A self-priming centrifugal pump is a specialized type of industrial centrifugal pump designed to automatically remove air or gas from the suction side, enabling fluid pumping without external priming assistance. This innovation addresses a critical limitation of traditional centrifugal pumps, which require a primed (fluid-filled) impeller and casing to function efficiently. Self-priming centrifugal pumps are especially suitable for applications where the pump is installed above the fluid source or where the pumped fluid contains air pockets.

Figure | Purity Self-priming Centrifugal Pump-PXZ

1. Air-Handling Capability: These pumps effectively handle gas-liquid mixtures, maintaining their primed state even under challenging conditions.

2. Integrated Mechanisms: Many models incorporate features like check valves or recirculation systems to ensure continuous operation and prevent backflow.

3. Versatile Application Range: Their adaptability to various fluids and environments makes them indispensable in industries such as agriculture, construction, and wastewater management.

The working principle of a self-priming centrifugal pump involves several key steps:

1. Initial Filling: Before operation, the pump casing is partially filled with liquid, which is essential for creating the initial seal.

2. Air Evacuation: As the pump starts, the impeller’s rotation generates centrifugal force, pushing the liquid outward while simultaneously driving air towards the discharge outlet. The expelled air escapes through a vent, creating a vacuum.

3. Fluid Suction: The vacuum draws fluid from the source into the pump casing, mixing with the residual liquid.

4. Continuous Operation: Once primed, the pump handles any incoming air or gas pockets, ensuring uninterrupted fluid transfer.

This seamless process eliminates the need for manual priming, making these pumps highly efficient and user-friendly.

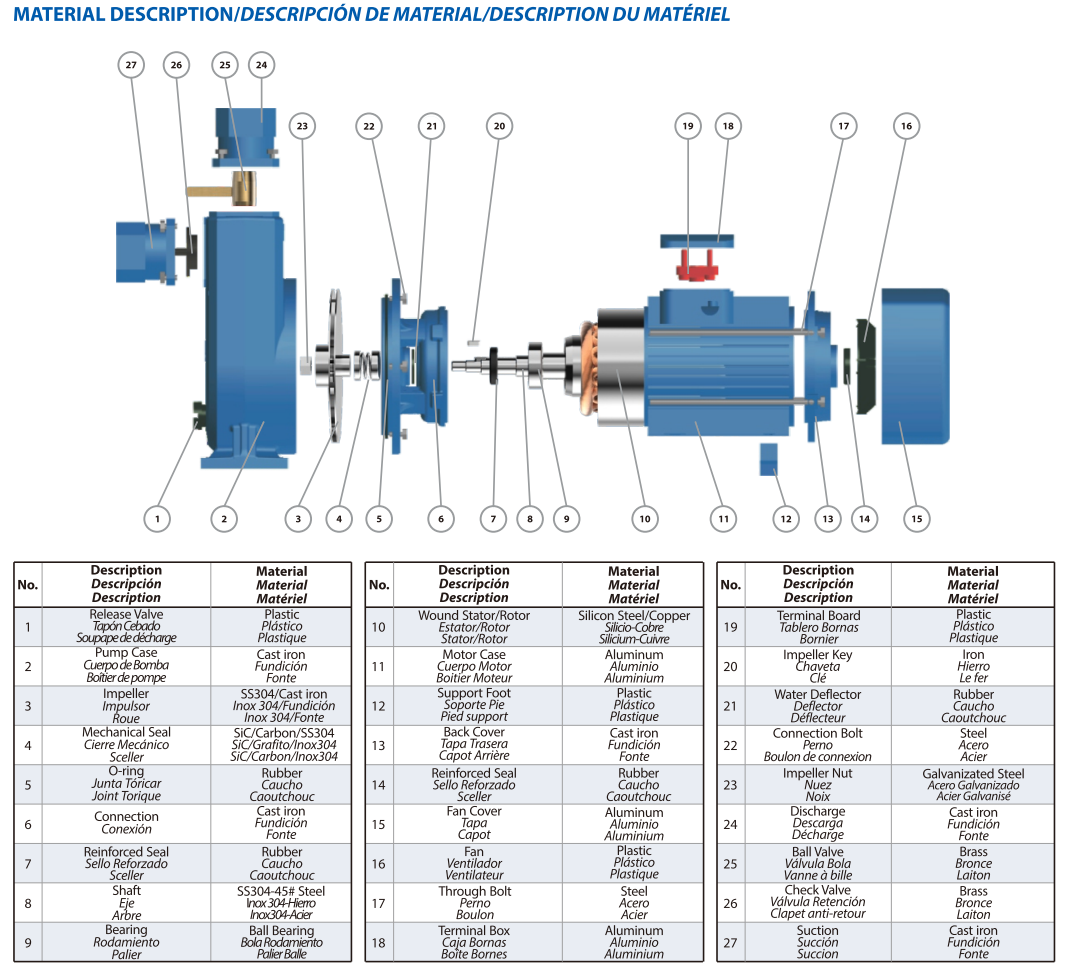

Figure | Purity Self-priming Centrifugal Pump PXZ Components

Self-priming centrifugal pumps are available in various configurations to suit different industrial and agricultural applications:

1. Standard Self-Priming Pumps: Ideal for transferring clean water or lightly contaminated liquids, often used as centrifugal irrigation pumps in agriculture.

2. Trash Pumps: Built to handle liquids containing solids or debris, these are widely used in construction and municipal wastewater management.

3. Jet-Assist Self-Priming Pumps: Utilize a venturi effect to enhance suction, commonly applied in shallow wells and domestic water systems.

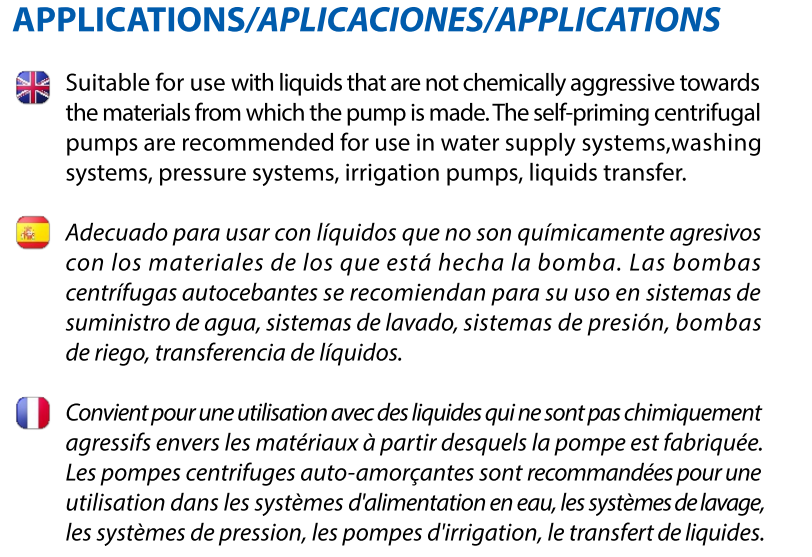

Self-priming centrifugal pumps have diverse applications across industries, including:

1. Wastewater and Sewage Management: Efficiently transfer sludge, sewage, and wastewater in municipal and industrial facilities.

2. Construction and Dewatering: Remove accumulated water from construction sites, basements, and excavation areas.

3. Irrigation Systems: Serve as centrifugal irrigation pumps to draw water from rivers, reservoirs, or wells for agricultural use.

4. Marine and Bilge Operations: Provide reliable bilge pumping solutions for ships and boats.

5. Emergency and Flood Control: Rapidly pump out water in flood-prone areas or during emergencies.

6. Industrial Fluid Handling: Transport chemicals, oils, and other liquids in manufacturing and processing industries.

Figure | Purity Self-priming Centrifugal Pump PXZ Applications

1. Ease of Use: The self-priming feature eliminates the need for external priming devices or manual intervention.

2. Versatility: Adaptable to a wide range of fluids, including those with solids or gas content.

3. Efficiency: High-performance models, like centrifugal irrigation pumps, ensure effective water delivery with minimal downtime.

4. Durability: Rugged designs withstand demanding environments and continuous operation.

Purity single stage self-priming centrifugal pumps exemplify advanced engineering with features that set them apart:

1. Energy-Efficient Motors: Equipped with internationally certified, pure copper-coil motors that ensure low temperature rise and high efficiency.

2. User-Friendly Installation: The water inlet and outlet are connected by threaded connections, which is convenient for users to install.

As industries demand more efficient and reliable fluid transfer solutions, self-priming centrifugal pumps are poised for significant advancements. Innovations in energy efficiency, smart monitoring systems, and materials technology will further enhance their performance and broaden their application scope.

In summary, self-priming centrifugal pumps are a cornerstone of modern fluid handling, offering unmatched convenience, efficiency, and versatility. Whether for industrial centrifugal pump applications or as centrifugal irrigation pumps, these pumps continue to set the standard for performance and reliability. Purity’s self-priming pumps, with their advanced features and superior build quality, are an excellent choice for those seeking dependable solutions. Contact us today to learn more!