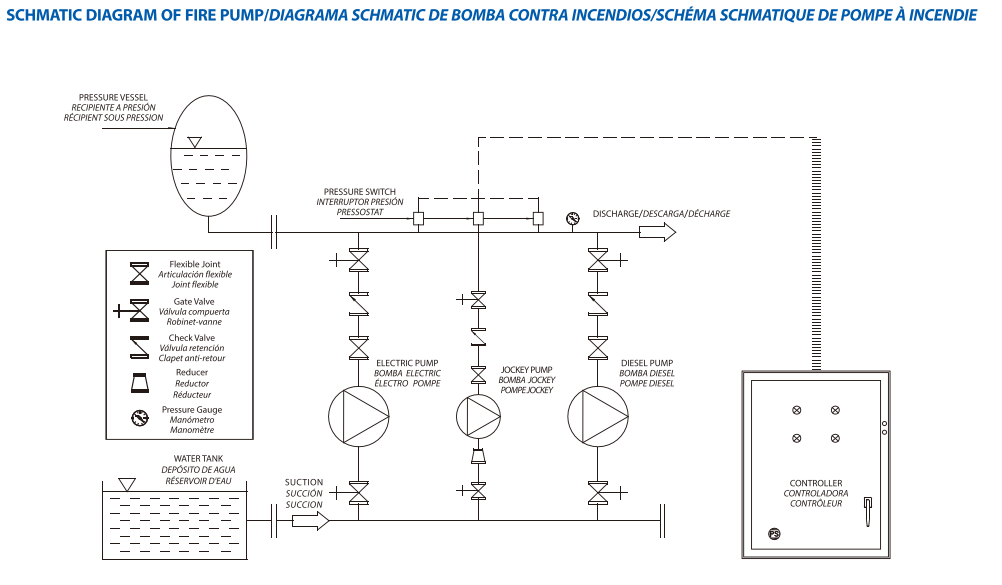

A fire pump is a critical component of a fire protection system, designed to boost water pressure and flow to meet the demands of fire suppression systems like sprinklers, standpipes, foam systems, and water mist systems. Unlike water sources, fire pumps do not generate water but draw it from external supplies such as underground pipelines, water tanks, lakes, or reservoirs. By increasing pressure, they ensure that water is effectively distributed for firefighting purposes, even in challenging scenarios like high-rise buildings or large warehouses. Fire pumps are typically powered by electric motors, diesel engines, or steam turbines and installed in dedicated pump rooms.

Figure | Purity fire pumps

Fire pumps are required when the existing water supply cannot provide sufficient pressure to meet the hydraulic design requirements of a fire protection system. Common scenarios include:

1. Insufficient Water Pressure: High-rise buildings (typically over 400-500 feet) or facilities requiring substantial water flow may need fire pumps to meet demand.

2. Alternative Water Sources: When water is drawn from ground-level storage tanks or underground reservoirs, a fire pump becomes essential to maintain adequate pressure.

3. High Flow Requirements: Certain applications, such as large storage warehouses, require high terminal pressures to deliver the necessary volume of water for effective fire suppression.

Several types of fire pumps are available to suit various needs:

1. Horizontal Split Case Pumps: These are the most common type, known for their durability and adaptability to high-flow requirements. They are also easy to maintain due to accessible components.

2. Vertical Split Case Pumps: Similar to horizontal split case pumps but designed to save space with their vertical orientation, making them ideal for areas prone to flooding.

3. Vertical Inline Pumps: Compact and suitable for limited spaces, these pumps ensure smooth water flow but require removal for maintenance.

4. Vertical Turbine Pumps: Designed for underground or below-water sources such as wells, lakes, or reservoirs.

5. End Suction Pumps: Featuring simple maintenance and minimal strain on piping, these pumps are cost-effective for various applications.

Figure | Purity Diesel Fire Pump

1. Electric Motors: Electric-powered fire pumps are economical and require less maintenance. However, they are vulnerable to power outages, which necessitates the use of backup generators in critical applications.

2. Diesel Engines: Diesel-powered pumps are highly reliable and unaffected by electrical failures. However, they are more expensive and demand regular maintenance.

3. Steam Turbines: Rarely used today, these pumps are reserved for specialized installations.

Proper installation and maintenance are vital for fire pump reliability and performance:

1. Installation: Fire pumps must be designed and installed by professional engineers to comply with local regulations and standards such as those from the NFPA.

2. Routine Inspections:

(1) Visual Checks: Weekly inspections should verify pressure levels, suction and discharge conditions, and ensure valves are open and functional.

(2) Dry Tests: Electric pumps typically require monthly no-flow tests, whereas diesel pumps need weekly testing.

3. Annual Testing: Licensed professionals should perform full-system tests to measure water flow and pressure, comparing results to original specifications to ensure proper functionality.

4. Additional Maintenance: Diesel engines require annual servicing, including fuel filter replacement, battery testing, and fluid checks.

Figure | Purity Diesel Fire Pump Installation

Fire pumps are indispensable in ensuring fire and life safety, particularly in high-rise buildings and large facilities. Choosing the right pump type and conducting regular maintenance ensures the system operates efficiently during emergencies, safeguarding both property and lives.

Purity diesel fire pumps stand out with several unique advantages:

· UL Certification: Ensures compliance with global safety standards.

· Reliable Operation During Power Outages: Powered by diesel engines, they remain operational even during electrical failures.

· Automatic Shutdown Alarms: Enhance safety by alerting users to potential malfunctions.

· Remote Automatic Control: Allows for easy monitoring and control from a distance.

With a wide range of models, Purity diesel fire pumps provide a reliable and effective solution for your fire protection needs. For more information or to discuss your requirements, contact us today!

By investing in high-quality fire pumps and maintaining them regularly, you can ensure a dependable fire protection system that performs effectively when it matters most.