Product Introduction

Purity PGW-G electric driven centrifugal pump body adopts an integrated casting design that seamlessly connects the main housing with the end cover lifting structure. This robust construction significantly enhances connection strength and concentricity, reducing mechanical loss during operation. As a result, PGW-G single stage centrifugal pumps operate with greater stability and efficiency while achieving an extended overall service life, even under continuous or heavy-duty conditions.

To ensure strong and consistent power output,Purity PGW-G industrial centrifugal water pump is equipped with a premium YE3 motor. The motor stator is manufactured using high-performance non-oriented cold-rolled steel strips, which help reduce magnetic loss and improve energy conversion efficiency. In addition, the motor uses pure copper windings known for excellent conductivity, low temperature rise, and superior durability. This advanced motor configuration enables the monoblock pump and centrifugal pump to deliver outstanding operational efficiency, lower energy consumption, and dependable long-term performance.

Noise control is another key advantage of PGW-G industrial centrifugal water pump. Thanks to an upgraded impeller and fan design, the overall noise level is reduced by up to 10% compared with conventional industrial pumps. The redesigned fan blades optimize airflow for faster and more effective heat dissipation, ensuring the motor remains cool during continuous operation. This improvement not only minimizes acoustic disturbances in industrial environments but also enhances motor lifespan by maintaining optimal temperature conditions.

Purity specializes in manufacturing industrial centrifugal water pump and booster centrifugal pump, with high product standards and quality. Welcome to inquiry!

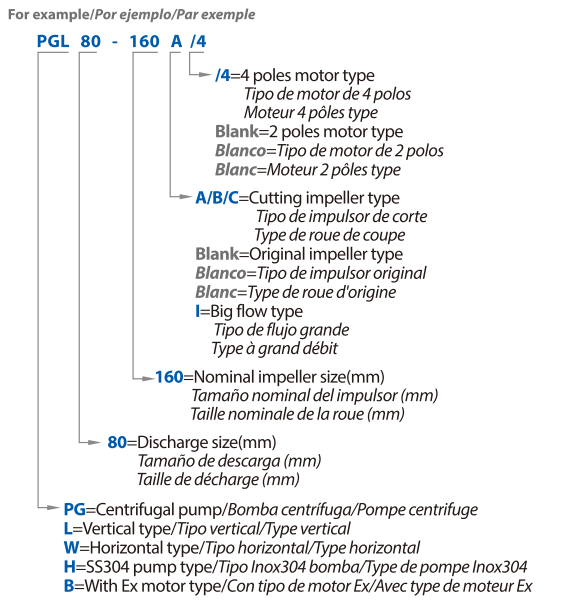

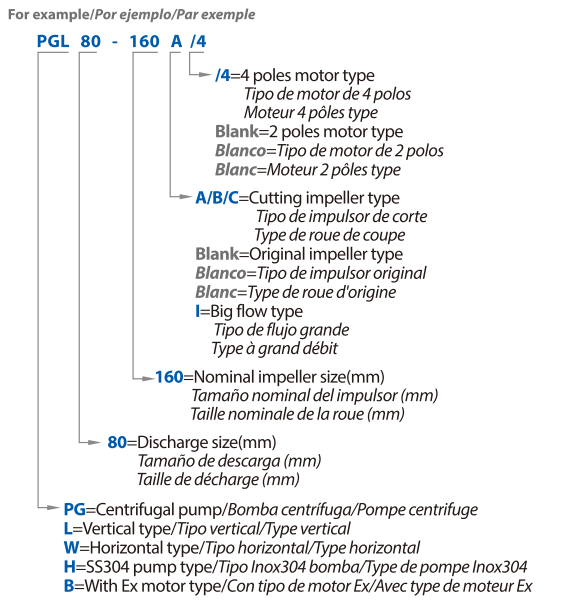

Model Description

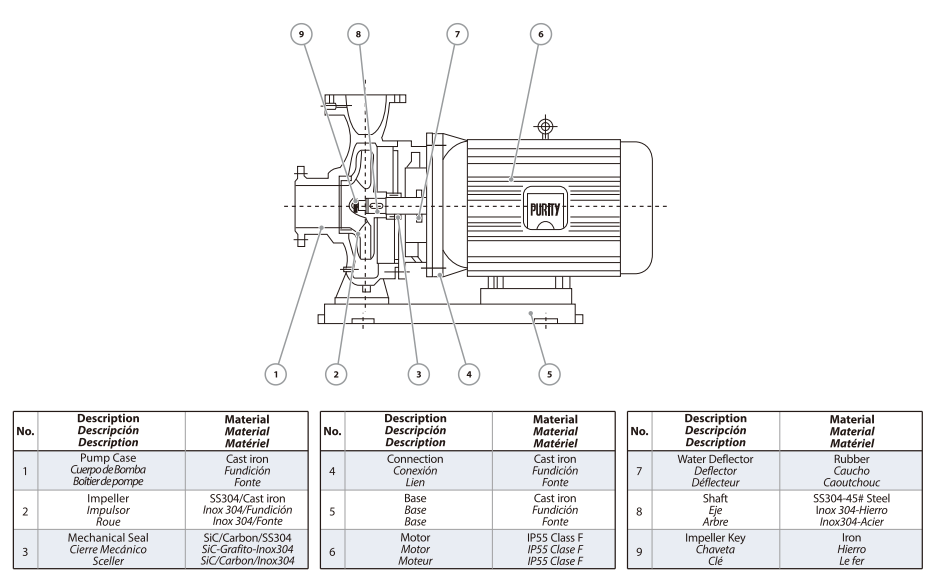

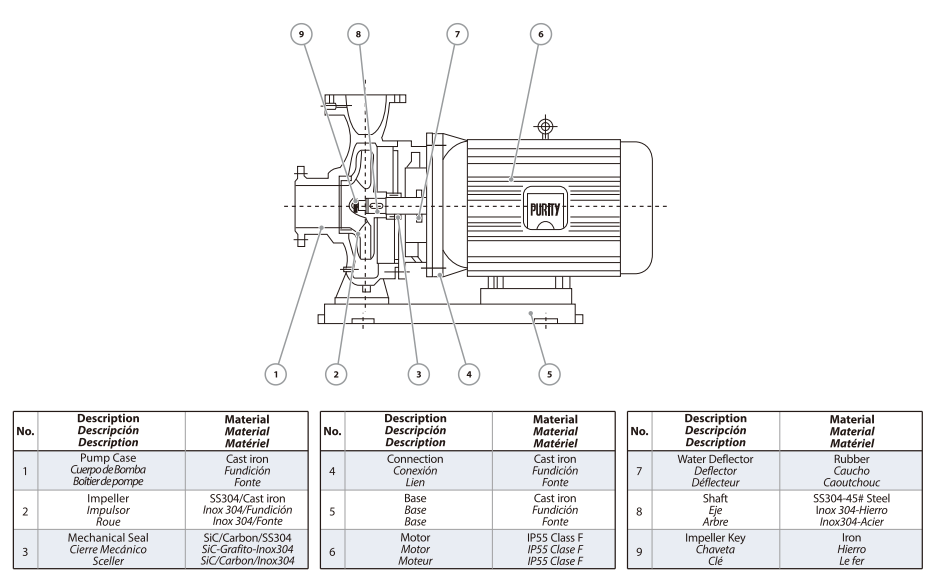

Product Components

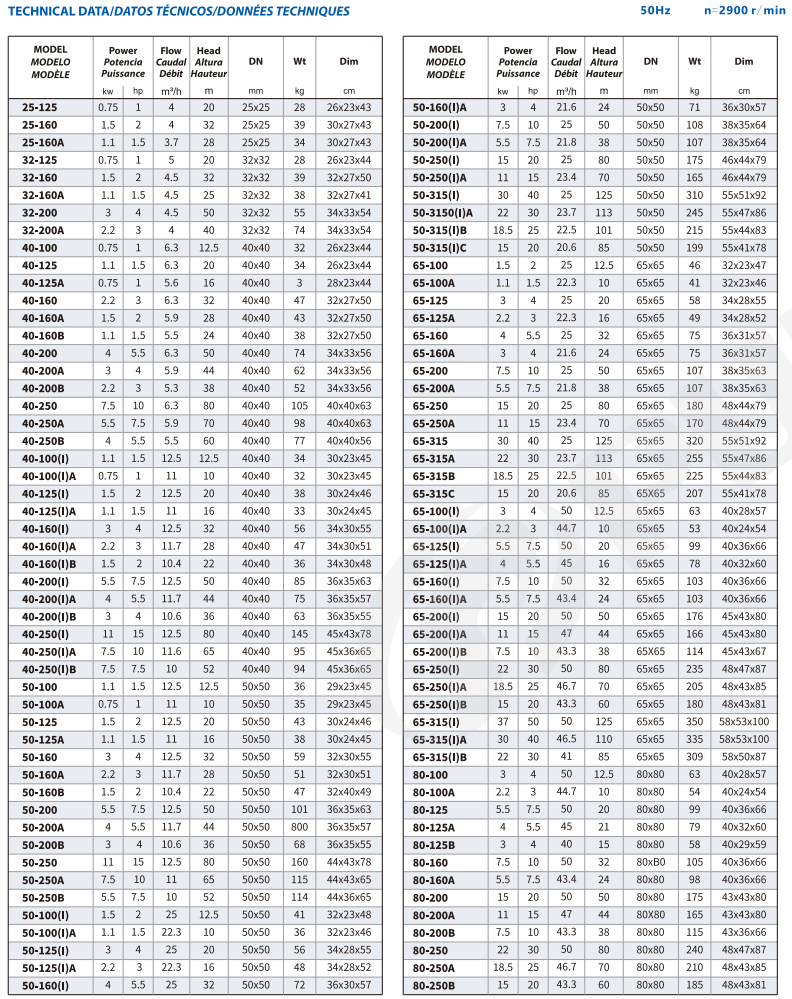

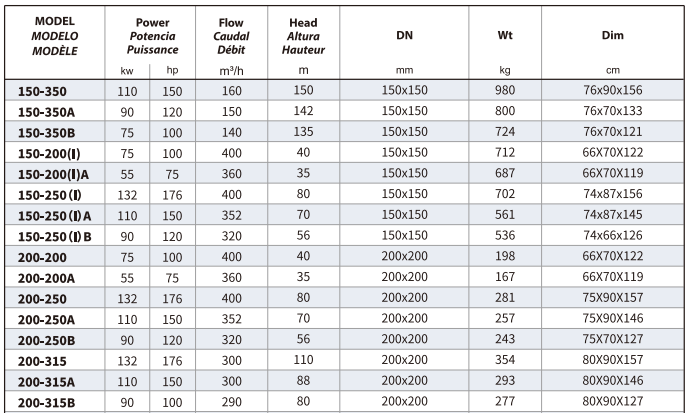

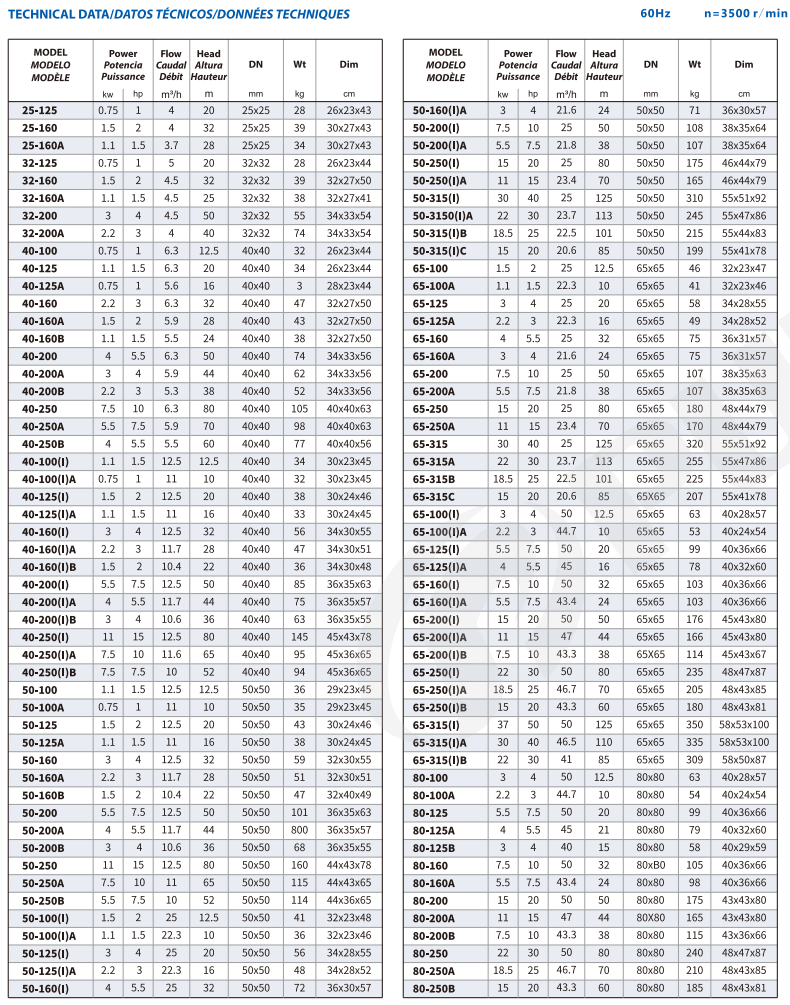

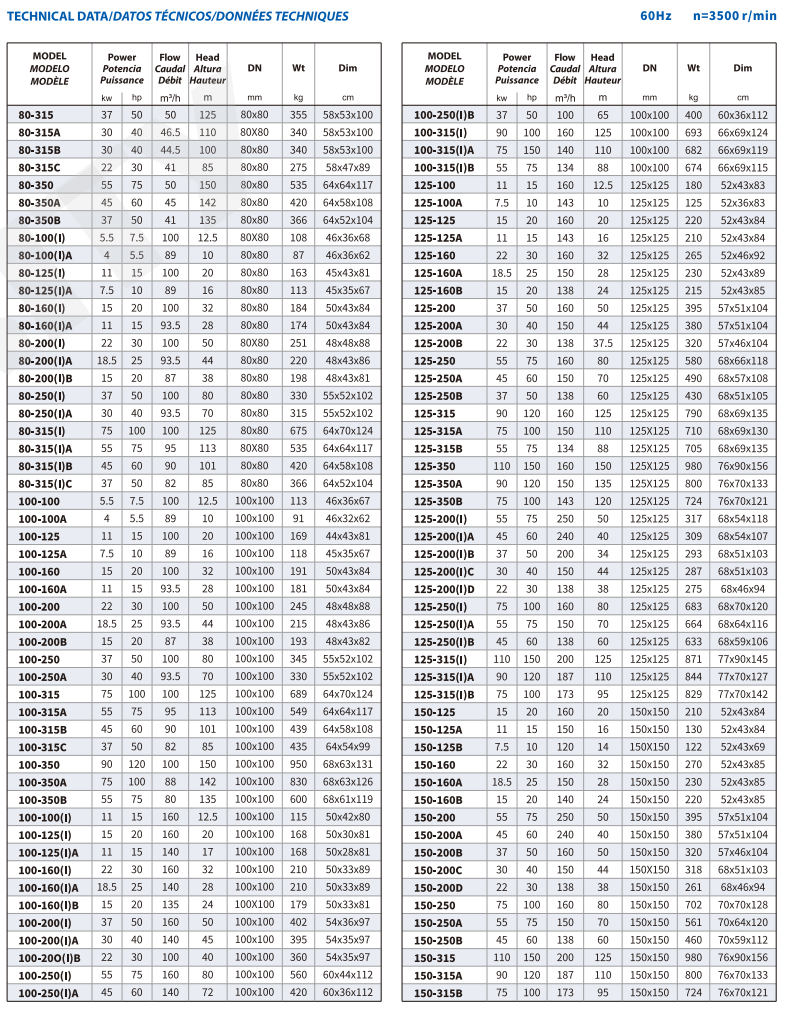

Product Parameters