Multistage centrifugal pumps are highly efficient and versatile centrifugal water pumps designed to meet the demanding requirements of highhead and highpressure applications. These industrial centrifugal pumps play a crucial role in various industries and have unique design features that set them apart. Let’s explore the key aspects of multistage centrifugal pumps, including their definition, structure, types, advantages, applications, and advancements, such as the new PVE vertical multistage centrifugal pump by Purity.

A multistage centrifugal pump consists of two or more impellers arranged in series, through which fluid is gradually pressurized stage by stage. Each stage includes components like impellers, diffusers, and return guide vanes, which work in unison to channel the fluid efficiently.

The pump’s internal balancing devices, such as balance discs or balance drums, minimize axial thrust to ensure smooth and stable operation. Regardless of the pump’s configuration — whether horizontal or vertical — its primary function is to incrementally increase pressure while maintaining a constant flow rate.

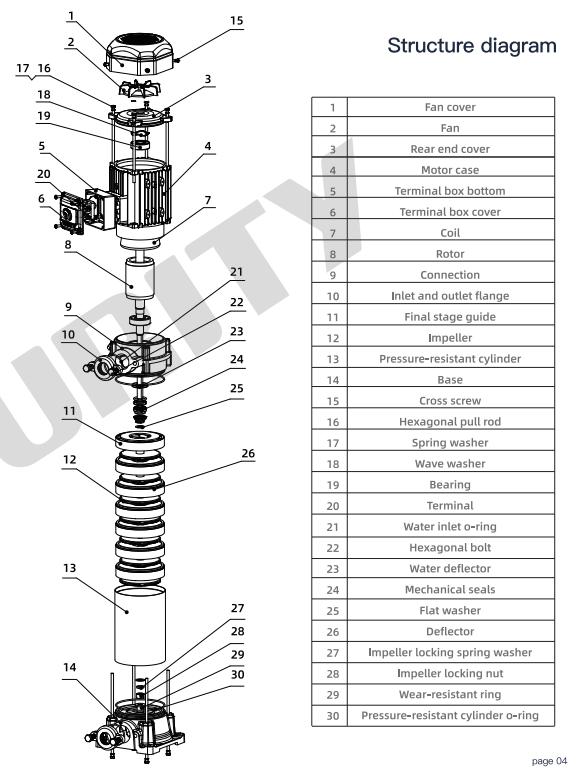

Multistage pumps feature several key components, including:

Impellers: Enhance fluid pressure and determine performance.

Diffusers: Guide fluid to the next impeller with minimal loss.

Balancing Devices: Reduce thrust for reliable operation in highhead conditions.

Common types of multistage centrifugal pumps include:

1. Horizontal Multistage Pumps: These are groundmounted and ideal for hightemperature and highpressure applications.

2. Vertical Multistage Centrifugal Pumps: Compact and spacesaving, these vertical centrifugal pumps are suited for installations in confined spaces or submerged environments.

3. Other Variants: Include side channel pumps, sanitary pumps, and vertical turbine pumps, each tailored for specific applications.

Figure | vertical multistage pump Structure diagram

Multistage centrifugal pumps offer several advantages:

1. HighEfficiency Pressure Boosting: The series arrangement of impellers enables significant pressure increases, surpassing the capabilities of singlestage pumps.

2. Flexible Design: Impellers can be tailored in size and number to meet diverse operational needs.

3. Energy Savings and Noise Reduction: Smaller impeller diameters reduce energy consumption and operational noise levels.

4. Adaptability: Interstage bleed options allow for performance adjustments, making these pumps suitable for various duty points.

The versatility of multistage centrifugal pumps makes them indispensable across industrial and residential settings. Key applications include:

HighRise Building Water Supply: Ensuring sufficient pressure for overhead tank systems.

Boiler Feed Water: Supporting power plant operations.

Reverse Osmosis (RO) Systems: Facilitating water purification processes.

Oil and Gas Production: Handling fluids in highpressure environments.

Other Uses: Highpressure cleaning, firefighting, irrigation, and snowmaking for sports resorts.

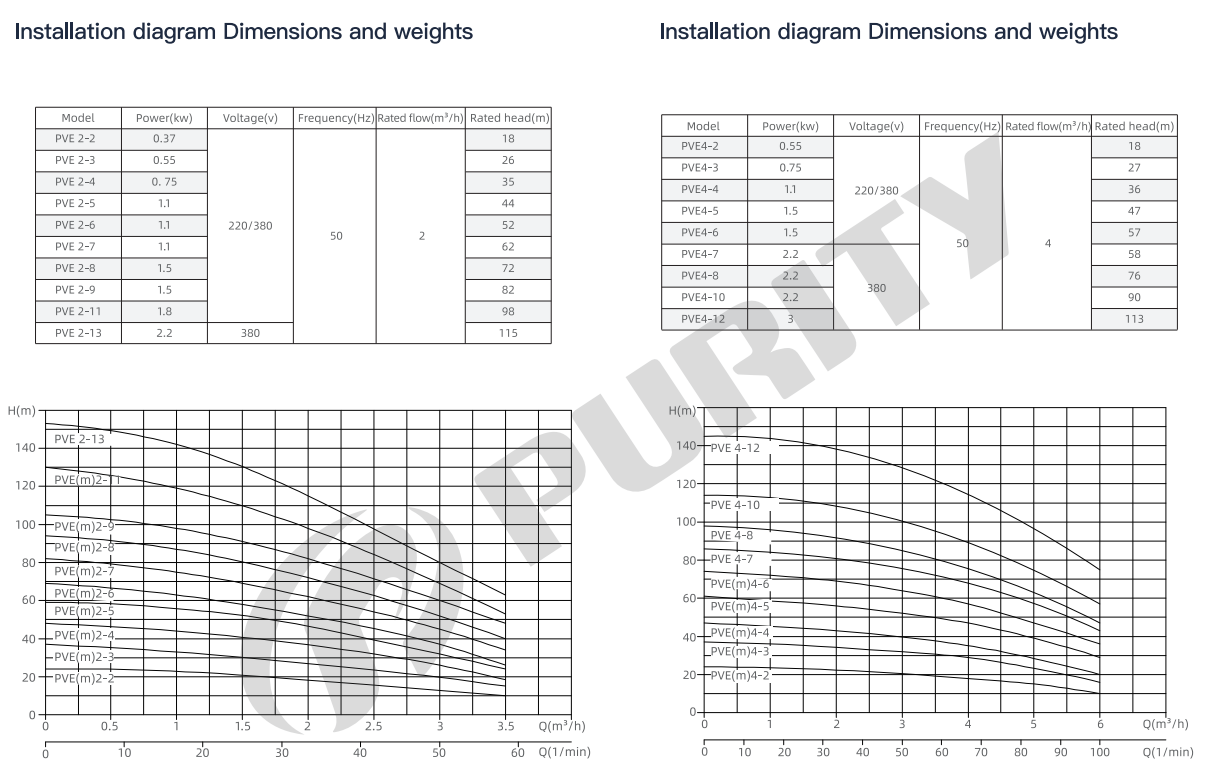

Figure | PVE vertical multistage pump

Purity’s latest PVE vertical multistage centrifugal pump introduces industryleading innovations, outperforming competitors with the following features:

1. Enhanced Performance: The PVE pump delivers 10%30% higher head under the same power and flow conditions, making it an excellent choice for highpressure applications.

2. Superior Materials: Manufactured using full copper winding and highperformance coldrolled silicon steel, the PVE pump ensures high efficiency, low energy loss, and minimal temperature rise.

3. Advanced Bearing Design: The upgraded front bearing increases axial load capacity compared to standard motors, enhancing durability and reliability.

These improvements position the PVE pump as a superior solution for demanding tasks, providing unmatched performance and operational efficiency.

Figure | PVE vertical multistage pump parameter

While multistage centrifugal pumps are versatile and efficient, selecting the right model depends on fluid characteristics and operational requirements. Purity’s PVE vertical multistage centrifugal pump stands out with its advanced design and performance enhancements, making it a top choice for highhead and highpressure applications.For inquiries or to explore how Purity’s PVE pump can meet your needs, contact our team of experts today.