Selecting the right pump is a crucial decision across industries, ensuring system efficiency and cost-effectiveness. Two commonly compared options are end suction pumps and inline pumps, each offering distinct advantages. This article highlights their key differences and helps guide your choice.

End Suction Pumps feature a horizontal design, with the inlet aligned axially and the discharge outlet perpendicular to the suction. The horizontal shaft allows for robust, traditional construction, making it suitable for submerged applications. This design helps facilitate smooth fluid flow, especially in municipal or industrial systems.

Inline Pumps, on the other hand, have a vertical structure, with the inlet and discharge points on the same axis. This vertical orientation makes inline pumps more compact, allowing for installation in confined spaces. Their alignment with piping systems makes them ideal for applications with limited floor space, such as HVAC systems.

End Suction Pumps require more floor space due to their horizontal setup. This can be a limitation in tight industrial settings, though they are easier to install and maintain. However, their efficiency drops under high-pressure or high-flow conditions, where they may not perform as well as inline pumps.

Inline Pumps have a much smaller footprint and perform better in high-flow, high-pressure environments. Their vertical design enhances hydraulic efficiency, making them suitable for demanding applications, especially where space is a concern.

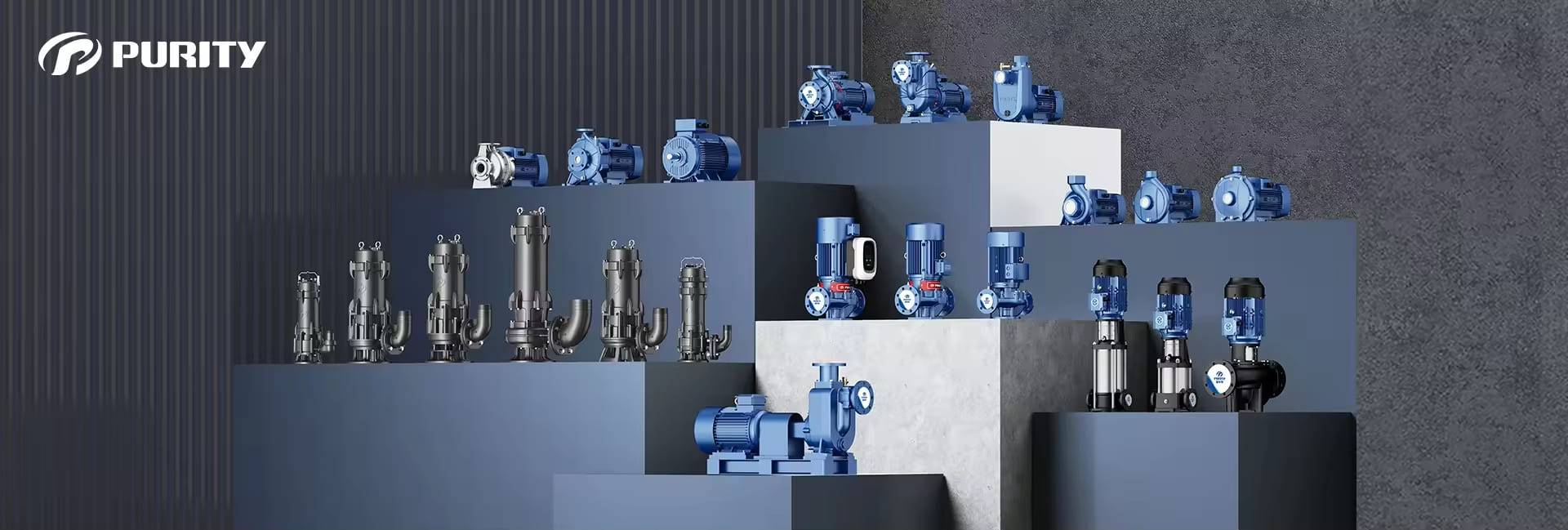

Picture|Purity Pump

End Suction Pumps often come with self-priming capabilities, allowing them to evacuate air and begin operation without additional priming systems. This makes them user-friendly in situations where priming might be cumbersome.

Inline Pumps generally lack self-priming capabilities. They require a flooded suction or an external priming system to operate, which adds complexity to installation, especially in fluctuating liquid-level environments.

End Suction Pumps are easier to maintain because their horizontal design allows quick access to internal components. Parts like the impeller and seals can be serviced without major disassembly, minimizing downtime in industries that require frequent maintenance.

Inline Pumps are more difficult to service due to their vertical structure. Accessing key components often involves separating the motor from the volute. However, they typically require less frequent maintenance, which can be beneficial in the long run.

End Suction Pumps are versatile and commonly used in water supply, sewage treatment, and chemical handling. They are well-suited for residential, commercial, and industrial applications, particularly where easy maintenance is prioritized.

Inline Pumps are preferred in HVAC, cooling water circulation, and industrial booster systems. Their compact design and ability to handle high temperatures and pressures make them ideal for space-constrained environments like thermal power plants.

Purity’s end suction pumps are UL-certified, meeting high safety and performance standards. They come in a wide range of models to suit different customer needs, offering flexibility in terms of power options and motor pairings, ensuring reliable performance across various applications.

Picture|Purity End Suction Pump PS

The choice between an end suction pump and an inline pump depends on the specific application. End suction pumps are ideal for general-purpose, low-pressure, high-flow systems where ease of maintenance is important. Inline pumps excel in high-pressure environments with limited space, delivering greater efficiency.

For most users, Purity’s UL-certified end suction pumps, with their flexibility and reliability, are a compelling option. Contact us today to learn more or get assistance selecting the right pump for your needs!