When using a centrifugal pump, proper priming is crucial for ensuring optimal performance and preventing damage. Most centrifugal pumps are not self-priming, meaning they require manual priming before operation. Failing to prime the pump correctly can lead to air binding, preventing the pump from moving fluid effectively. This guide will explain why priming is necessary, how to do it correctly, and how self-priming pumps solve this issue.

If you’re looking for centrifugal pump suppliers or searching for a centrifugal pump for sale, it’s essential to understand the priming process to select the best pump for your needs.

Centrifugal pumps operate by transferring rotational energy from the impeller to the fluid. However, if the pump casing contains air instead of liquid, the impeller cannot generate enough pressure to create suction. This leads to air binding, where the pump fails to draw fluid and becomes ineffective.

Proper priming ensures:

✅ The pump starts efficiently without interruptions.

✅ The internal components remain lubricated and cool, preventing overheating.

✅ The pump achieves full operational capacity and optimal efficiency.

The priming process depends on the suction system design. There are two primary configurations:

1.Open the suction isolation valve to allow liquid to enter the pump.

2.Open the air vent valve until all air is expelled, and only liquid escapes.

3. Close the air vent valve to prevent further air entry.

4.Start the pump once the casing is fully filled.

If the pump is positioned above the liquid source, additional steps are required to remove air from the suction pipe.

1.Close the discharge isolation valve to prevent backflow.

2.Open the air vent valve in the pump casing.

3.Use an external liquid source or a foot valve to fill the suction pipe.

6.Start the pump once the system is fully primed.

Unlike standard centrifugal pumps, self-priming pumps are designed to eliminate air automatically and start pumping without manual priming. These pumps mix air with water to create a vacuum, drawing liquid into the pump casing.

However, it’s important to note that self-priming centrifugal pumps cannot run dry. Before startup, ensure that the pump chamber retains enough liquid to facilitate priming.

✅ Advantages of Self-Priming Pumps:

· Eliminates the need for manual priming.

· Can handle applications where the liquid level is below the pump.

· Ideal for situations where frequent stopping and starting are required.

Common self-priming pump types include:

Self-priming water pump – Best for residential and irrigation applications.

Industrial series centrifugal pumps – Designed for demanding applications requiring high efficiency and durability.

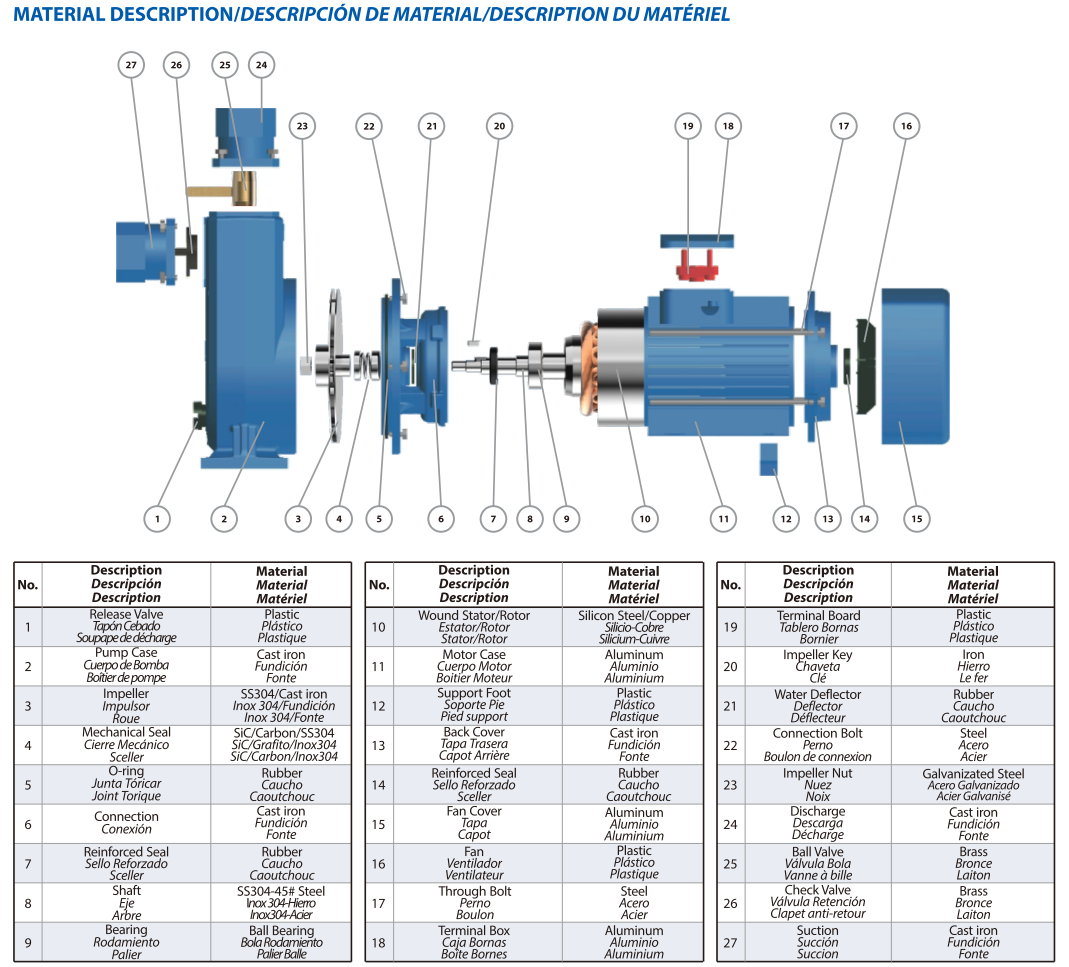

Figure | Purity self-priming pump PXZ parts

Even with proper priming techniques, some challenges may arise:

Air bubbles in long suction pipelines:

· Slow fluid movement can cause air pockets, reducing pump efficiency.

✅ Solution: Ensure the suction line is properly vented and check for leaks.

Bypass system failure:

· If residual liquid in the bypass system creates back pressure, it can prevent air from escaping.

✅ Solution: Make sure the bypass system is fully drained before priming.

Shared exhaust pipe issues:

· Multiple pumps sharing a single exhaust pipe can lead to air backflow.

✅ Solution: Use dedicated venting for each pump.

Suction pipe issues:

· Low liquid levels – If the liquid source is too low, the pump cannot generate enough suction.

· Clogged pipes – Dirt, debris, or a malfunctioning valve can block liquid flow.

· Leaking suction pipes – Even after priming, air leakage can cause operation failure.

✅ Solution: Regularly inspect and maintain suction piping for blockages and leaks.

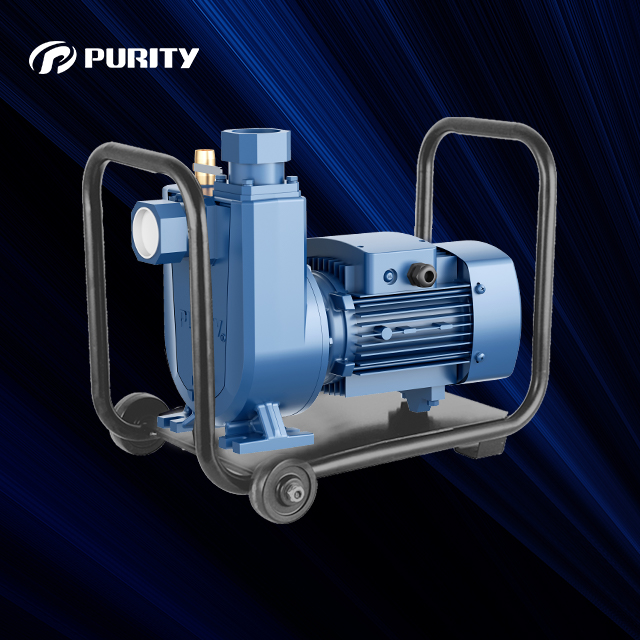

As a leading centrifugal pump supplier with 15 years of industry experience, Purity offers high-performance self-priming centrifugal pumps designed for industrial and commercial applications. Our pumps are sold in over 120 countries, standing out with superior quality and advanced technology.

✅ Premium Motor: Uses a national standard copper-wound motor for low temperature rise and high efficiency.

✅ Enhanced Flow Design: Wider impeller flow path ensures strong sewage-passing capability.

✅ Superior Self-Priming Performance: Larger water chamber and unique return flow hole design for better self-priming ability.

If you're looking for a reliable centrifugal pump for sale, our self-priming pumps are the ideal choice for industrial applications, water supply systems, and waste management.

Figure | Purity self-priming pump PXZ

Whether you choose a standard centrifugal pump with manual priming or a self-priming centrifugal pump, proper priming is essential to prevent operational failures. Understanding different priming methods and troubleshooting common issues can help extend the pump’s lifespan and improve efficiency.

If you’re searching for high-quality industrial series centrifugal pumps, Purity’s self-priming pump series offers unmatched durability, efficiency, and reliability. Contact us today to find the best centrifugal pump for sale for your specific needs!