Centrifugal pumps are essential in industries such as water treatment, oil & gas, and chemical processing. Proper maintenance ensures efficiency, longevity, and reduced downtime. This guide covers centrifugal pump maintenance, including centrifugal water pumps, industrial centrifugal pumps, centrifugal pump mechanical seals, and best practices from leading centrifugal pump suppliers.

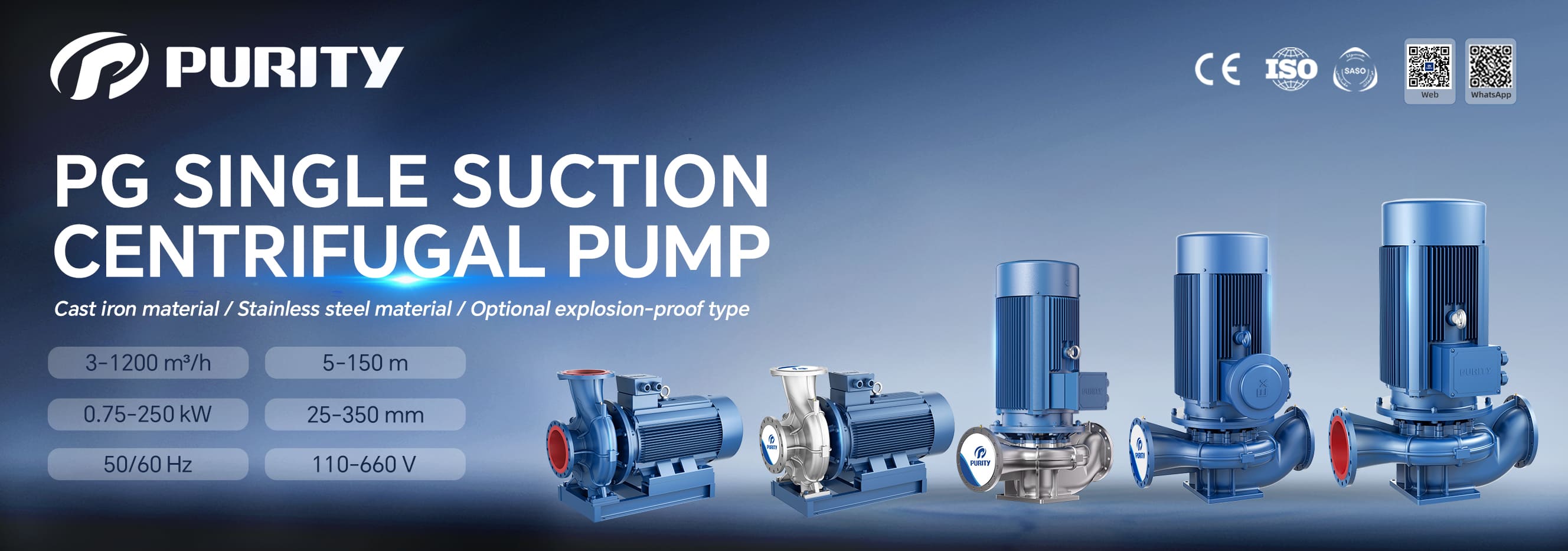

Figure | Purity Centrifugal Pump Full Range

Centrifugal pumps move fluids by converting rotational energy into hydrodynamic flow. Without proper maintenance, issues like seal leaks, bearing failures, and impeller damage can lead to costly breakdowns. A structured maintenance plan improves:

- Reliability – Reduces unexpected failures.

- Efficiency – Maintains optimal flow and pressure.

- Safety – Prevents hazardous leaks (critical in chemical industries).

Key Components Requiring Maintenance

1. Centrifugal Pump Mechanical Seal

The centrifugal pump seal prevents fluid leakage. Common maintenance steps:

- Daily/Weekly: Check for leaks, inspect seal faces for wear.

- Monthly: Verify flush system operation (critical in high-temperature pumps).

- Annually: Replace seals if worn (use hard alloy or silicon carbide seals for durability).

Pro Tip: Leading centrifugal pump suppliers like Purity use advanced materials to extend seal life.

2. Bearings

- Lubrication: Use the correct oil/grease type and replace per schedule.

- Monitoring: Track vibration and temperature (high readings indicate wear).

- Replacement: Check for play or noise annually.

3. Impeller & Casing

- Erosion/Cavitation: Inspect for pitting or corrosion (common in centrifugal water pumps).

- Clearance Check: Ensure proper gap between impeller and wear ring.

4. Pipeline Centrifugal Pump Support

- Vibration Analysis: Loose mounts cause misalignment.

- Bolt Tightening: Prevent structural fatigue.

Modern industrial centrifugal pumps use:

- Vibration Sensors – Detect early bearing failure.

- Thermal Imaging – Identify overheating seals.

- AI Analytics – Predict failures before they occur.

When selecting a pipeline centrifugal pump series-PG, consider:

✔ Material Quality (e.g., corrosion-resistant alloys)

✔ Seal Technology (mechanical vs. gland packing)

✔ Certifications (ISO, CE)

Figure | Purity Pipeline Centrifugal Pump

Purity Pumps stand out with:

- Compact & stable design (reduces vibration)

- Superior sealing (hard alloy/carbon-silicon seals)

- 15+ years of industry expertise

Effective centrifugal pump maintenance involves preventive checks, seal monitoring, and predictive technologies. Whether you use centrifugal water pumps or high-pressure industrial models, a structured approach minimizes downtime.

Looking for durable centrifugal pump suppliers? Purity offers reliable, certified pumps with extended service life. Contact us for global partnership opportunities!