When selecting a centrifugal pump for your application, understanding the differences between single suction and double suction pumps is crucial. Both types of pumps serve specific purposes and offer distinct advantages depending on the operational requirements. This article explores the design, application scenarios, performance characteristics, and cost considerations of single suction and double suction pumps, helping you make an informed decision.

Figure | Purity centrifugal pump

The primary difference between single suction and double suction pumps lies in the number of suction inlets. Single suction pumps feature one suction inlet, where the liquid enters the impeller from a single side. This design is straightforward, but it generates significant axial force, which can result in higher bearing loads and the need for more robust support structures.

On the other hand, double suction pumps have two suction inlets, with liquid entering the impeller from both sides. This dual-entry design creates a more balanced hydraulic load, effectively reducing axial thrust and enhancing the stability and longevity of the pump. The balanced flow through both sides of the impeller also contributes to smoother operation and increased efficiency.

Due to their design differences, single suction and double suction pumps are suited to different applications:

Single Suction Pumps:These pumps are ideal for low to medium flow applications. Their simple design makes them cost-effective and easy to maintain, making them popular in HVAC systems, industrial processes, and other applications where the flow requirements are moderate. The smaller size and lower complexity of single suction pumps make them a preferred choice for installations with space or budget constraints.

Double Suction Pumps:Designed for high-flow applications, double suction pumps excel in environments where large volumes of liquid need to be transported efficiently and reliably. They are commonly used in water supply systems, circulation systems, mining operations, and large-scale infrastructure projects like municipal waterworks and power stations. The ability to handle higher flow rates with reduced risk of cavitation makes double suction pumps the go-to solution for demanding environments.

Cavitation is a common issue in centrifugal pumps, occurring when the liquid pressure drops below the vapor pressure, leading to the formation of vapor bubbles that can damage the impeller and reduce pump efficiency.

Double suction pumps are inherently more resistant to cavitation due to their symmetrical impeller design. By drawing liquid from both sides of the impeller, the pump maintains a more stable hydraulic balance, reducing the likelihood of cavitation even at high flow rates. In contrast, single suction pumps, especially when operating under high flow conditions, are more susceptible to cavitation because of the uneven flow distribution.

Cost is a significant factor when choosing between single suction and double suction pumps. Single suction pumps are generally more affordable due to their simpler design and fewer components. This makes them an attractive option for projects with limited budgets or where the flow requirements do not justify the higher cost of a double suction pump.

Double suction pumps, while more expensive, offer superior performance in terms of flow capacity, cavitation resistance, and operational stability. The higher upfront cost is often justified by the longer service life and reduced maintenance needs, especially in applications where reliability and efficiency are paramount.

When selecting a pump, it is essential to consider your specific operational needs. If your application requires handling large volumes of liquid with high reliability and minimal risk of cavitation, a double suction pump is likely the better choice. Its robust design and balanced operation make it ideal for demanding environments.

Conversely, if your needs are more modest in terms of flow rate and budget, a single suction pump could be the perfect fit. Its lower cost and simpler construction provide adequate performance for many standard industrial and commercial applications.

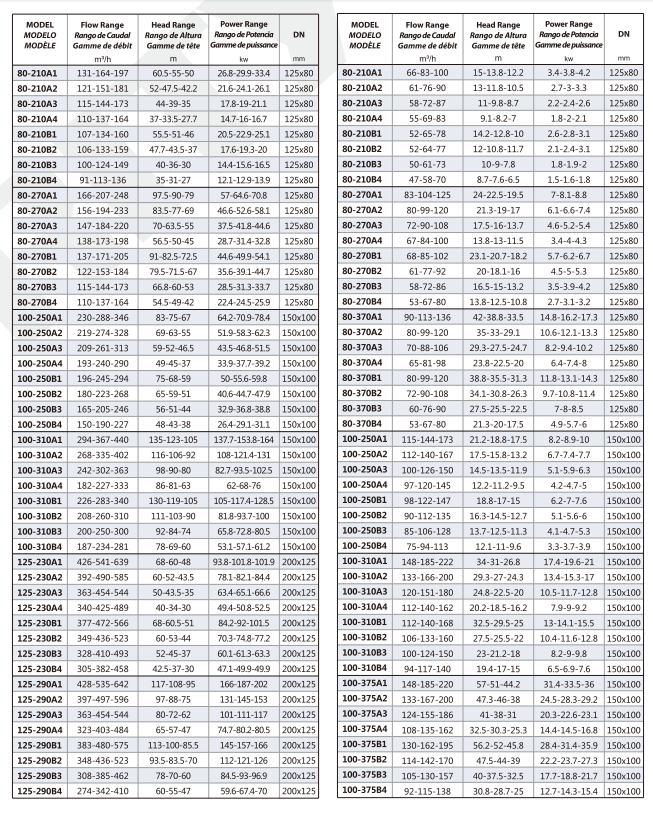

Figure | Purity double suction split case pump PSC

For those seeking high-quality double suction pumps,Purity offers a range of options with unique advantages:

1. Split-Case Design:The split-case construction allows for easy disassembly, inspection, and maintenance without disturbing the alignment of the pump casing or inlet/outlet piping.

2. Superior Suction Performance: The double suction design ensures excellent suction capabilities, even under high flow conditions, maintaining high suction lift.

3. Quiet and Stable Operation:Purity pumps are engineered to operate with minimal noise, ensuring a quiet working environment while maintaining stable performance.

4. Flexible Installation:The pump's drive shaft can be positioned on either side, offering flexibility in installation and operation.

Figure | Purity double suction split case pump PSC parameter

In summary, the choice between single suction and double suction pumps depends on the specific needs of your application. Both types of pumps have their advantages, and Purity offers high-quality options in both categories. Whether you require a cost-effective solution for moderate flow rates or a robust pump capable of handling large volumes with exceptional stability, Purity has a pump that can meet your requirements.