When it comes to fire protection systems, choosing the right fire pump is crucial for ensuring the safety and security of a facility. Electric and diesel fire pumps are the two primary types used in various applications, each with its distinct advantages and disadvantages. Understanding the differences between these pumps can help you make an informed decision based on your specific needs and circumstances.

Figure | Actual Photo Of Purity Diesel Fire Pump

Electric fire pumps are a popular choice for many facilities due to their simplicity and reliability. One of the key advantages of electric fire pumps is their simplicity in operation. These pumps are driven by electric motors that have few moving parts, making them highly reliable and capable of delivering thousands of hours of operation without significant issues. This characteristic translates to low maintenance requirements, as there are fewer components that can wear out or fail over time.

Another significant advantage is the predictability of discharge pressure. Electric fire pumps are typically constant speed pumps, meaning their discharge pressure remains stable and predictable. This stability eliminates the need for pressure safety valves, which are necessary in systems where pressure fluctuations can occur. Furthermore, electric fire pumps can be equipped with explosion-proof motors and controllers, making them suitable for installation in hazardous or explosive environments.

In terms of cost, electric fire pumps are generally the more economical option. They have lower upfront costs, especially when the facility has a reliable electrical power supply. The system’s simplicity also means that installation and operation are less complex, reducing overall costs.

Another limitation of electric fire pumps, particularly larger ones, is the limited number of starts per hour. Typically, these motors can only be started around six times per hour. Frequent starts can lead to the deterioration of the motor’s winding insulation, eventually causing short circuits or damage to the controller’s starting contactor. To address this issue, electric fire pump controllers are required to include a minimum running timer to prevent frequent start/stop cycles that can damage electrical components.

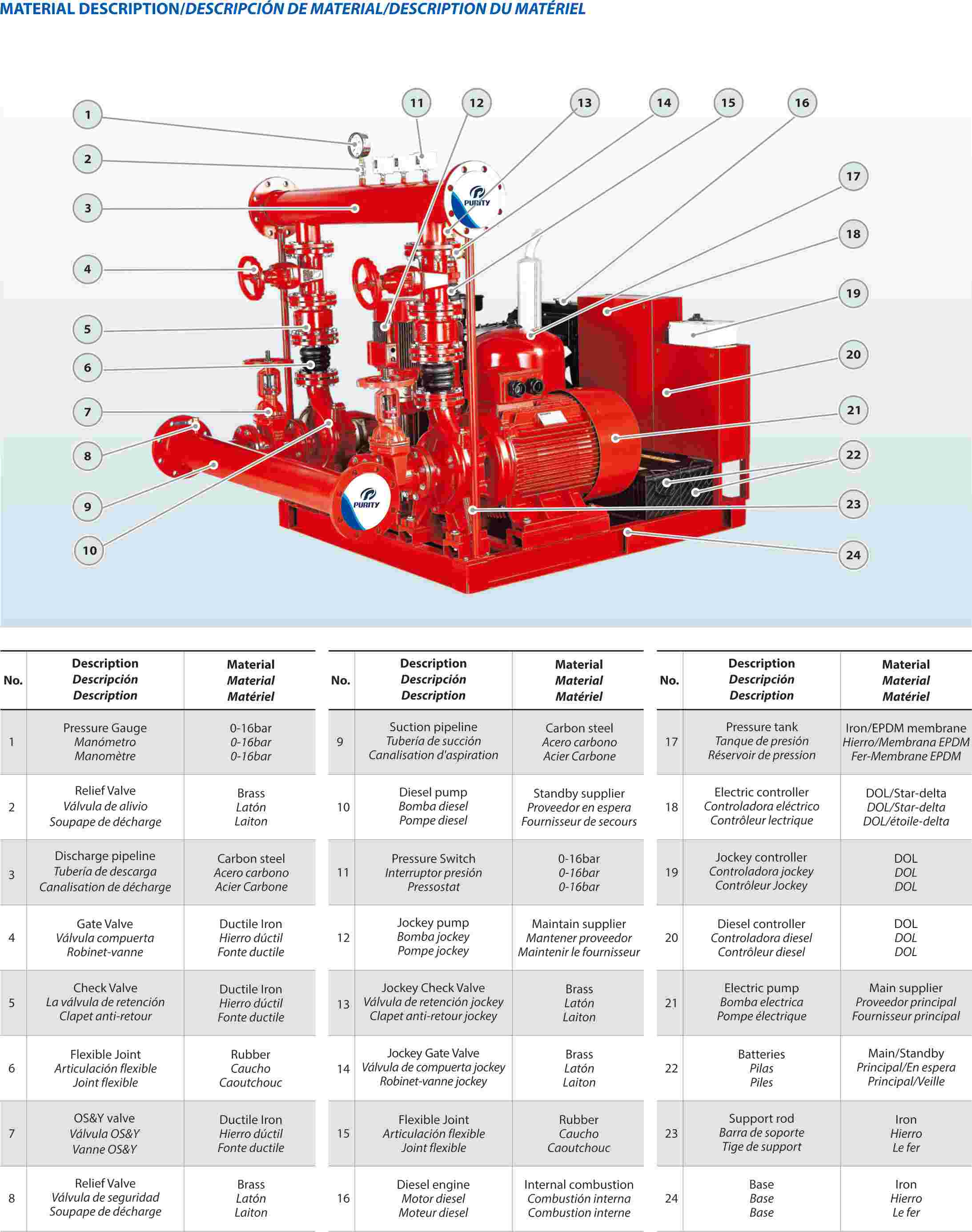

Figure | Purity PEDJ parts

Diesel fire pumps, on the other hand, offer a high degree of self-reliance. Unlike electric pumps, diesel pumps are not dependent on an external power supply for operation, except for control power and battery charging. This independence makes them particularly suitable for areas where the electrical supply is unreliable or prone to interruptions. Even if the power supply is cut off, the engine’s batteries can provide enough cranking power for a few days, ensuring the pump can still start when needed.

The installation cost of diesel fire pumps is also higher due to the additional components required, such as fuel tanks, exhaust systems, ventilation, and cooling lines. These components not only increase the cost but also take up more space in the pump room, which can be a limitation in facilities with restricted space.

Another drawback of diesel fire pumps is the potential for pressure fluctuations. If the engine speed increases, the discharge pressure can rise significantly, potentially damaging the fire water network piping. To prevent this, pressure safety valves must be regularly checked and calibrated. Additionally, diesel fire pumps are not suitable for explosive environments as they cannot be equipped with explosion-proof features.

For those seeking a reliable diesel fire pump, the Purity Diesel Fire Pump System (PEDJ) offers a robust solution. With UL certification and features such as manual/automatic remote control, adjustable control times, and the ability to operate without external power, the PEDJ system is an excellent choice for facilities requiring a dependable fire pump system. Ultimately, selecting the right fire pump is about understanding the unique demands of your facility and choosing a system that meets those needs effectively.