An end suction pump is one of the most common and versatile types of centrifugal pumps used in water supply, HVAC, fire protection, and industrial systems. It is well known for its simple design, efficient performance, and easy maintenance. In this article, we’ll explore how end suction centrifugal pumps work, their structural features, key advantages, and why manufacturers like Purity Pump are leading the way in reliable and energy-efficient water solutions.

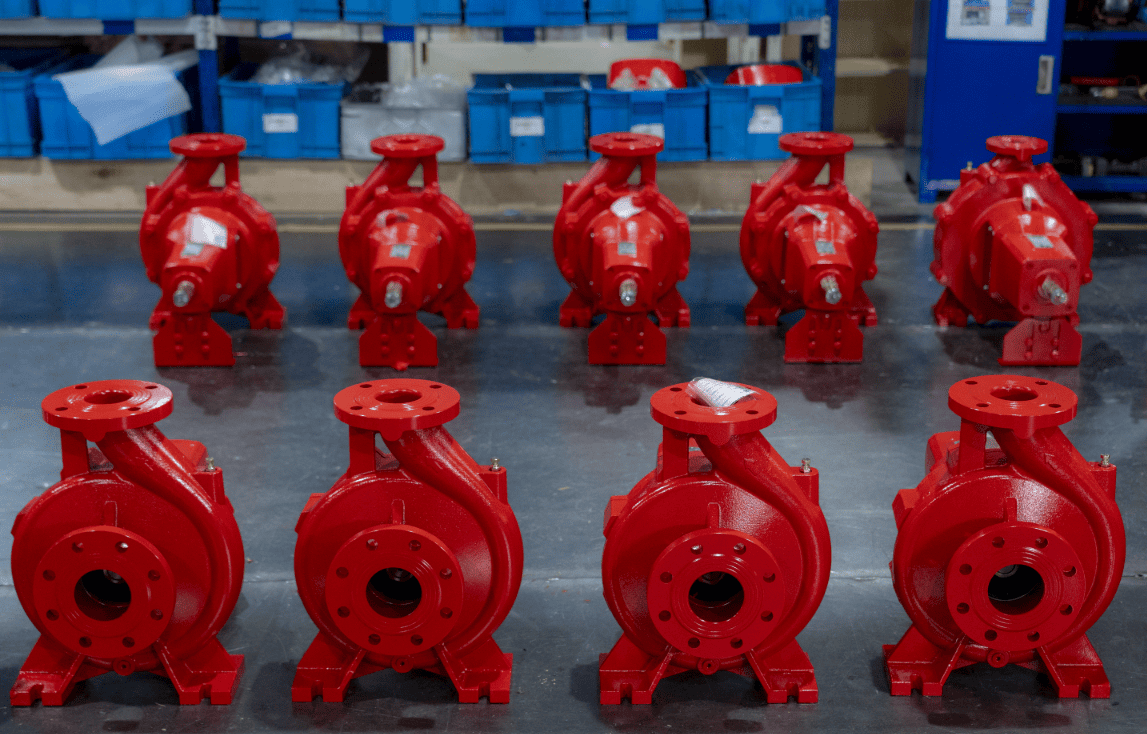

Figure | Actual photo of Purity PS end suction bare shaft pump

An end suction centrifugal pump is a single-stage centrifugal pump where the suction inlet is positioned at one end of the casing and the discharge outlet is at the top, forming a 90° angle. Inside the pump, a rotating impeller generates centrifugal force, pulling liquid in through the suction side and pushing it out through the discharge outlet under pressure.

This straightforward hydraulic mechanism allows the pump to handle large volumes of clean or lightly contaminated water efficiently. Depending on the installation requirements, the pump can be mounted horizontally or vertically, offering flexible configuration options for different systems.

End suction pumps have a compact yet accessible structure, making them highly convenient for inspection and repair. Most designs feature a horizontal shaft and back pull-out construction, which allows maintenance of the impeller and mechanical seal without disconnecting the suction or discharge piping.

Key configuration options include:

(1)Coupling type: Close-coupled or flexible-coupled designs

(2)Material selection: Cast iron, stainless steel, or corrosion-resistant alloys

(3)Performance range: Available in multiple diameters and power ratings to suit diverse operational needs

When compared with inline centrifugal pumps, end suction pumps require slightly more installation space but are much easier to maintain—making them a preferred choice in facilities where reliability and serviceability are priorities.

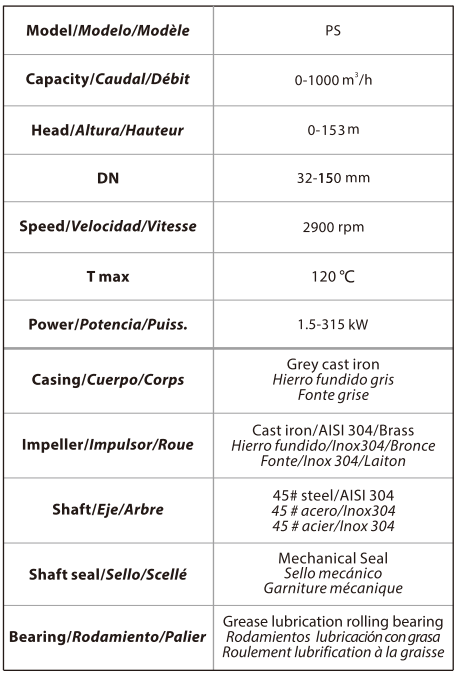

Figure | Purity PS end suction pump technical table

① High efficiency and energy savings:

Modern end suction centrifugal pumps are engineered with optimized hydraulic designs, ensuring smoother flow curves, reduced turbulence, and lower energy consumption. Many models meet international energy standards such as the U.S. DOE efficiency requirements.

② Reliable and durable operation:

With a sturdy structure and minimal moving parts, these pumps deliver consistent performance over long service life, ideal for continuous-duty applications in industrial and municipal systems.

③ Easy installation and maintenance:

Their modular design and readily accessible components significantly reduce downtime for inspection, part replacement, or motor servicing.

④ Cost-effective performance:

Low initial investment, long lifespan, and minimal maintenance needs make them one of the most economical solutions for fluid transfer.

⑤ Quiet and smooth running:

Reduced vibration and stable hydraulic balance allow the pump to operate quietly, making it suitable even for commercial and residential environments.

End suction centrifugal water pumps are widely used in:

(1)HVAC systems: Circulating chilled or cooling water in towers and air conditioning loops

(2)Water supply and boosting: Delivering pressurized clean water in residential and commercial buildings

(3)Firefighting systems: Serving as the main pump in sprinkler and hydrant installations

(4)Industrial processes: Handling process water in factories, chemical plants, and power stations

(5) Wastewater treatment: Managing liquids with small solid contents or light sludge

As one of the experienced end suction centrifugal pump manufacturers, Purity Pump offers the PS series—a robust and efficient solution for clean water and light industrial applications.

Key features include:

(1)Optimized inlet design: A larger inlet than outlet ensures ample water inflow, minimizes turbulence, and reduces cavitation for smoother and quieter operation.

(2)Advanced hydraulic simulation: Guarantees smooth performance curves, higher efficiency, and stable operation.

(3)Comprehensive range: Models available in multiple diameters, powers, and coupling styles to meet diverse requirements.

(4)Certified quality: All products are CE certified, ensuring global safety and reliability standards.

Figure | Purity PS end suction bare shaft pump

In summary, the end suction pump combines simplicity, efficiency, and versatility—making it the workhorse of modern water movement across HVAC, fire protection, municipal, and industrial systems. For most clean-water and moderate-pressure applications, an end suction centrifugal water pump provides an excellent balance of performance and economy.

However, for high-pressure, high-temperature, or high-viscosity fluids, users may consider multistage or inline pump alternatives. When properly selected and configured, an end suction pump ensures stable, efficient, and cost-effective operation for years to come.

With over 15 years of expertise in industrial energy-saving pumps and exports to more than 130 countries, Purity Pump continues to deliver high-performance end suction centrifugal pumps that power reliable water systems around the world. If you are interested in becoming a Purity distributor or partner, contact us today to join our global network.