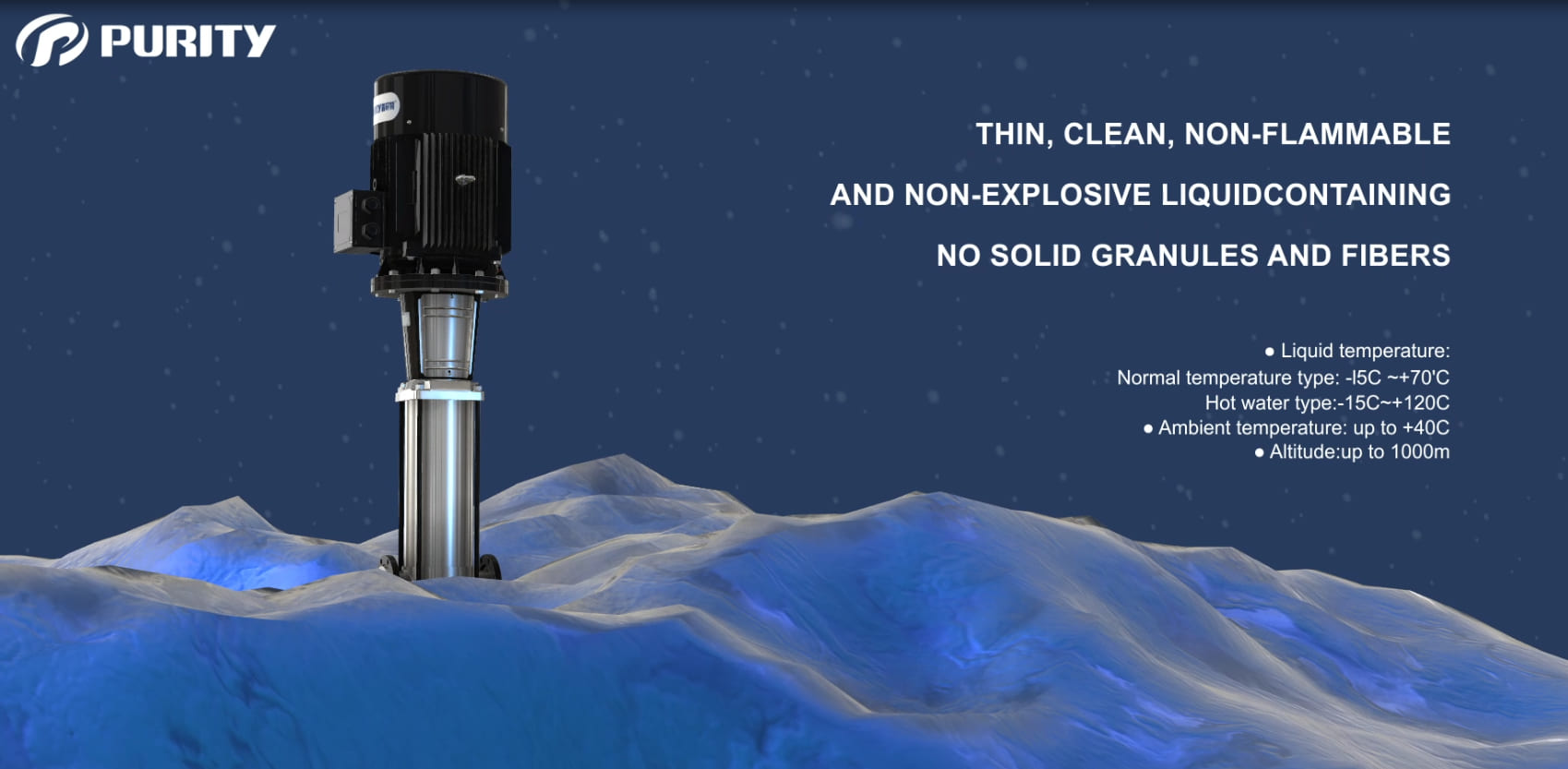

Vertical multistage pumps are a type of centrifugal pump with a vertically oriented shaft. These pumps are designed to handle high-pressure applications and provide a versatile solution for various industrial and commercial needs. Their compact, vertical design makes them suitable for installations where space is limited, and their robust construction ensures reliable performance even under demanding conditions.

The primary distinguishing feature of a vertical multistage pump is its vertical shaft orientation. Unlike horizontal pumps, which require more floor space, vertical pumps are ideal for settings with limited surface area. This space-saving design makes them particularly advantageous in high-rise buildings and other constrained environments.

Vertical multistage pumps operate by coupling with an electric motor. The motor drives the pump shaft directly, rotating at a predefined speed to produce a centrifugal effect. This direct-drive mechanism simplifies the pump's design and enhances its efficiency. The impeller, mounted on the motor shaft, continuously pumps fluid through multiple stages, each increasing the pressure further. This multistage configuration allows the pump to handle high-temperature and high-pressure liquids effectively.

Another notable aspect of vertical multistage pumps is their radial split and overhang design. This structural arrangement enhances the pump's stability and performance, making it suitable for a wide range of applications. Moreover, these pumps typically feature an open impeller design, enabling them to handle even dirty liquids or media containing small solids without clogging or losing efficiency.

Vertical multistage pumps offer several key advantages that make them an excellent choice for various applications:

1. High Chemical and Thermal Resistance: The robust construction of vertical multistage pumps ensures they can withstand harsh chemical environments and high temperatures. This durability makes them ideal for continuous operation in challenging conditions.

2. Ease of Installation and Maintenance: These pumps are designed for easy installation, even without disturbing existing piping. Their modular construction and interchangeable parts simplify maintenance and reduce downtime, ensuring continuous operation with minimal interruptions.

3. Versatile Applications: Vertical multistage pumps are suitable for a wide range of applications. They are often used in high-pressure shower systems, boiler feedwater, and other scenarios where space is limited and reliable performance is crucial.

4. Handling Dirty Liquids: The open impeller design allows vertical multistage pumps to handle liquids containing small solids without clogging. This capability makes them suitable for applications involving dirty or contaminated fluids.

5. Optimized for Clean Water Applications: While they can handle dirty liquids, vertical multistage pumps perform best with clean water. They are particularly effective in applications such as water supply, water treatment, and irrigation systems where clean water is essential.

6. Resilience to Deadhead Conditions: Despite their robustness, it is important to note that vertical multistage pumps are vulnerable to deadhead conditions, where the pump runs without any fluid flow. Proper safeguards and monitoring are necessary to prevent damage in such scenarios.

In conclusion, vertical multistage pumps are a versatile and efficient solution for handling high-pressure and high-temperature liquids in various applications. Their compact design, ease of installation and maintenance, and ability to handle dirty liquids make them an excellent choice for industries ranging from water supply and treatment to industrial processes and irrigation. With their robust construction and reliable performance, vertical multistage pumps are a valuable addition to any pumping system, ensuring continuous operation and high efficiency in even the most demanding environments.