When selecting a pump for commercial, industrial, or high-hygiene applications, material choice plays a critical role in performance, service life, and reliability. Among the many pump materials available, stainless steel stands out for its exceptional corrosion resistance, mechanical strength, and versatility. Whether you need a stainless steel centrifugal pump, a stainless steel centrifugal water pump, or heavy-duty industrial stainless steel centrifugal pumps, the benefits of choosing stainless steel are clear.

One of the most important advantages of a stainless steel pump is its superior corrosion resistance compared to pumps made from cast iron or plastic. This makes stainless steel an ideal choice for conveying weak acids, weak alkalis, salts, and other corrosive or slightly corrosive liquids.

Thanks to its inherent material properties, stainless steel can operate stably even in high-humidity, salt-laden, or chemically aggressive environments. For industries such as food and beverage, pharmaceuticals, water treatment, and chemical processing, this environmental adaptability ensures the pump maintains optimal performance over many years.

Durability is a major selling point of any stainless steel water pump. Made from high-strength stainless steel, these pumps offer exceptional structural integrity, wear resistance, and impact resistance. They are far less prone to deformation, cracking, or premature failure than pumps made from softer materials.

Because of this strength, stainless steel centrifugal pumps have low failure rates, require minimal maintenance, and can operate reliably for decades when properly maintained. This translates into lower lifecycle costs, even if the initial investment is slightly higher than alternatives.

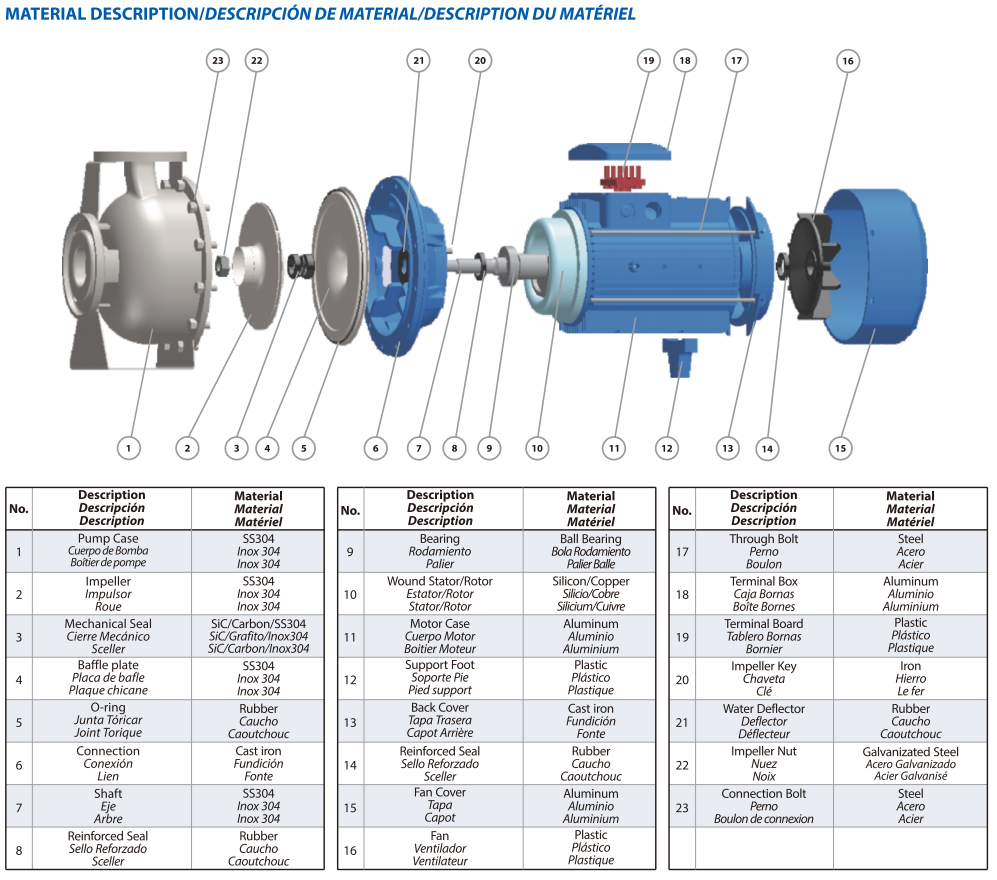

Figure | Purity PZ Stainless Steel Centrifugal Pump Accessories

Stainless steel centrifugal pump manufacturers design their products to handle a broad range of fluids — from clean tap water to various industrial liquids. They are suitable for both non-corrosive and mildly corrosive liquids and can transport fluids at temperatures up to 120°C.

Applications include:

Compared to cast iron, stainless steel is lighter for its strength, making industrial stainless steel centrifugal pumps easier to transport, install, and maintain. The sleek, smooth surface is not only more visually appealing but also easier to clean, which is essential in hygiene-sensitive applications.

Stainless steel pumps also tend to produce lower noise during operation, have a compact footprint, and offer a longer lifespan. While their price may be slightly higher than plastic or cast iron pumps, their durability, low maintenance requirements, and efficiency deliver excellent value over time.

While stainless steel is corrosion-resistant, it is not corrosion-proof. Long-term exposure to high-chloride environments, such as seawater or heavily chlorinated water, can still cause damage. In such cases, special alloys or protective coatings may be necessary.

Additionally, stainless steel pumps are heavier than plastic pumps, which may be a factor in certain lightweight or portable applications.

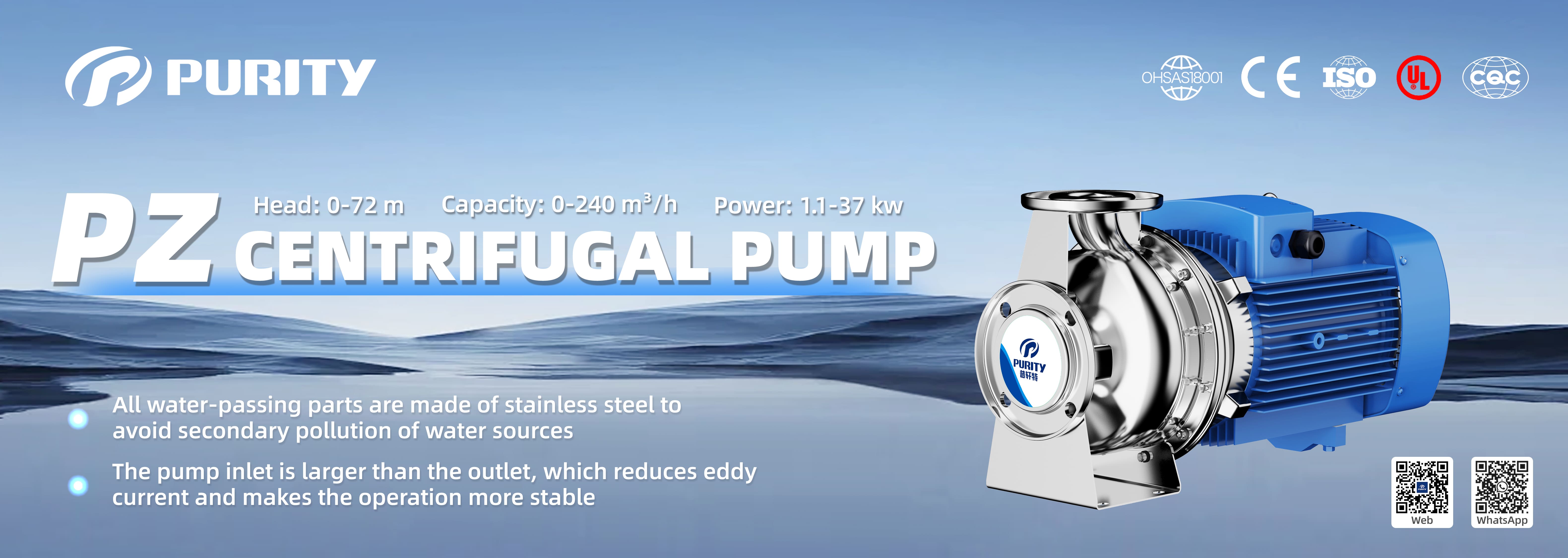

As one of the experienced stainless steel centrifugal pump manufacturers, Purity offers the PZ stainless steel centrifugal water pump, which incorporates multiple performance-enhancing features:

Optimized inlet and outlet design – The pump inlet diameter is larger than the outlet diameter, reducing turbulence and lowering the net positive suction head (NPSH) requirement. This ensures smoother, quieter operation and reduces the risk of cavitation.

High-efficiency motor – Equipped with an energy-efficient motor as standard, delivering reliable performance while reducing energy consumption.

Full stainless steel wetted parts – All fluid-contacting components are made from stainless steel, ensuring hygiene, environmental compliance, and superior corrosion resistance.

Robust construction – IP55 protection class, F-class enameled wire for durability, and a complete range of models to suit different operating conditions.

The Purity PZ stainless steel centrifugal pump has achieved international certifications, including CE and ISO, and is backed by over 15 years of manufacturing and global sales experience. Tested by time and customers worldwide, it represents a reliable choice for both industrial and commercial operations.

Figure | Purity PZ Stainless Steel Centrifugal Pump

Whether your priority is corrosion resistance, durability, hygiene, or operational stability, stainless steel pumps excel in nearly every aspect. By selecting a stainless steel water pump from a trusted manufacturer, you ensure:

If you are looking for high-quality industrial stainless steel centrifugal pumps, Purity can provide proven solutions tailored to your application. Contact us today to learn more or to become an authorized distributor in your region.