A horizontal split case pump is a type of horizontal centrifugal pump widely used in municipal, industrial, and fire protection systems. Known for its high efficiency, durability, and easy maintenance, it is often referred to as the “workhorse” of fluid handling equipment. Compared with end-suction pumps or vertical turbine pumps, horizontal split case pumps are more stable under heavy-duty operation and are particularly suitable for applications that demand continuous, high-volume water delivery.

A horizontal split case pump is a centrifugal pump in which the casing is divided into two halves along the horizontal axis. This split casing design allows operators to easily remove the top half of the pump without disturbing the alignment of the suction and discharge piping. Maintenance, inspection, and part replacement can therefore be carried out efficiently.

The pump operates on the centrifugal principle: water enters the impeller eye, gains velocity from the rotating impeller, and is guided into the volute casing where velocity energy is converted into pressure energy. The pressurized fluid is then discharged through the pump outlet.

Key design features of horizontal split case pumps include:

(1)Split casing design – simplifies maintenance and inspection by allowing access to internal components without disconnecting pipework.

(2)Double suction impeller – draws liquid from both sides of the impeller, balancing hydraulic forces and reducing axial thrust. This results in smoother operation and extended bearing life.

(3)Shaft and bearings – the shaft is supported by bearings on both sides, ensuring stability and minimizing vibration.

(4)Volute casing – collects fluid from the impeller and directs it to the discharge nozzle.

(5)Mechanical seals or packing rings – prevent leakage along the shaft.

These structural features make the horizontal split case pump more efficient and durable compared with standard frame-mounted or end suction pumps.

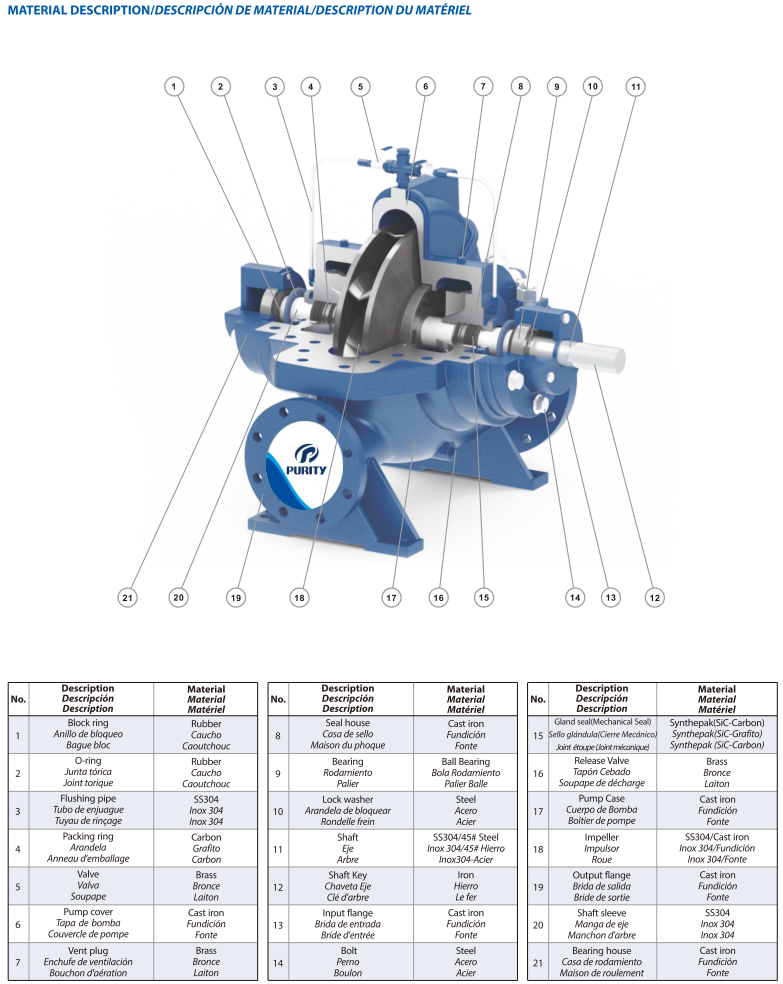

Figure | Purity Split Case Pump PSC Components

Horizontal split case pumps can be configured for different duties:

1. Single-stage pumps – capable of delivering flows up to 140,000 gallons per minute (gpm) with heads of around 550 feet. These are ideal for municipal water supply and HVAC systems.

2. Multi-stage pumps – designed for higher heads up to 2,200 feet and operating pressures of 740 psi. These pumps are used in heavy-duty and high-pressure applications such as power generation or long-distance water transmission.

3. Horizontal split case fire pumps – a specialized category of electric fire pumps that meet strict fire protection standards. They provide reliable, high-pressure water supply for sprinkler systems, hydrants, and fire suppression equipment.

The versatility of horizontal centrifugal pumps allows them to be used across a wide range of industries:

(1) Municipal water supply and distribution – transporting large volumes of water over long distances.

(2)Fire protection systems – horizontal split case fire pumps are widely used in NFPA-compliant fire pump packages.

(3)HVAC systems – circulating chilled and hot water in large commercial buildings.

(4)Industrial processes – handling clean water or low-viscosity fluids in chemical, petrochemical, and food processing plants.

(5)Power generation – cooling water circulation and boiler feed operations.

(6)Agricultural irrigation – distributing water across large-scale farmlands.

Horizontal split case pumps provide multiple performance benefits:

1. High efficiency – efficiency levels often exceed 90%, making them energy-saving solutions.

2. Stable operation – with bearings on both sides of the impeller, the pump runs smoothly with reduced vibration.

3. Durability – designed for long service life, often operating reliably for decades.

4. Easy maintenance – the split casing design allows rapid access for inspection and replacement of internal parts.

5. Improved suction performance – double suction impellers reduce net positive suction head required (NPSHr), minimizing cavitation risks.

6. Quiet operation – modern models, such as the Purity PSCM horizontal split case pump, incorporate low-noise design features for quieter environments.

While horizontal split case pumps offer many advantages, there are some considerations:

(1)Higher cost – they are more expensive upfront compared with end suction pumps.

(2)Space requirements – horizontal models need more floor space for installation and maintenance access.

(3)Fluid limitations – not suitable for thick, viscous liquids or slurries with solids.

(4)Professional installation – due to their complexity, correct alignment and setup require skilled technicians.

Figure | Purity Split Case Pump PSCM

When reliability, efficiency, and long service life are top priorities, horizontal split case pumps remain the preferred choice. In particular, horizontal split case fire pumps play a critical role in life safety by ensuring consistent water pressure during fire emergencies.

Companies like Purity specialize in energy-efficient industrial pumps, including the PSCM horizontal split case pump, which offers excellent suction performance, low noise, and stable operation. With international certifications such as CE, ISO, and SASO, Purity pumps are exported to more than 130 countries worldwide and are trusted across industries.

A horizontal split case pump is more than just another centrifugal pump—it is a dependable, high-efficiency solution for applications that demand continuous operation and large-volume water movement. Whether installed in municipal water systems, HVAC plants, or as an electric fire pump in critical fire protection systems, horizontal split case pumps continue to set the benchmark for durability, performance, and reliability.

If you are considering a pump for long-term, heavy-duty use, a horizontal split case pump is one of the most reliable investments you can make.