When selecting the right pump for your industrial, agricultural, or water management needs, understanding the difference between single suction (end suction) and double suction pumps is crucial. Both types of centrifugal pumps offer distinct features, advantages, and limitations, making them suitable for different applications. This article provides a comprehensive comparison to help you make an informed decision.

The fundamental difference between single suction pumps and double suction pumps lies in their structural design and how they manage fluid intake.

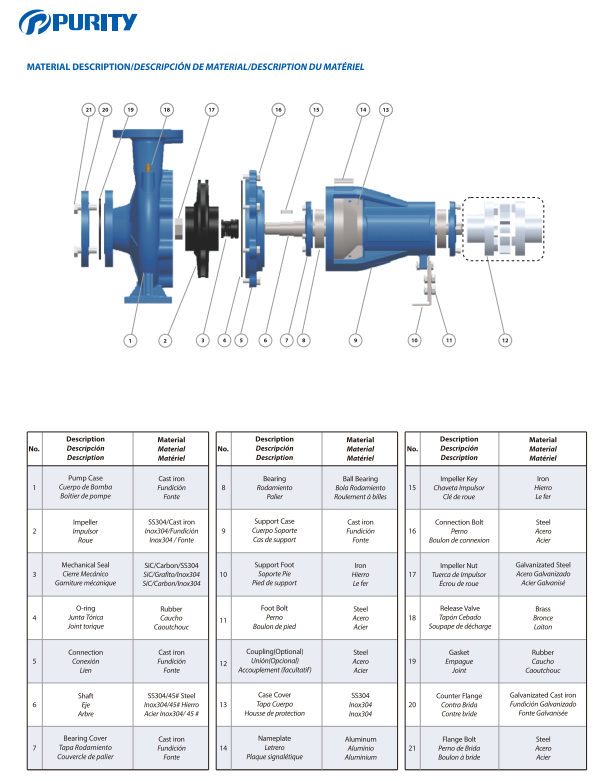

Single Suction Pumps (End Suction Pumps): In single suction pumps, fluid enters the impeller from one side. The design is simple, compact, and easy to install. These pumps are typically smaller in size and more suited to applications that require lower flow rates. Since the impeller only draws fluid from one side, the axial thrust is higher, which increases the load on the bearings and can lead to more wear over time. Single suction pumps are commonly used in agricultural systems or smaller engineering projects that don't demand high flow rates.

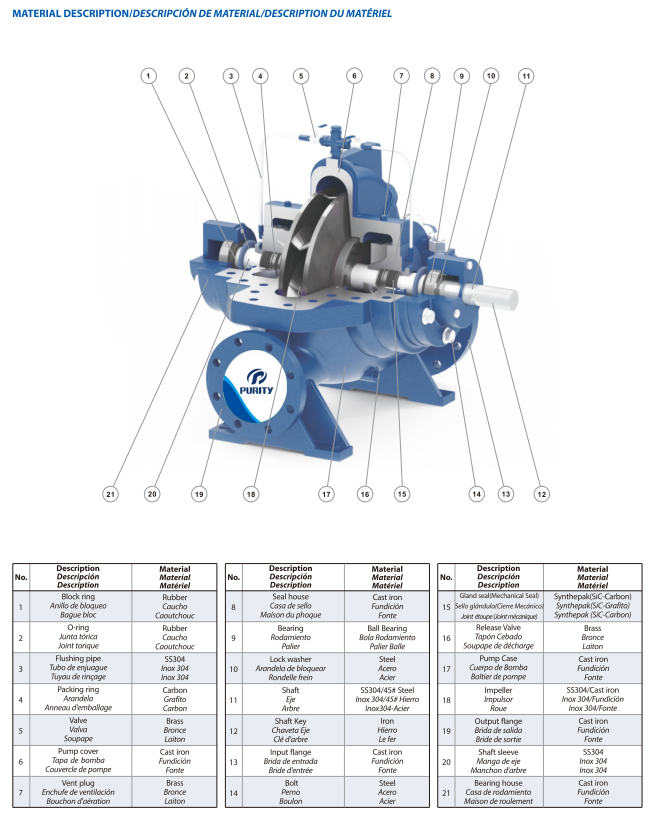

Double Suction Pumps: On the other hand, double suction pumps have a more sophisticated design, where fluid enters the impeller from both sides. This symmetrical design helps balance the axial thrust, resulting in smoother operation and less wear on the pump's components. The dual inlet design effectively doubles the flow capacity compared to a similarly sized single suction pump, making them ideal for applications requiring large flow rates. Due to their more complex design, double suction pumps are commonly used in large-scale projects such as municipal water supply, mining, and large infrastructure projects.

Figure | Purity PSC double suction pump parts

When it comes to performance, both types of pumps offer unique benefits, making them suitable for specific applications.

Single Suction Pumps:Single suction pumps are efficient in handling smaller flow rates, and their simpler structure makes them easier to maintain and repair. They are cost-effective solutions for smaller-scale projects or for systems that don't require continuous high-capacity flow. However, the axial thrust in single suction pumps can cause more stress on the bearings, which leads to increased maintenance needs over time. Additionally, their limited size makes them less suitable for large-scale applications.

Double Suction Pumps: The dual-sided intake design of double suction pumps allows them to handle larger volumes of fluid without increasing the size of the impeller. This design also ensures more balanced operation, reducing wear and tear, especially in high-capacity systems. Double suction pumps can operate for longer periods without the need for frequent maintenance, making them ideal for demanding applications. However, these benefits come with a higher initial cost compared to single suction pumps. In the long run, though, the durability and reliability of double suction pumps can offer significant cost savings, especially in high-flow applications.

The applications for single suction and double suction pumps vary significantly due to their differences in design and performance.

Single Suction Pumps: These pumps are commonly used in agriculture, small-scale irrigation, and light industrial applications. They are the preferred choice for users who require a cost-effective solution and have relatively low flow requirements. Because of their simple design, single suction pumps are often chosen for systems that need quick installation and occasional use rather than continuous heavy-duty operation.

Double Suction Pumps: Double suction pumps excel in environments where high flow rates are essential, such as large-scale water supply projects, industrial drainage, mining operations, and power stations. These pumps are designed to handle larger volumes of water with minimal wear and tear, making them ideal for long-term, continuous operation in environments where high reliability is required.

Figure | Purity PST single suction pump parts

Cavitation can significantly affect the efficiency and lifespan of a pump, and the ability to resist cavitation differs between single suction and double suction pumps.

Single Suction Pumps: In a single suction pump, the fluid enters the impeller from one side, leading to higher flow velocities. This increases the risk of cavitation, especially in applications involving high speeds or pressure differences. Cavitation occurs when vapor bubbles form in the liquid and then collapse, causing damage to the impeller and reducing the pump's efficiency.

Double Suction Pumps: With fluid entering the impeller from both sides, double suction pumps distribute the flow more evenly, reducing velocity and the likelihood of cavitation. As a result, double suction pumps offer better cavitation resistance, making them suitable for high-flow applications where cavitation is a concern.

At Purity, we offer both single suction and double suction pumps, catering to a wide range of industrial and agricultural needs. All our pumps come with CE certification, ensuring they meet the highest international standards of quality and performance. Our product catalog includes pumps with comprehensive specifications to meet varying customer requirements.

Whether you are looking for a cost-effective, simple solution for smaller projects or a robust, long-lasting pump for heavy-duty applications, Purity has the right product for you.

In summary, single suction pumps are ideal for smaller flow rates, lower budgets, and simpler applications. They are easy to install and maintain, but their limited flow capacity and higher axial thrust can make them less durable in high-demand scenarios.Double suction pumps, while initially more expensive, offer superior flow capacity, better balance, and reduced wear, making them the go-to choice for large-scale industrial projects and long-term use.

At Purity, we strive to provide a comprehensive range of pumps that cater to various needs, ensuring you find the right fit for your specific requirements. Whether you need a single suction pump for a small-scale operation or a double suction pump for a heavy-duty application, we are here to be your trusted supplier.