Centrifugal pumps are the backbone of modern fluid transport systems, powering industries, agriculture, and daily life. But where exactly are centrifugal pumps used, and how do they work? This guide explores the working principle of centrifugal pumps, their diverse types, and key applications—from water supply to heavy industry. We’ll also highlight why leading industrial centrifugal pump manufacturers like Purity stand out in this competitive field.

The working principle of a centrifugal pump relies on converting rotational energy into fluid flow:

1. Priming: The pump casing fills with liquid to remove air.

2. Impeller Action: A high-speed rotating impeller creates centrifugal force, flinging fluid outward.

3. Pressure Conversion: The volute casing transforms kinetic energy into static pressure.

4. Continuous Flow: Fluid exits at high pressure via the discharge pipe.

Key components include the impeller, volute, shaft, and seals. Unlike positive displacement pumps, centrifugal pumps excel in high-flow, low-viscosity applications.

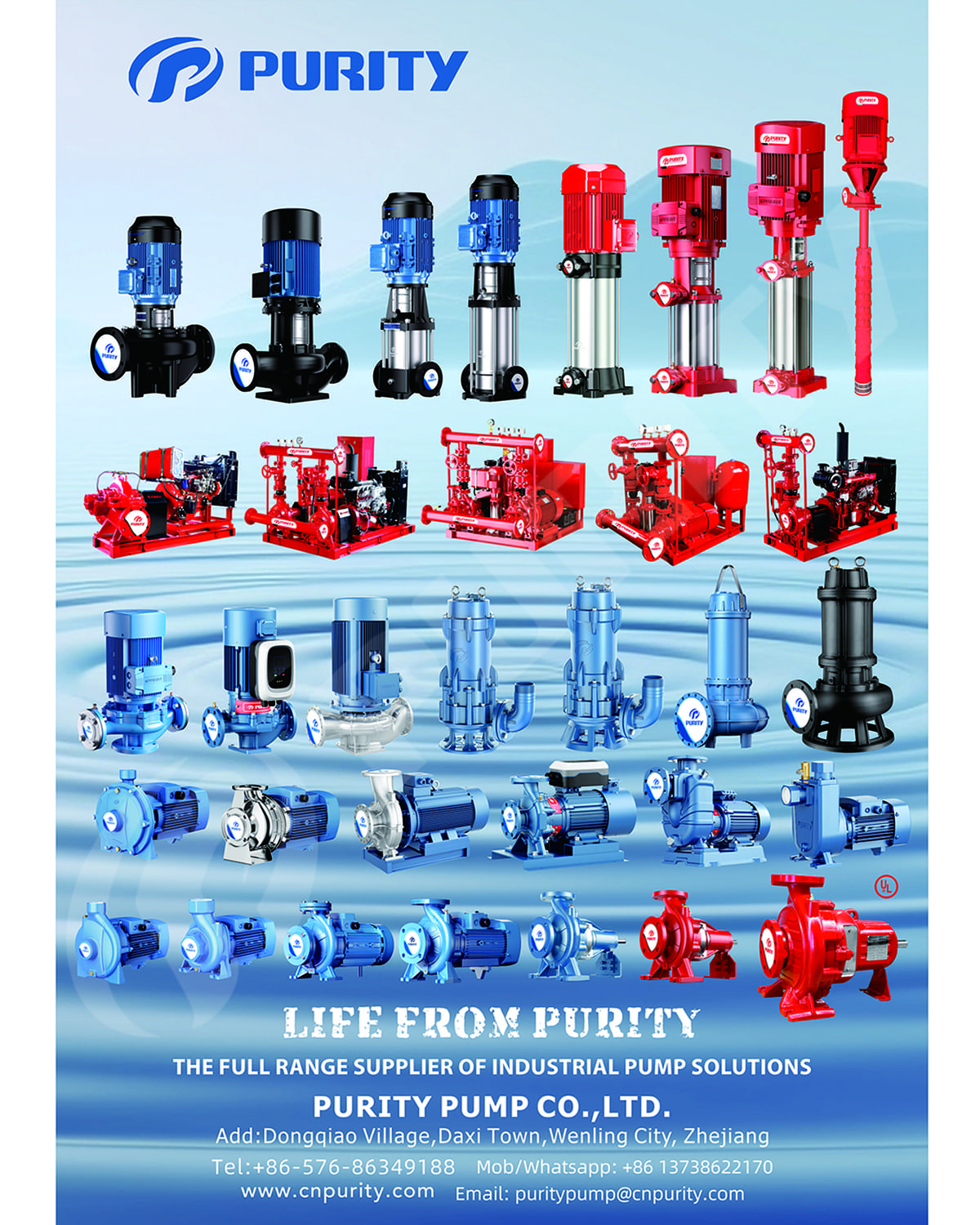

Figure | Purity full range of products

Centrifugal pumps come in multiple designs for specialized tasks:

- By Flow Direction:

- Radial Flow: High pressure, low flow (e.g., multistage pumps for deep wells).

- Axial Flow: High flow, low pressure (e.g., ship propulsion pumps).

- Mixed Flow: Balanced pressure and flow (e.g., irrigation pumps).

- By Stages:

- Single-Stage: Simple design for moderate pressure.

- Multi-Stage: Multiple impellers for extreme pressures (e.g., boiler feed pumps).

- By Configuration:

- Horizontal/Vertical: Space-saving vs. ease of maintenance.

- Open/Closed Impellers: For clean or solids-laden fluids.

Leading industrial centrifugal pump manufacturers like Purity offer all these variants, including CE-certified models for global standards.

Centrifugal pumps dominate these critical sectors:

1. Water & Wastewater

- Centrifugal water pumps deliver potable water in municipal systems.

- Wastewater plants use corrosion-resistant pumps for sludge handling.

2. Oil & Gas

- Transport crude oil, refined products, and drilling fluids.

3. HVAC & Heating

- Circulate water in closed-loop systems (e.g., radiators, chillers).

4. Agriculture

- Irrigation pumps combat terrain challenges with high-head designs.

5. Mining & Industry

- Handle abrasive slurries and dewater mines.

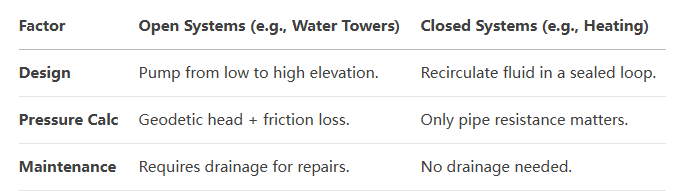

Open vs. Closed Systems: Key Differences

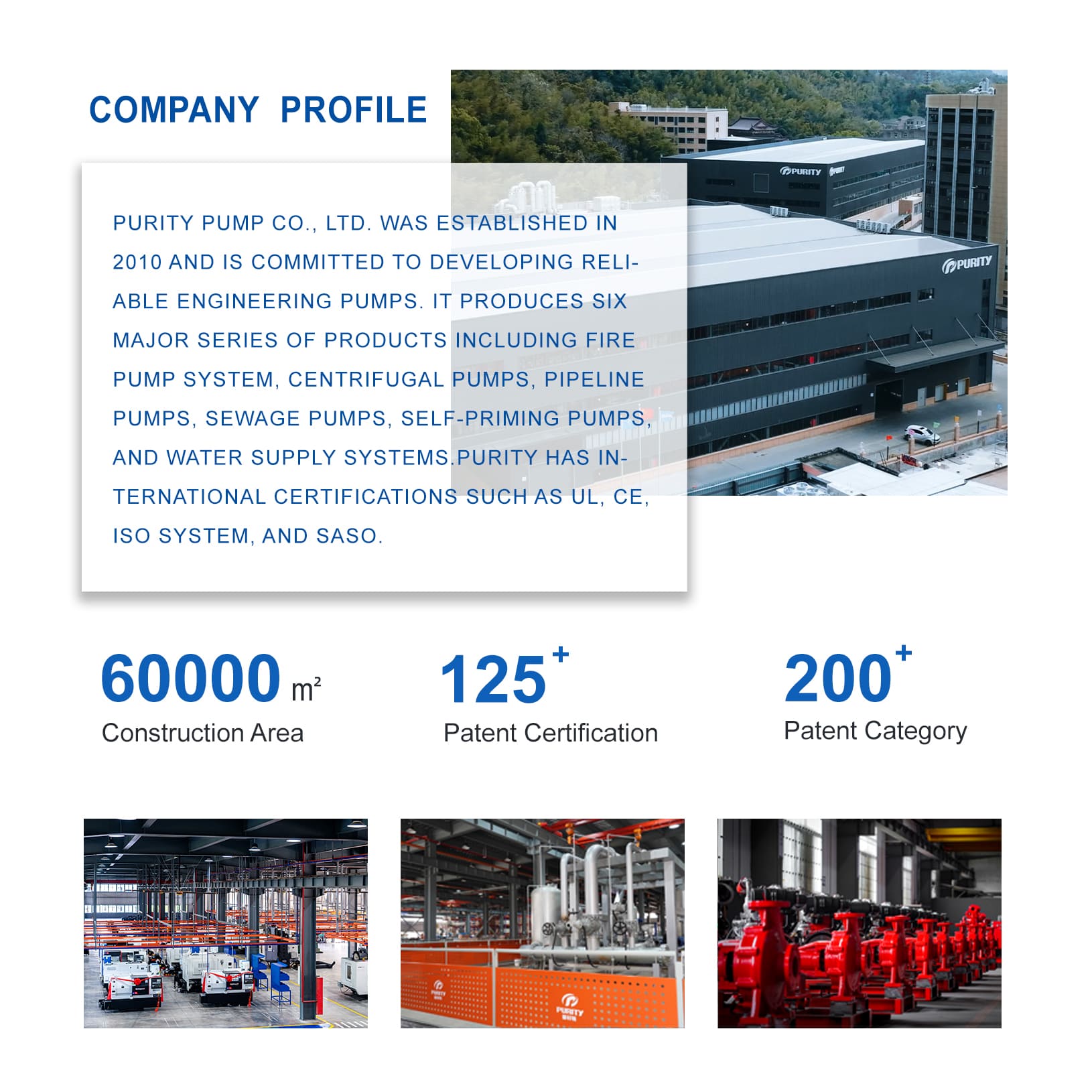

As a top-tier industrial centrifugal pump manufacturer, Purity offers:

✅ 15+ years of expertise in energy-efficient designs.

✅ Wide range (open/closed, single/multi-stage, horizontal/vertical).

✅ CE-certified pumps for reliability.

✅ Smart solutions (IoT monitoring, VFD controls).

Figure | Introduction to Purity

From centrifugal water pumps in cities to heavy-duty industrial applications, these pumps are indispensable. Understanding the types of centrifugal pumps and their working principles helps select the right model. For cutting-edge performance, trust Purity—where innovation meets durability.