Product Introduction

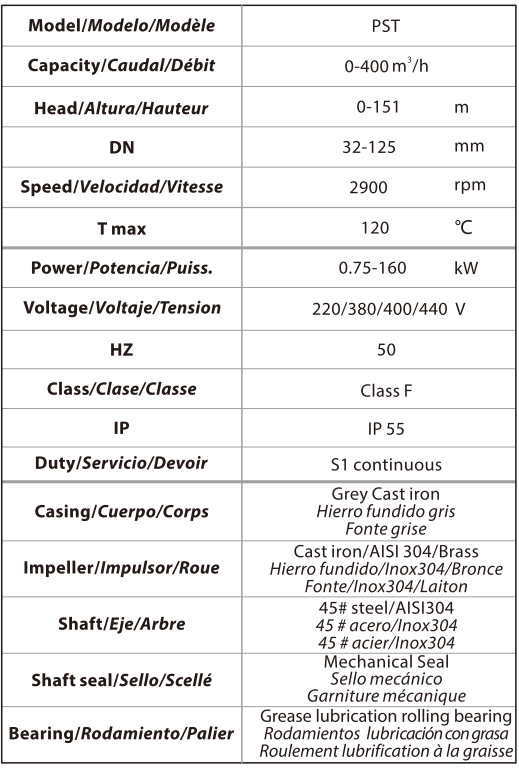

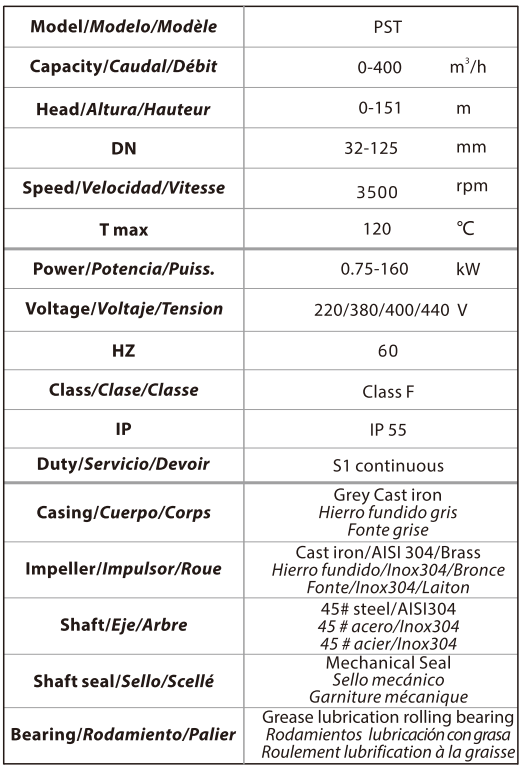

By adopting advanced hydraulic simulation technology during the design stage,Purity PST horizontal single stage centrifugal pump features an optimized hydraulic model that ensures a smooth performance curve and a wide operating range. This refined flow passage design effectively reduces hydraulic losses, minimizes turbulence, and maintains stable flow output even under variable working conditions. As a result, the horizontal centrifugal water pump operates with low vibration, reduced noise, and improved overall efficiency, making it suitable for continuous and long-term operation.

To further enhance energy efficiency and operational reliability,Purity PST horizontal centrifugal water pump is equipped with a YE3 electric motor. The motor uses Class F enameled copper windings, providing excellent thermal resistance and improved insulation performance. This configuration ensures stable power output, reduced energy consumption, and extended service life, even under demanding operating conditions. With a complete range of motor specifications available, the horizontal centrifugal water pump can be flexibly selected to meet diverse flow, head, and application requirements, offering customers greater adaptability for different systems and working environments.

In terms of durability and material selection,Purity PST close coupled centrifugal pump is equipped with a cast iron impeller as standard, ensuring strong mechanical strength and reliable performance in general water transfer applications. For more demanding conditions, such as corrosive media or higher hygiene requirements, bronze or stainless steel impellers can be selected according to specific operating needs. The internal rotating components are supported by high-quality NSK bearings, which significantly reduce friction and mechanical wear, contributing to smooth operation and lower maintenance costs.

Additionally,Purity PST horizontal single stage centrifugal pump adopts a wear-resistant mechanical seal to effectively prevent leakage and ensure safe, stable operation. The pump casing is treated with an anti-corrosion coating, providing excellent resistance to rust and environmental erosion.