When it comes to fluid transportation under demanding conditions, one of the most common questions engineers and operators ask is: “Are centrifugal pumps high pressure?” The answer is yes — with the right design and configuration, centrifugal pumps can be manufactured to handle very high system pressures. Among these, the high pressure centrifugal pump and the multistage centrifugal pump stand out as reliable solutions for industries requiring powerful and efficient fluid handling.

A high pressure centrifugal pump is a pump specifically engineered to deliver fluid at high discharge pressures, typically within a system pressure range of PN25 to PN160. Unlike standard pumps that may only be suitable for moderate conditions, high pressure centrifugal pumps are reinforced in terms of materials, structure, and sealing systems to ensure long-lasting performance.

These pumps are often used in applications such as water treatment, filtration, reverse osmosis, and industrial cleaning, where stable and reliable pressure is essential for system operation.

Built with stainless steel or similar high-strength materials, these pumps are highly resistant to corrosion, rust, and wear.

The rugged housing design ensures operational safety, even under continuous high-pressure cycles.

Equipped with either single mechanical seals or double mechanical seals (in flushed, tandem, or back-to-back arrangements).

Advanced sealing prevents leakage and extends pump service life in harsh environments.

Simplified structural design allows quick seal replacement without special tools.

Reduced downtime means lower maintenance costs and improved system reliability.

Improved impeller and volute geometry ensures pump efficiency up to 78%.

This results in significant energy savings in continuous operation.

Suitable for handling water, chemicals, and solutions with alkalis or certain acids.

Ideal for water treatment, industrial cleaning, and filtration processes.

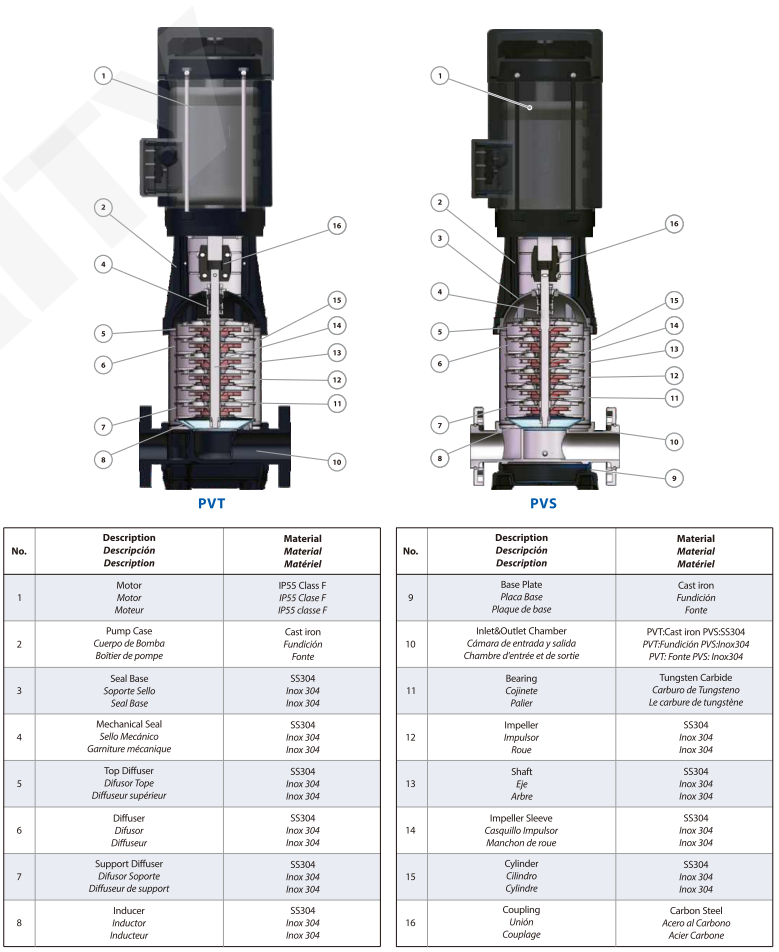

Figure | Purity High Pressure Multi-stage Pump PVS Components

While single-stage pumps are efficient for moderate heads, industries often require pumps that can deliver much higher heads without compromising efficiency. This is where the multistage centrifugal pump comes into play.

A high pressure multistage centrifugal pump uses multiple impellers in series, each stage boosting the pressure further. This makes them the go-to choice for high-rise buildings, boiler feed systems, and reverse osmosis water treatment, where pressures can reach exceptionally high levels.

Among multistage designs, the vertical multistage centrifugal pump has gained popularity due to its compact footprint and ability to handle corrosive or high-temperature fluids. With vertical installation, the pump saves floor space, making it highly practical for industrial facilities and commercial buildings.

The Purity PVS vertical multistage centrifugal pump represents the advantages of modern pump engineering:

Applications of High Pressure Centrifugal Pumps

Figure | Purity High Pressure Mmultistage Pump PVS

So, are centrifugal pumps high pressure? Absolutely. With advanced designs like the high pressure centrifugal pump, centrifugal high pressure pump, and especially the high pressure multistage centrifugal pumps — including compact vertical multistage centrifugal pumps — industries now have reliable, efficient, and durable solutions for demanding applications.

For businesses looking to improve energy efficiency, safety, and performance, choosing the right high pressure centrifugal pump is essential. And with proven products like the Purity PVS series, operators can trust in long-term reliability backed by international certification.