pressure energy.

4. Fluid Discharge: The pressurized liquid exits the pump through the discharge pipe.

This efficient process makes centrifugal pumps ideal for a wide range of applications requiring stable fluid flow.

A centrifugal pump comprises several essential components, each playing a critical role in its operation:

· Impeller: The rotating component responsible for transferring energy to the fluid. Impellers come in different designs—open, semi-open, and closed—to handle various fluid types and conditions.

· Pump Shaft: Connects the motor to the impeller, driving its rotation.

· Pump Casing: Encloses the impeller, directs fluid flow, and protects internal components.

· Suction and Discharge Pipes: Facilitate the fluid's entry and exit from the pump.

· Mechanical Seals or Packing: Prevent leakage from the pump casing.

The quality and design of these components directly impact the efficiency and durability of the pump.

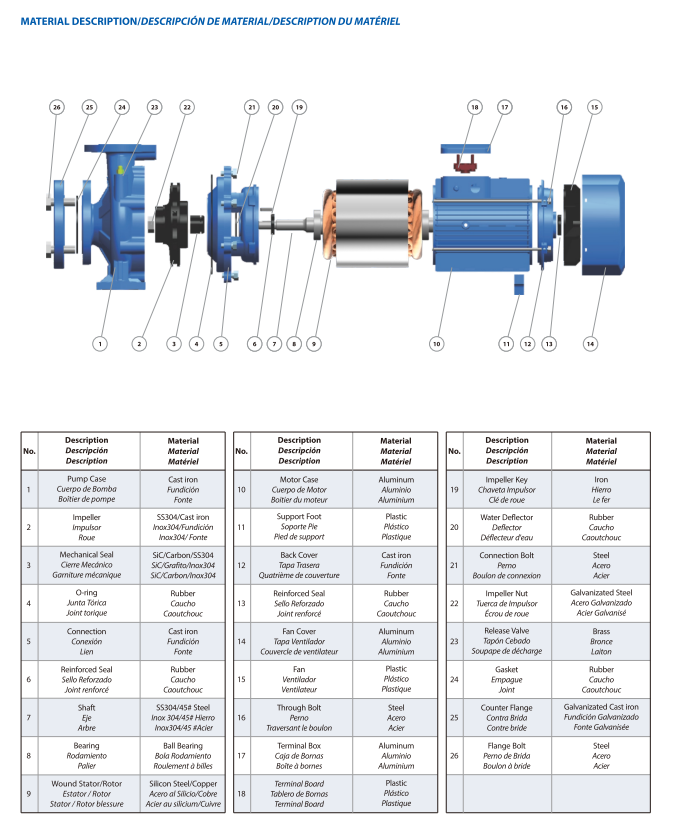

Figure | PST centrifugal pump parts

Different applications require specific types of centrifugal pumps:

1. Single-Suction Pump: Draws liquid from one side of the impeller, ideal for low-flow applications.

2. Double-Suction Pump: Equipped with dual inlet impellers, suitable for high-flow operations.

3. Trash Pump: Designed to handle liquids containing solid particles, commonly used in construction and wastewater management.

4. Chemical Pump: Made from corrosion-resistant materials, perfect for transporting aggressive chemicals.

5. Multistage Pump: Contains multiple impellers for high-pressure applications, such as boiler feedwater or high-rise building water supply.

Each type serves a unique purpose, ensuring optimal performance across various industries.

Due to their versatility and efficiency, centrifugal pumps are widely used in numerous sectors:

· Water Treatment: Municipal and industrial water supply systems.

· Oil and Gas: Transportation of petroleum products in refineries.

· Food and Beverage: Handling fluids like milk, juice, and syrup.

· Fire Protection: Supplying water for firefighting sprinkler systems.

These diverse applications highlight the pump’s adaptability in different environments.

Centrifugal pumps are highly favored for their significant benefits:

· Simple Design: Easy installation and maintenance.

· Steady Flow: Provides continuous and consistent fluid delivery.

· Energy Efficient: Optimized design ensures efficient energy consumption.

· Low Maintenance Costs: Minimal upkeep compared to other pump types.

Figure | PST centrifugal water pump

Purity PST centrifugal pumps stand out in the competitive market with their advanced features:

1. Comprehensive Product Range: A wide selection of models, sizes, and power options to meet diverse customer needs.

2. IP55 Protection and F-Class Insulation: Ensures durability and resistance to challenging operating conditions.

3. Smooth Performance Curves: Wide flow range and performance characteristics comparable to international competitors.

These advantages make Purity centrifugal pumps a reliable choice for various industrial and commercial operations.

Centrifugal pumps, including centrifugal water pumps, chemical pumps, and trash pumps, are essential tools for fluid handling across industries. Understanding the working mechanism of a centrifugal pump, selecting the right types of centrifugal pumps, and ensuring the quality of centrifugal pump impellers are crucial for achieving optimal performance.

Purity centrifugal pumps offer an unparalleled combination of efficiency, durability, and advanced technology, making them an ideal choice for modern pumping solutions. For reliable and efficient pumping systems, Purity centrifugal pumps are ready to meet your needs. If you are interested, don’t hesitate to contact us today!