In the world of fire safety, maintaining consistent water pressure in a fire sprinkler or hydrant system is crucial to ensuring that the system performs as expected during an emergency. Two key components involved in this process are jockey pumps and booster pumps. While both serve to regulate water pressure, they play different roles within a fire pump system. In this article, we’ll break down the differences between jockey pumps and booster pumps, and how they contribute to the efficient operation of fire protection systems.

A jockey pump is a small, high-pressure pump designed to maintain consistent water pressure in a fire protection system when no fire is present. It ensures that the system is ready for activation at a moment’s notice. The jockey pump keeps the water pressure steady in sprinkler or hydrant systems, preventing unnecessary activation of sprinkler heads due to pressure fluctuations.

Jockey pumps are usually multistage centrifugal pumps like the Lowara e-SV or Grundfos CR series. These multistage centrifugal pumps are ideal for applications that require high pressure and consistent flow, ensuring that the sprinkler or hydrant system stays pressurized even when not in use.

· Maintains Pressure: Keeps the fire protection system at the required pressure.

· Prevents Unnecessary Activation: Avoids sprinkler heads opening when no fire is present due to pressure drops.

· Efficient Operation: Works automatically to maintain pressure when minor leaks or small losses occur in the system.

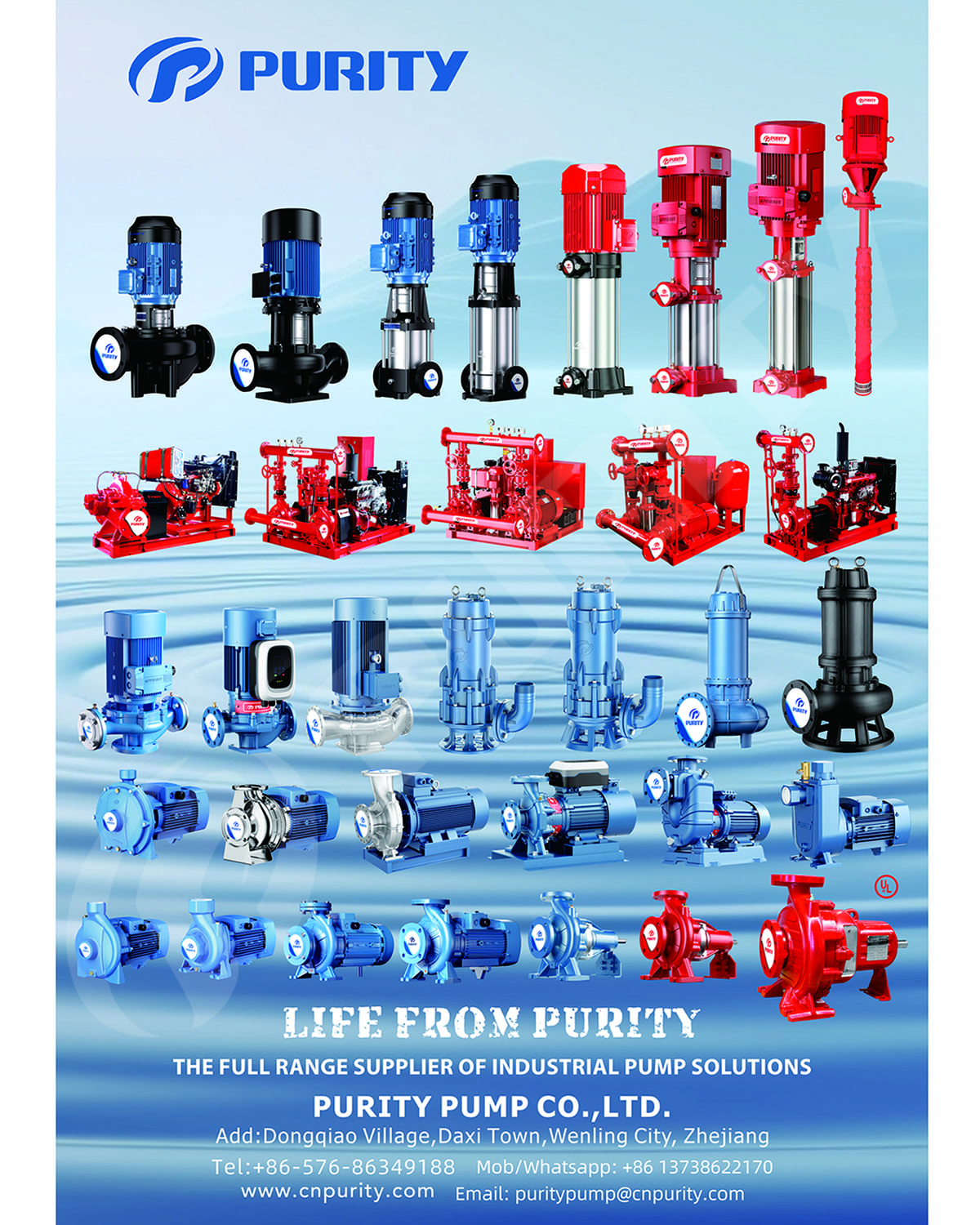

Figure | Purity Multistage Pump & Booster Pump

A booster pump is a larger pump used to increase the water pressure when it falls below the required levels for a fire sprinkler system or hydrant. This is typically needed when the system's water supply is insufficient or the water pressure from the municipal supply or tank is not enough to meet the demands of the system during a fire emergency.

Unlike jockey pumps, booster pumps are activated when the pressure in the system drops below a certain threshold and there is a need for higher flow and pressure to ensure adequate coverage for firefighting.

· Boosts Pressure: Increases water pressure in situations where the system pressure is insufficient.

· Used During Emergencies: Activated when there is a real fire or the system is called into action.

· Higher Capacity: Typically larger than jockey pumps and designed to handle higher flow rates.

While both jockey pumps and booster pumps are used to regulate pressure in a fire protection system, they have distinct functions:

Both jockey pumps and booster pumps often utilize multistage centrifugal pumps due to their efficiency in handling pressure requirements. These pumps work by using multiple impellers (or stages) to increase water pressure progressively as it flows through the pump.

For instance, Lowara e-SV and Grundfos CR pumps are common multistage centrifugal pumps used for jockey pump for fire pump systems. Their design allows for efficient operation and stable performance, which is crucial in fire protection systems. The multistage centrifugal pump design helps ensure that both jockey pumps and booster pumps can handle varying flow rates and pressure levels without compromising on efficiency or reliability.

A specialized application for booster pumps is in preventing false alarms caused by fluctuations in mains water pressure. Some manufacturers, such as Purity Pump, offer compact booster pump sets designed specifically for alarm valve systems. These pumps help maintain stable pressure in systems prone to pressure volatility, ensuring the system works correctly without triggering false alarms.

Booster pumps are also available for domestic and residential fire sprinkler systems. These systems often require pumps designed for smaller scale but still need to meet high standards of pressure and reliability for fire safety.

Purity Pump offers high-quality jockey pumps and booster pumps from trusted brands like Grundfos, Lowara, and Pedrollo. The company also offers customized solutions tailored to your specific needs, including starter boxes and pressure switches. For more demanding applications, Purity Pump has introduced the PVE Jockey pump, which features several performance enhancements:

1. Optimized Fan Structure: Reduced noise by 20% compared to standard models.

2. Full-Range Design: Ensures efficient operation across a wider range of flow rates, preventing motor burnout.

3. Durable Materials: Utilizes 304 stainless steel for the shaft, improving corrosion resistance and longevity.

Figure | Purity Multistage Pump PVE

· Comprehensive Selection: Purity Pump offers a wide range of multistage centrifugal pumps for both jockey pump for fire pump and booster pump applications.

· Customization: From pressure switches to pump starter boxes, Purity Pump tailors solutions to meet specific system requirements.

· Expert Guidance: Purity Pump provides professional advice on pump selection, installation, and maintenance, ensuring optimal performance.

Both jockey pumps and booster pumps are integral components in fire pump systems, each fulfilling a unique role in ensuring that water pressure remains stable and sufficient during emergencies. While jockey pumps maintain pressure in idle systems, booster pumps are activated when pressure drops below the required levels for firefighting operations. With advanced multistage centrifugal pumps like Lowara e-SV and Grundfos CR, you can ensure reliable performance in both types of pumps.

For your fire pump needs, Purity Pump offers a range of high-quality pumps, along with customized solutions to meet your system’s specific requirements. Whether you need a jockey pump to maintain pressure or a booster pump for increased flow during emergencies, Purity Pump provides expert guidance and top-tier products to keep your fire protection system running smoothly.

Contact Purity Pump today to learn more about how we can help you select the right pump for your fire protection system.