Product Introduction

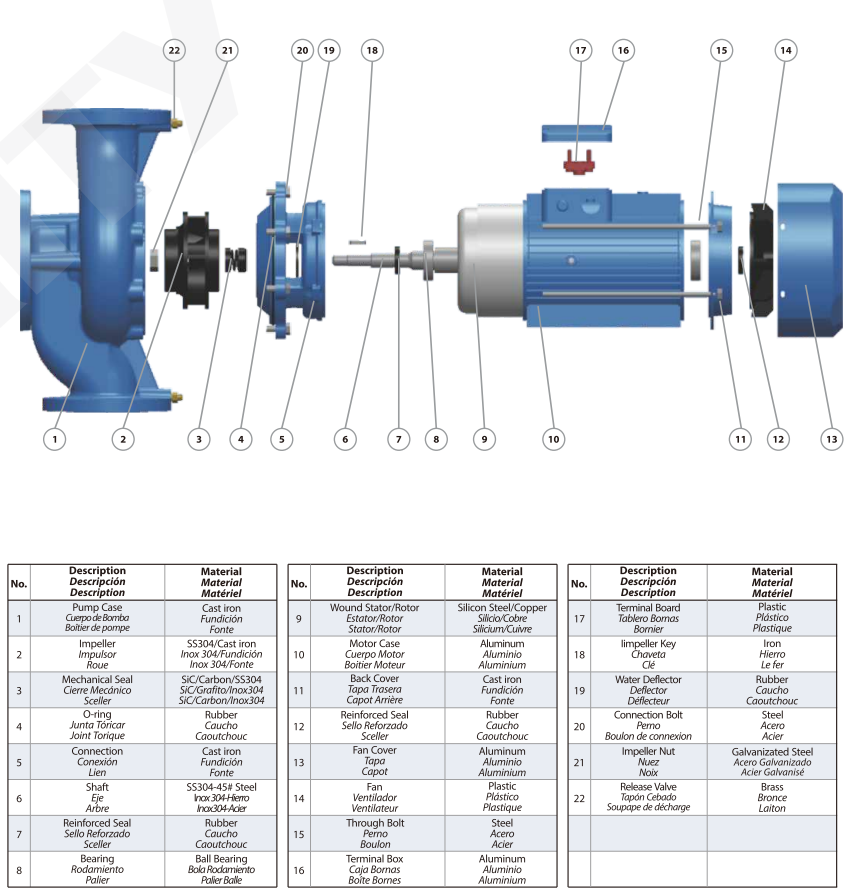

Purity PT vertical centrifugal pump casing and end cover adopt an integrated casting design with a connected lifting structure, significantly improving overall connection strength and shaft concentricity. This solid construction minimizes vibration during operation, enhances hydraulic efficiency, and ensures smoother, more reliable long-term performance.

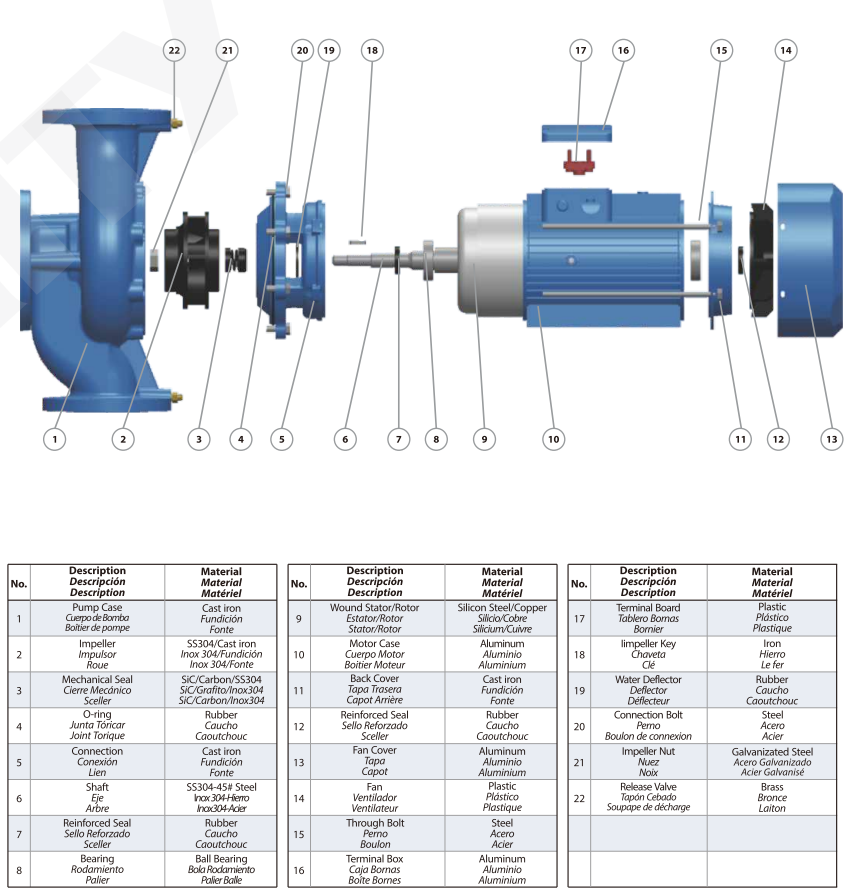

Inside the Purity PT vertical inline centrifugal pump, high-quality core components are carefully selected to guarantee durability and reduced maintenance requirements. Premium NSK bearings provide excellent load capacity and low friction, ensuring quiet and stable operation even under continuous working conditions. The vertical pump centrifugal is equipped with a wear-resistant, high-temperature mechanical seal, making it especially suitable for heating systems and applications involving elevated fluid temperatures. This advanced sealing structure effectively prevents leakage, reduces component wear, and extends the service life of the vertical pump centrifugal. As a result, users benefit from lower downtime and significantly reduced costs associated with dismantling and maintenance over the pump’s lifecycle.

To further enhance efficiency and reliability,Purity PV vertical inline centrifugal pump is driven by a YE3 electric motor. The motor features F-class enameled copper windings, delivering strong insulation performance and excellent heat resistance. With an IP55 protection rating, the motor is well protected against dust and water ingress, allowing the vertical inline centrifugal pump to operate safely in both indoor and demanding industrial environments. This energy-saving motor design not only ensures stable output but also reduces power consumption, helping users achieve long-term energy savings.

Purity has been exported vertical centrifugal pump to overseas vertical centrifugal water pump supplier.Look forward to cooperating with you.