A fire protection pump is one of the most critical components in a building’s fire safety system. Its primary purpose is to increase water pressure and ensure that fire sprinklers, standpipes, and other fire suppression systems receive sufficient water flow during an emergency. While a fire pump does not create its own water supply, it draws water from an existing source—such as a municipal line, water tank, or reservoir—and boosts the pressure so the system can operate effectively.

When a fire sprinkler activates and system pressure drops, the fire pump automatically starts to restore the required pressure. This makes fire protection pumps an essential safeguard for maintaining continuous and reliable water delivery during a fire.

Fire fighting pump systems are typically required when the available water supply cannot deliver adequate pressure to meet fire protection system demands. Common scenarios include:

In certain regions, especially older or remote areas, city water pressure may be insufficient. A fire protection pump ensures that sprinklers and standpipes still receive the necessary pressure during an emergency.

In tall structures, water pressure decreases as it travels upward. A fire water pump compensates for this loss, ensuring upper floors receive adequate flow.

Facilities like warehouses or industrial plants often require higher flow rates and stronger pressure due to their size and fire load.

These applications require stable, high-pressure water delivery, making a fire fighting pump essential.

By boosting pressure to NFPA-required levels, fire protection pumps help ensure that fire suppression systems respond effectively, regardless of building scale or infrastructure limitations.

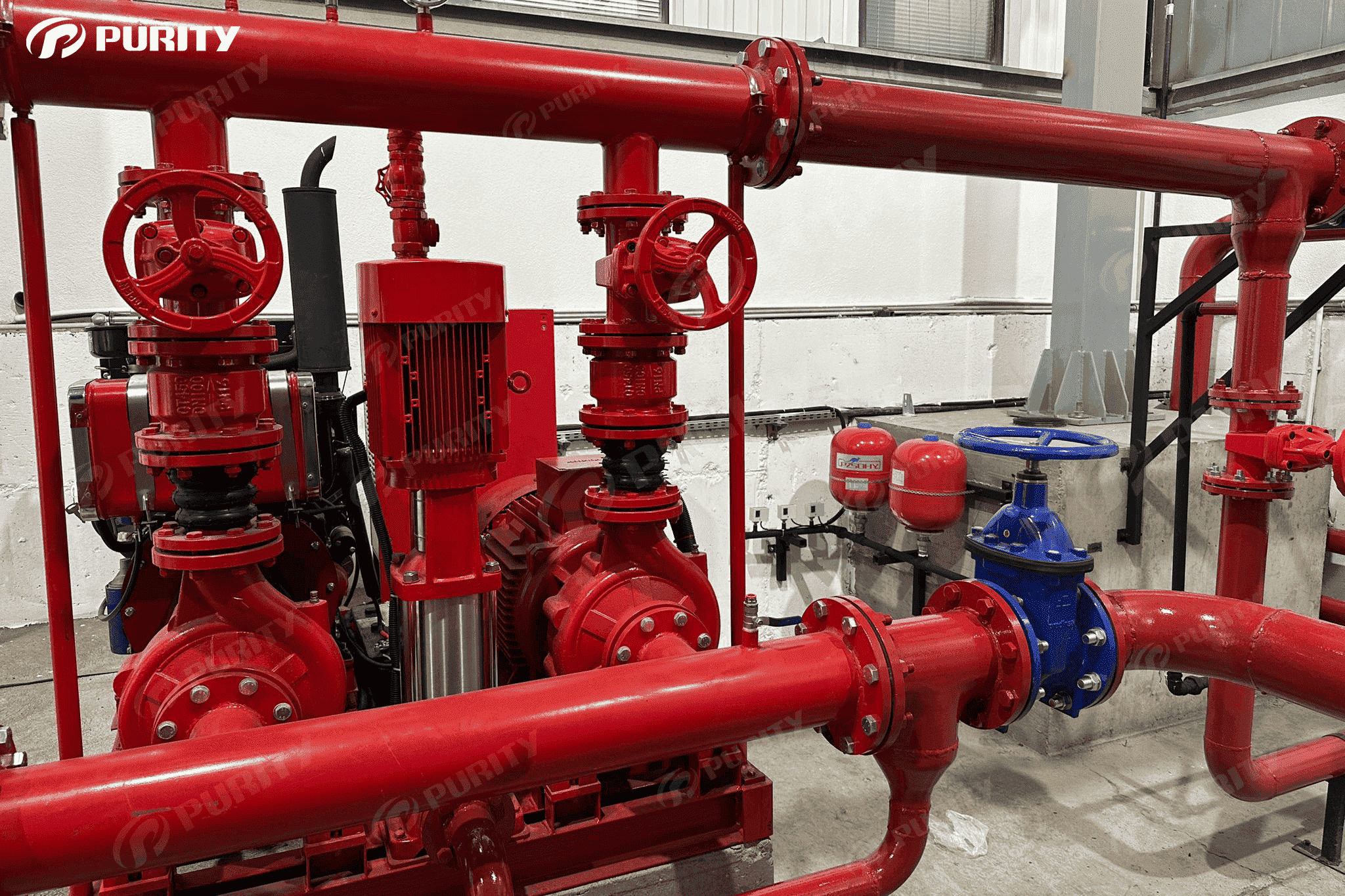

Picture | Purity Fire Fighting Pump in actual application

Fire pump systems vary depending on the power source and building needs. The most common types include:

When choosing a fire protection pump, engineers must consider building height, system water demand, available water supply, electrical conditions, and NFPA design requirements. Selecting the correct fire pump ensures that the fire protection system performs as intended during an emergency.

To be officially recognized as a fire protection pump, equipment must meet strict international standards:

This standard outlines how fire pump systems must be designed, installed, and tested. While NFPA 20 provides guidance, the Authority Having Jurisdiction (AHJ)—such as the local fire marshal or insurance authority—has final approval.

For a fire fighting pump to receive UL Listing or FM Approval, it must pass stringent performance tests, including:

·Rated Duty Point: Defined flow and pressure

·150% Flow Test: Pump must deliver 150% of rated flow while maintaining at least 65% of rated pressure

·Churn Pressure Limit: Must not exceed 140% of rated pressure at zero flow

·Constant Rise to Shutoff (FM): Pressure must rise steadily as flow decreases

·Proper Driver Sizing: The motor or engine must meet maximum horsepower demands

These requirements ensure that fire water pumps can operate reliably under extreme emergency conditions.

Even the best fire protection pumps require continuous maintenance to ensure reliability. NFPA 25 sets clear inspection and testing frequencies:

·Diesel Pumps: Weekly no-flow run; annual full-flow test

·Electric Pumps: Weekly or monthly no-flow test; annual full-flow test

·Pump Room Conditions: Weekly checks for temperature, ventilation, and environmental conditions

·Pressure Relief Valves: Annual inspection; full flow test every 5 years

·Transfer Switches: Monthly inspection; annual simulated power-failure test

·Alarm Devices: Weekly inspection; yearly full test

Other critical measures include routine visual inspections, proper recordkeeping, and immediate corrective action when deficiencies are found.

Modern fire pump systems increasingly incorporate IIoT (Industrial Internet of Things) technology. These smart monitoring platforms enable remote tracking of:

·Pump operating status

·Flow vs. no-flow operation

·Potential system leaks (indicated by jockey pump activity)

·Pump room temperature and environmental risks

·Pressure trends during a fire

This digital insight helps improve system reliability, reduce maintenance downtime, and enhance emergency preparedness.

Purity Pump offers the PEDJ fire pump system with several key advantages:

·Manual/Automatic Dual Control Modes for flexible operation

·Comprehensive Model Range, with selected models meeting international UL certification standards

·Reliable Diesel Backup Operation: Can start via battery power, making it especially valuable in remote areas where electricity is unstable

Purity Pump’s PEDJ series provides dependable performance across diverse applications, supporting high-pressure, high-flow fire protection requirements.

Picture | Purity UL Certificate

Fire protection pumps are essential components that safeguard lives and property by ensuring reliable water pressure during fire emergencies. To guarantee their effectiveness, fire pump systems must be properly designed according to NFPA 20, certified through UL or FM when required, and maintained in compliance with NFPA 25.

Modern IIoT monitoring and high-quality equipment—such as the Purity Pump PEDJ series—further enhance system reliability, ensuring buildings remain protected when it matters most.