Purity PEJ fire pump system offers energy-efficient performance, easy installation, and reliable pressure control—your trusted China fire pump solution for global fire protection projects.

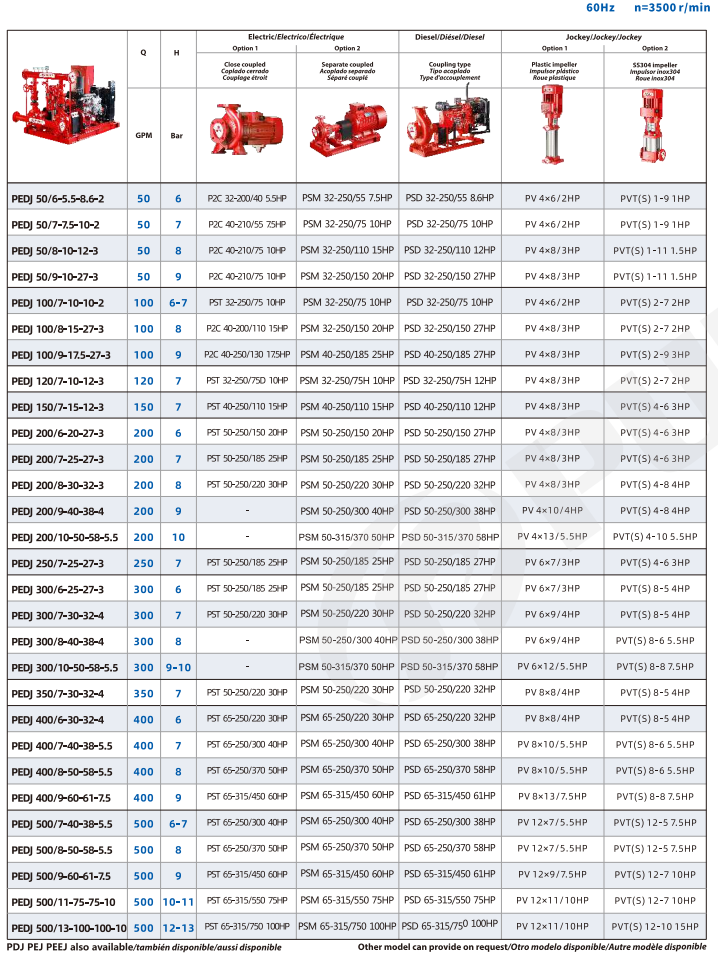

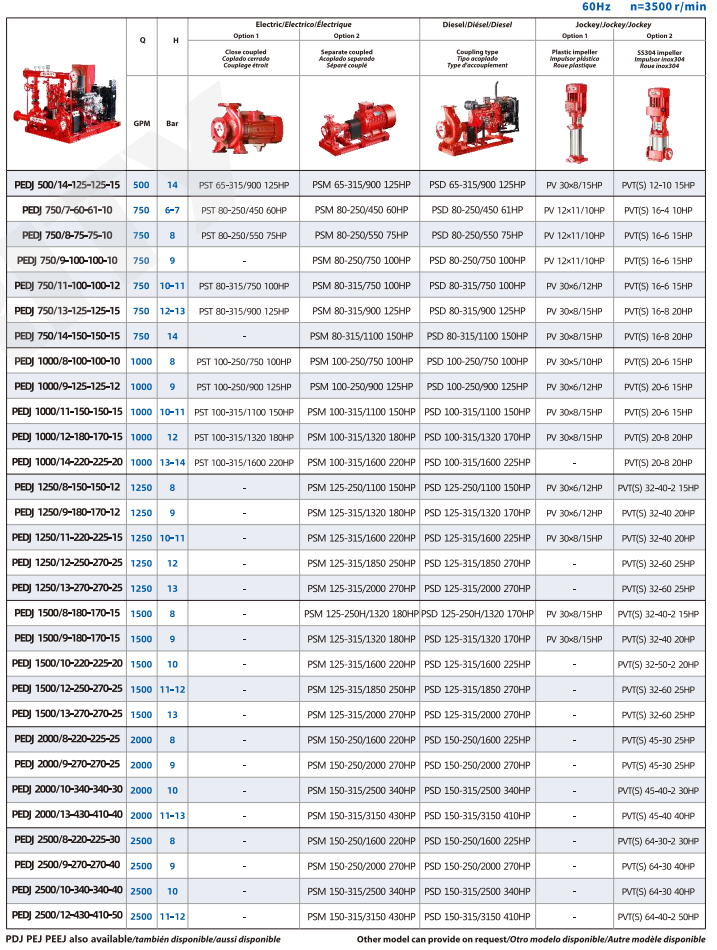

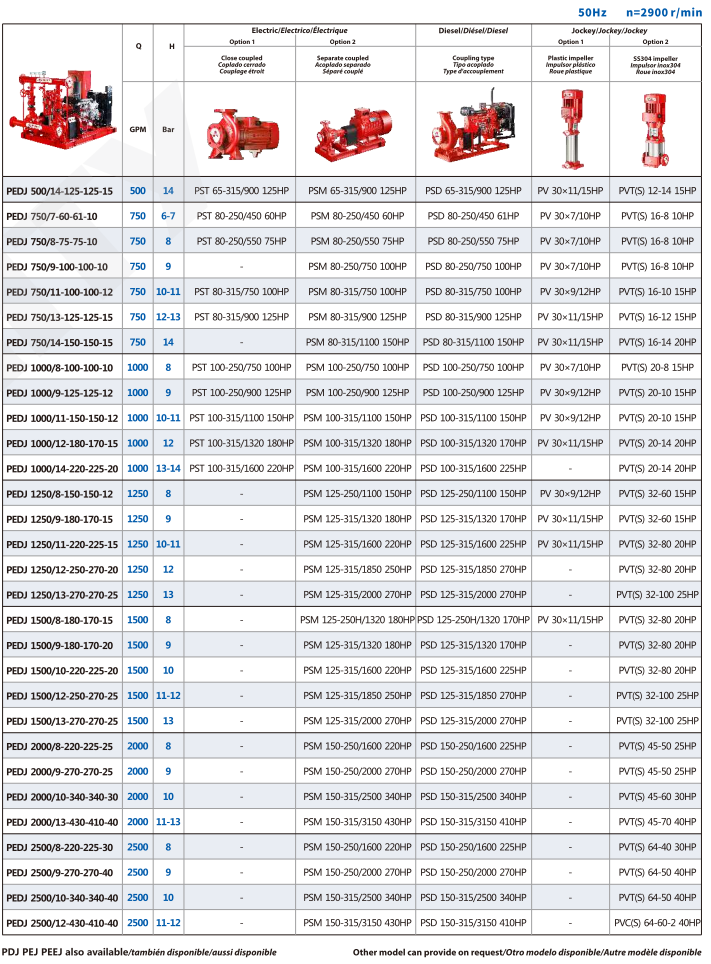

The Purity PEJ fire pump system is designed for customers who need a high-quality and easy-to-use solution from a trusted fire pump factory in China. Built with a simplified operating design, the PEJ unit requires no additional assembly, allowing users to install and start the system quickly—ideal for urgent projects and emergency applications.

To meet modern efficiency demands, the PEJ system combines a low-power jockey pump with a high-power electric fire pump, delivering outstanding energy savings while maintaining stable pressure. This intelligent configuration significantly reduces electricity consumption, making the PEJ an excellent choice for developers, contractors, and distributors looking to buy fire fighting pumps that deliver both performance and value.

Engineered with flexible structures and multiple configurations, the Purity PEJ fire pump system complies with Chinese specifications and can be customized for various fire suppression system pumps applications, including commercial buildings, industrial facilities, high-rise complexes, and emergency water supply projects. Its adaptability ensures reliable performance across different installation environments.

With 15 years of experience in the fire pump industry, Purity has grown into a leading fire pump China manufacturer, exporting products to over 130 countries. Our factory covers 60,000 square meters and is supported by a professional R&D team dedicated to innovation, safety, and long-term reliability. As an experienced emergency fire pump factory, we are committed to delivering internationally trusted quality.

Purity is now seeking global distributors and partners. If you are looking for durable and efficient fire suppression system pumps, or if you want to buy a high-performance fire pump directly from a reliable China manufacturer, contact us today. We look forward to becoming your preferred fire pump supplier worldwide.

The Purity PEJ fire pump system is designed for customers who need a high-quality and easy-to-use solution from a trusted fire pump factory in China. Built with a simplified operating design, the PEJ unit requires no additional assembly, allowing users to install and start the system quickly—ideal for urgent projects and emergency applications.

To meet modern efficiency demands, the PEJ system combines a low-power jockey pump with a high-power electric fire pump, delivering outstanding energy savings while maintaining stable pressure. This intelligent configuration significantly reduces electricity consumption, making the PEJ an excellent choice for developers, contractors, and distributors looking to buy fire fighting pumps that deliver both performance and value.

Engineered with flexible structures and multiple configurations, the Purity PEJ fire pump system complies with Chinese specifications and can be customized for various fire suppression system pumps applications, including commercial buildings, industrial facilities, high-rise complexes, and emergency water supply projects. Its adaptability ensures reliable performance across different installation environments.

With 15 years of experience in the fire pump industry, Purity has grown into a leading fire pump China manufacturer, exporting products to over 130 countries. Our factory covers 60,000 square meters and is supported by a professional R&D team dedicated to innovation, safety, and long-term reliability. As an experienced emergency fire pump factory, we are committed to delivering internationally trusted quality.

Purity is now seeking global distributors and partners. If you are looking for durable and efficient fire suppression system pumps, or if you want to buy a high-performance fire pump directly from a reliable China manufacturer, contact us today. We look forward to becoming your preferred fire pump supplier worldwide.