Product Introduction

Purity PZ stainless steel centrifugal pump is designed using advanced hydraulic simulation technology, ensuring a smooth performance curve and a wide flow range. This precise hydraulic design allows the pump to deliver stable operation and high efficiency under various working conditions.

Equipped with a high-efficiency motor,Purity PZ industrial stainless steel centrifugal pumps provide excellent energy-saving performance while maintaining powerful output. The motor features IP55 protection and F-class insulation, ensuring safe and reliable operation even in demanding environments. With a complete range of models available, Purity PZ stainless steel centrifugal pump can be customized to meet different flow and pressure requirements, offering flexible solutions for diverse customer needs.

All wetted parts are made of high-quality stainless steel, ensuring cleanliness, and environmental protection.Purity PZ stainless steel centrifugal pump is equipped with premium NSK bearings and a durable mechanical seal, which significantly enhance its wear resistance and reduce maintenance costs over long-term operation.

With its combination of superior hydraulic performance, durable construction, and energy-efficient motor, Purity PZ stainless steel centrifugal pump represents an ideal choice for clean water transfer, industrial circulation, and pressure boosting systems.

Purity as one of stainless steel centrifugal pump manufacturers in China,stainless steel centrifugal pump for sale is high quality.Wellcome to inquiry Purity Pump!

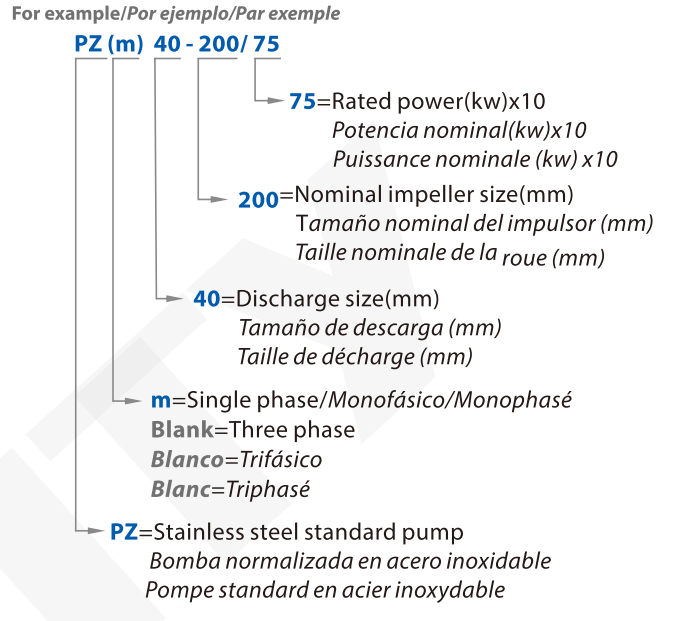

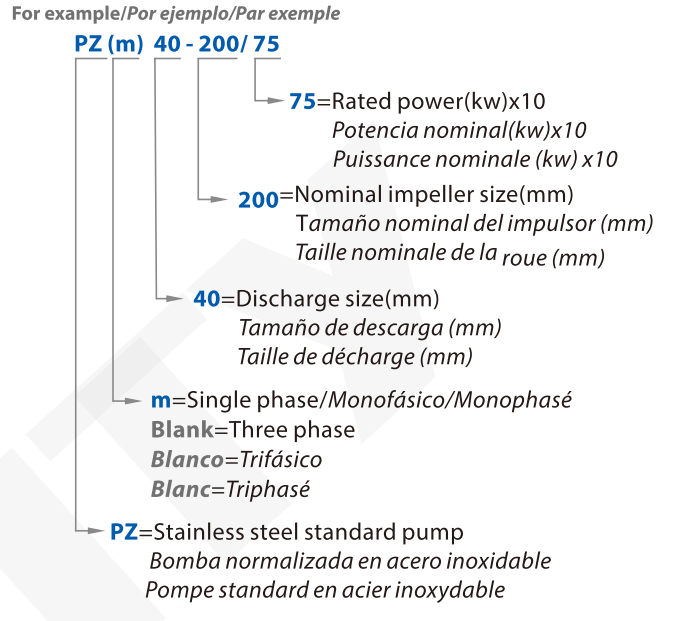

Model Description

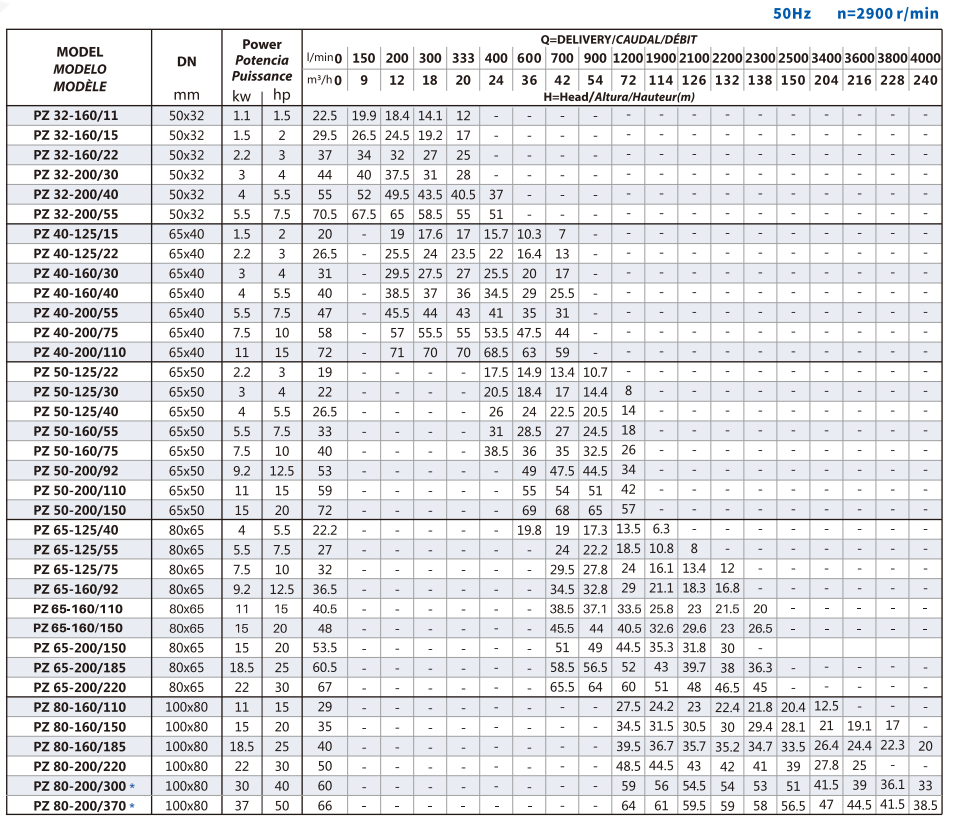

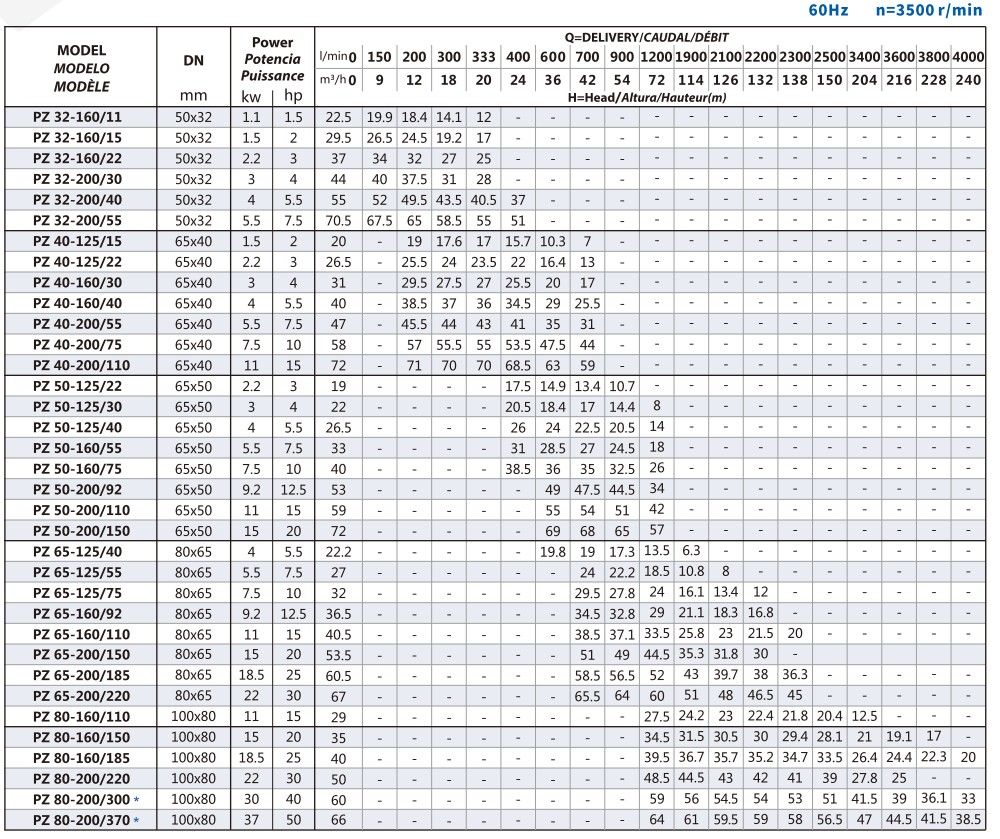

Product Parameters