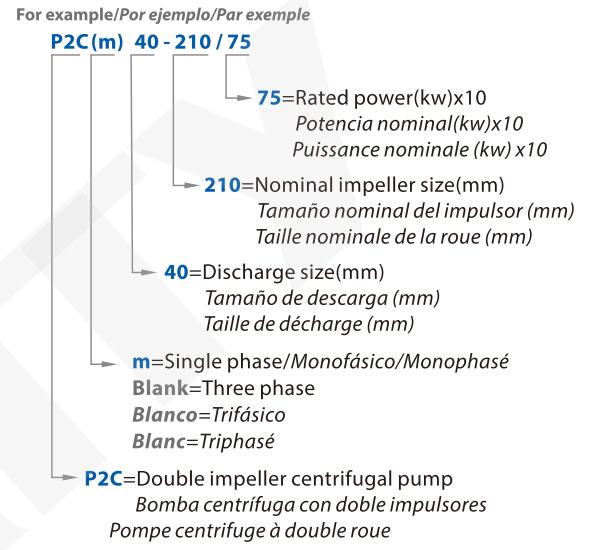

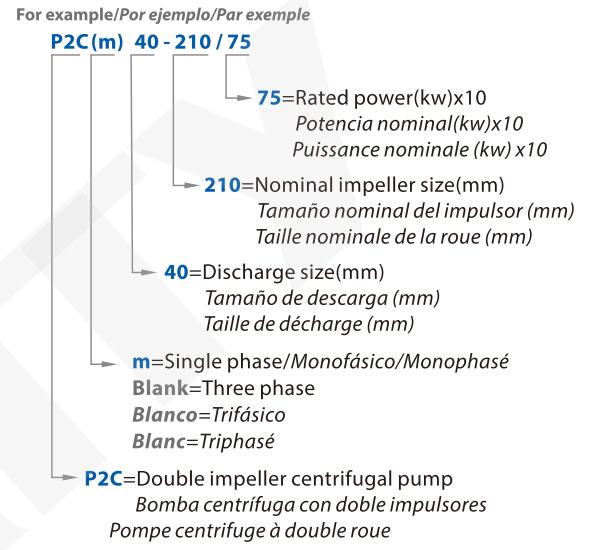

La bomba centrífuga de doble impulsor Purity P2C está diseñada para ofrecer una eficiencia y fiabilidad excepcionales en una amplia gama de aplicaciones industriales y comerciales. Fabricada con impulsores de cobre, garantiza una excelente durabilidad, resistencia a la corrosión y una larga vida útil. Su diseño de doble impulsor permite una mayor altura de bombeo, lo que la convierte en la opción ideal para proyectos que requieren una alta presión de agua y un caudal estable.

Como bomba centrífuga horizontal, el modelo P2C ofrece una instalación sencilla y un funcionamiento estable. El diseño de puerto roscado mejora la comodidad del usuario, permitiendo conexiones de tuberías rápidas y seguras. Además de este modelo, Purity ofrece una línea completa de soluciones de bombeo, que incluye bombas centrífugas monoetapa y nuevas bombas centrífugas industriales, para satisfacer diversas demandas en suministro de agua, climatización (HVAC), protección contra incendios y procesos industriales en general.

Con más de 15 años de experiencia en el sector de bombas industriales, Purity se ha consolidado como un fabricante de confianza comprometido con la innovación y la calidad. Nuestra fábrica ocupa una superficie de 6000 m² y cuenta con el apoyo de un equipo de I+D dedicado que desarrolla continuamente soluciones de bombeo de alto rendimiento. Todas nuestras bombas centrífugas cumplen con certificaciones internacionales como CE, ISO y SASO, lo que garantiza su fiabilidad y compatibilidad con el mercado global.

Purity se dedica a ofrecer productos de primera calidad y se esfuerza por ser su socio predilecto en bombeo industrial. Buscamos activamente distribuidores y agentes globales. Si busca un socio confiable en la industria de las bombas centrífugas, contáctenos hoy mismo para hablar sobre oportunidades de colaboración.

La bomba centrífuga de doble impulsor Purity P2C está diseñada para ofrecer una eficiencia y fiabilidad excepcionales en una amplia gama de aplicaciones industriales y comerciales. Fabricada con impulsores de cobre, garantiza una excelente durabilidad, resistencia a la corrosión y una larga vida útil. Su diseño de doble impulsor permite una mayor altura de bombeo, lo que la convierte en la opción ideal para proyectos que requieren una alta presión de agua y un caudal estable.

Como bomba centrífuga horizontal, el modelo P2C ofrece una instalación sencilla y un funcionamiento estable. El diseño de puerto roscado mejora la comodidad del usuario, permitiendo conexiones de tuberías rápidas y seguras. Además de este modelo, Purity ofrece una línea completa de soluciones de bombeo, que incluye bombas centrífugas monoetapa y nuevas bombas centrífugas industriales, para satisfacer diversas demandas en suministro de agua, climatización (HVAC), protección contra incendios y procesos industriales en general.

Con más de 15 años de experiencia en el sector de bombas industriales, Purity se ha consolidado como un fabricante de confianza comprometido con la innovación y la calidad. Nuestra fábrica ocupa una superficie de 6000 m² y cuenta con el apoyo de un equipo de I+D dedicado que desarrolla continuamente soluciones de bombeo de alto rendimiento. Todas nuestras bombas centrífugas cumplen con certificaciones internacionales como CE, ISO y SASO, lo que garantiza su fiabilidad y compatibilidad con el mercado global.

Purity se dedica a ofrecer productos de primera calidad y se esfuerza por ser su socio predilecto en bombeo industrial. Buscamos activamente distribuidores y agentes globales. Si busca un socio confiable en la industria de las bombas centrífugas, contáctenos hoy mismo para hablar sobre oportunidades de colaboración.