A horizontal centrifugal pump is one of the most common pump types used across various industries due to its flexibility, ease of maintenance, and broad applicability. The horizontal design, where the pump head and motor are mounted on the same plane, provides numerous advantages in terms of installation, performance, and operational efficiency. In this article, we’ll explore the design, functionality, operational benefits, and typical applications of horizontal centrifugal pumps, with a special focus on the unique features of the PST horizontal centrifugal pump by Purity.

Figure | Purity's new horizontal centrifugal pump PST

Horizontal centrifugal pumps are designed with the motor and pump head positioned side by side on a horizontal plane. Depending on the specific application and requirements, the pump can either be close-coupled—where the motor is directly attached to the pump head—or long-coupled, where the motor and pump are connected via a coupling and mounted on a baseplate.

Most horizontal pumps, including Purity's PST series, adhere to the DIN24255/EN733 standards, which ensure that key dimensions, such as inlet and outlet flanges, are standardized, making it easier to replace or interchange parts from different manufacturers. This standardized design is one of the reasons horizontal centrifugal pumps are widely adopted in many industries.

Horizontal pumps offer significant installation flexibility. The inlet and outlet can be positioned in different configurations—top, side, or bottom—depending on the layout of the piping and system design. This allows engineers to optimize the pump's placement and connection with other components in the system.

Installation space is another important factor. Although horizontal centrifugal pumps take up more space on the ground, their horizontal alignment provides greater stability, and the shallower concrete foundations required make them easier to install in larger facilities.

When it comes to fluid handling, horizontal pumps are excellent for pumping clean fluids, fluids with entrained solids, and various process liquids, making them versatile across many industries.

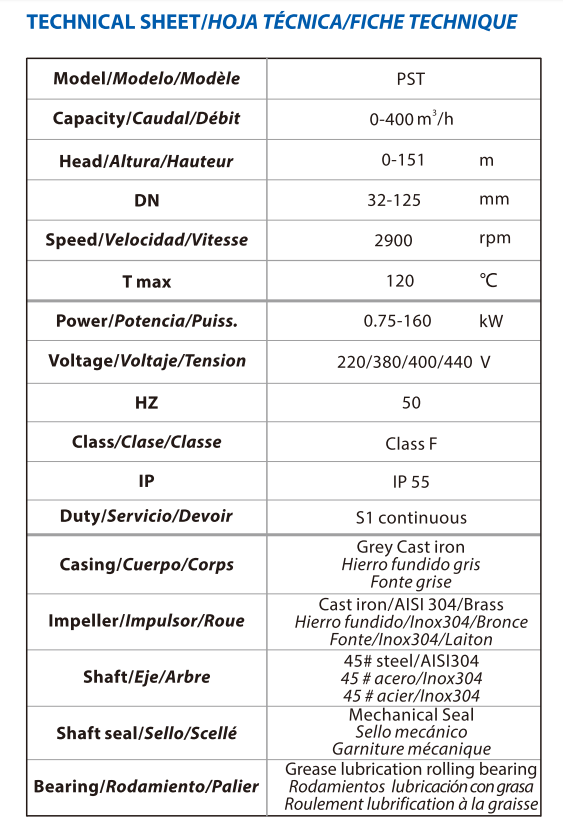

Figure | Purity's new horizontal centrifugal pump PST parameter description

Horizontal centrifugal pumps are widely used in industries such as:

Water Supply and Treatment: Horizontal pumps are commonly found in municipal water systems for transporting and distributing water. They are also extensively used in wastewater treatment plants for pumping sewage and treated water.

Heating, Ventilation, and Air Conditioning (HVAC): These pumps are critical in HVAC systems, helping to circulate water or other fluids through heating and cooling systems to maintain the desired indoor temperatures.

Agriculture: Horizontal centrifugal pumps play a vital role in irrigation systems, ensuring a steady supply of water to crops and farmlands.

Oil and Gas Industry: In this sector, horizontal pumps are used for pumping oil, natural gas, and other fluids in refining, transportation, and storage facilities.

Power Generation: Horizontal centrifugal pumps are commonly used to move fluids within power plants, particularly in cooling systems.

The flexibility of horizontal centrifugal pumps allows them to be deployed in both large-scale industrial operations and smaller setups, making them one of the most reliable choices for engineers looking for a robust, easy-to-maintain solution.

One of the key reasons for choosing horizontal centrifugal pumps is their ease of maintenance. Because the motor and pump head are mounted horizontally, they are easier to access and service. There is no need to lift or remove the motor during routine maintenance, significantly reducing downtime and labor costs.

Additionally, horizontal pumps are better suited for handling heavy loads. This is especially important for applications requiring high-pressure or high-flow pumps, such as multistage pumps. The horizontal alignment helps support the weight of large motors and pump components, reducing strain on the structure and prolonging the pump’s operational life.

Hydraulic simulation design, which ensures smooth performance curves and high pump efficiency.

Equipped with national standard energy-efficient motors, leading to significant energy savings.

A wide range of models, sizes, and power capacities to meet various industrial requirements.

Horizontal centrifugal pumps, with their flexible installation options, self-priming capability, and ease of maintenance, make them the preferred choice for a wide range of industries. Their robust design allows them to handle various fluids, making them suitable for everything from water treatment to industrial processing.

If you're considering a horizontal centrifugal pump for your project, the Purity PST series offers distinct advantages, including advanced hydraulic design, high efficiency, and energy savings. For more information or to determine the best pump for your application, feel free to contact us via phone, email, live chat, or through our online form.