Centrifugal pumps are one of the most widely used types of pumps in the world, known for their simple structure, high efficiency, and versatility. From fire protection to industrial processes and municipal water supply systems, centrifugal pumps play a critical role in ensuring reliable fluid transport across a wide range of applications. But what are centrifugal pumps best for? This article explores the core uses, common pump types, and selection tips for centrifugal pumps in key sectors.

In fire protection, centrifugal pumps are the backbone of any sprinkler or hydrant system. When an emergency strikes, these pumps ensure a stable, high-pressure water supply that allows fire suppression equipment to respond quickly and effectively.

(1) End Suction Centrifugal Pump: Compact and easy to maintain, ideal for small to medium-sized buildings.

(2)Vertical Multistage Pump: Offers high head performance, suitable for high-rise buildings or industrial plants.

(3)Split Case Pump: Known for high flow rates, low vibration, and easy servicing. Often used in municipal or heavy industry fire main systems.

(1)Must comply with NFPA 20 or local fire codes

(2)Redundant design options (e.g., diesel pump + electric pump)

(2)Cavitation resistance and rapid response features

Purity, a trusted centrifugal pump supplier, offers a wide range of fire pumps including end suction, vertical multistage, and split case models. Their products ensure compliance with international standards and deliver reliable performance in emergency scenarios.

Figure | Purity Fire Pump Series

In industries such as petrochemicals, pharmaceuticals, food processing, pulp and paper, power generation, and HVAC, industrial water pumps are essential for transporting fluids like water, oil, chemicals, and slurries. Centrifugal pumps are favored for their robust design, adaptability, and cost-effectiveness.

(1)API 610 Pumps: Designed for oil & gas sectors, handling high-temperature, high-pressure fluids.

(2)ANSI Pumps: Standardized construction, suitable for chemical processing applications.

(3)Stainless Steel, Multistage, and Magnetic Drive Pumps: Perfect for corrosive, flammable, or high-purity media.

(1)Fluid properties like viscosity, density, corrosiveness, and solids content

(2)High efficiency and low maintenance for long-term operation

(3)Reliable sealing and bearing systems to prevent leakage and overheating

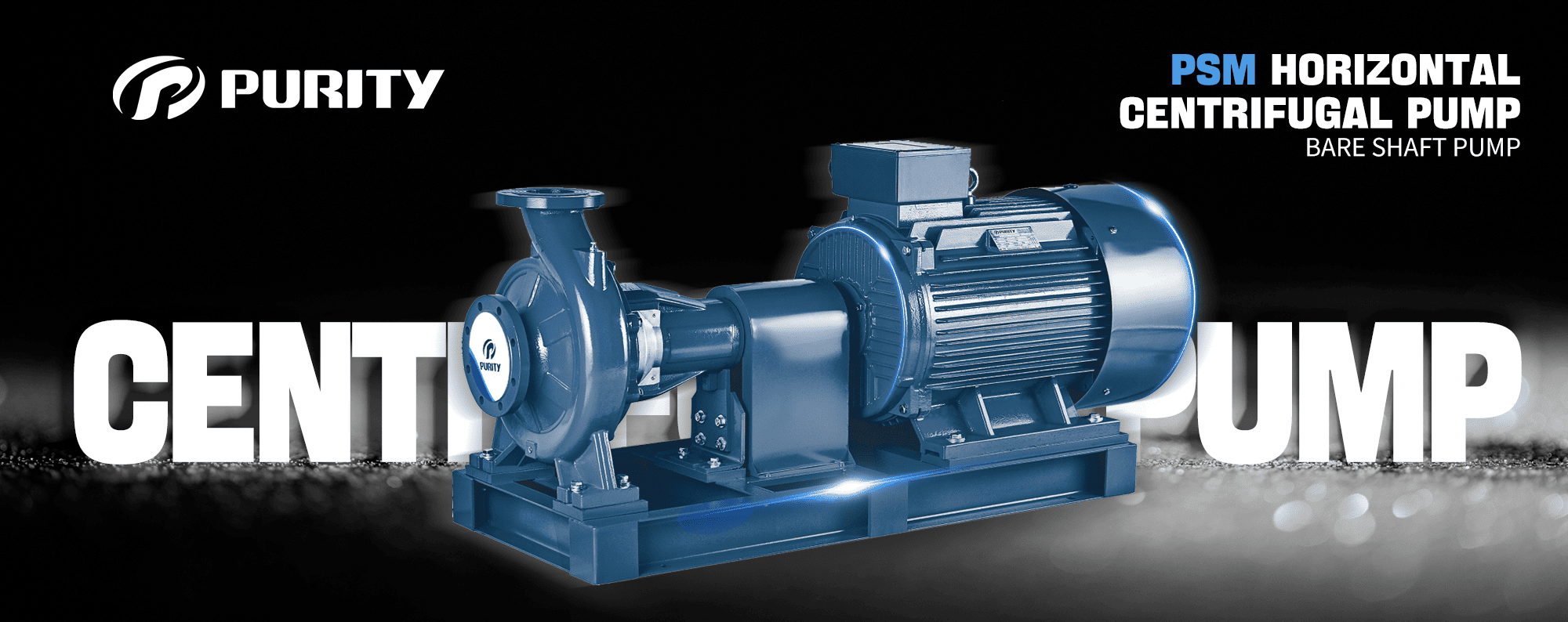

With over 15 years of experience in centrifugal pump manufacturing, Purity has become a globally recognized brand. Their end suction centrifugal pump series (PSM) is highly energy-efficient, equipped with national standard motors, and available in a wide range of models to suit diverse industrial needs.

In the public and residential sectors, centrifugal pumps are widely used to provide clean water for drinking, irrigation, and municipal distribution networks. Their efficiency, scalability, and ease of maintenance make them a preferred choice for these applications.

(1)End Suction Centrifugal Pump: Ideal for building-level supply or secondary water boosting.

(2)Vertical Multistage Pump: Suitable for long-distance transmission in high-rise buildings or municipal water plants.

(3)Axial Flow and Mixed Flow Pumps: High flow rates for irrigation and large-scale city water projects.

(1)Adaptability to fluctuating flow demands

(2)Must match system pressure losses, suction head, and total dynamic head

(3)Energy-saving and easy maintenance features are essential for long-term use

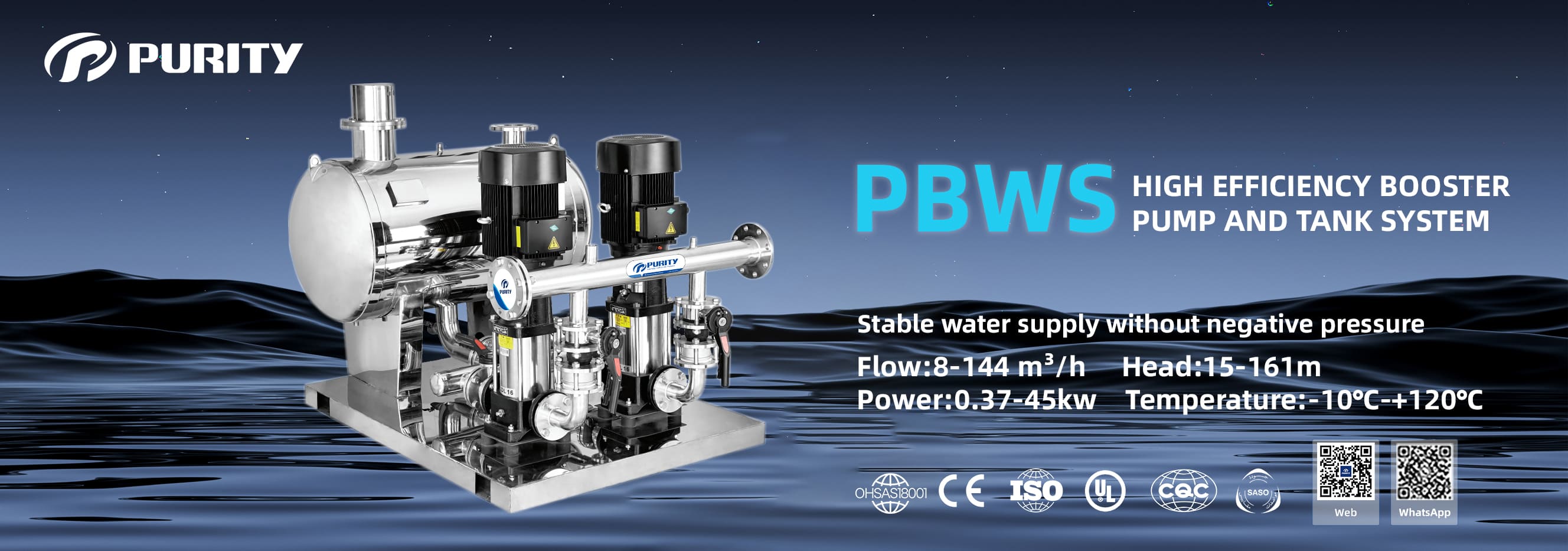

Whether used in urban buildings, agricultural irrigation, or rural water systems, Purity’s range of centrifugal pumps meets the challenge of stable, efficient, and scalable water delivery.

Figure | Purity Water Supply System

|

Application |

Common Types |

Key Requirements |

Standards/Recommendations |

|

Fire Protection |

End Suction, Split Case, Multistage |

High reliability, redundancy, code compliance |

NFPA 20, anti-cavitation |

|

Industrial |

ANSI, API, Multistage |

Adaptable, high efficiency, safe sealing |

API 610, ANSI B73.1 |

|

Water Supply |

End Suction, Vertical Multistage, Axial Flow |

Large flow, energy efficiency, easy service |

Building pressure boost, municipal supply, irrigation |

Purity is a specialized manufacturer of industrial centrifugal pumps with exports to over 120 countries. Their flagship product, the PSM end suction centrifugal pump, stands out for its high efficiency, broad model range, and compliance with international energy standards.

Key Benefits:

(1)Energy-efficient national standard motors

(2)Wide range of specifications to meet all demands

(3)Strong R&D and 15+ years of manufacturing expertise

Purity is actively seeking international distributors for its centrifugal pump line. If you're looking for a reliable centrifugal pump supplier with proven quality and global support, Purity could be your ideal partner.

Figure | Purity End Suction Centrifugal Pump PSM

Conclusion:

Centrifugal pumps are best for applications that require efficient, reliable, and scalable fluid transport. Whether you’re dealing with firefighting systems, complex industrial processes, or municipal water networks, choosing the right type of centrifugal pump—like an end suction pump, vertical multistage pump, or split case pump—is key to long-term success. Contact a trusted supplier like Purity to get expert guidance and high-performance pump solutions tailored to your needs.