Product Introduction

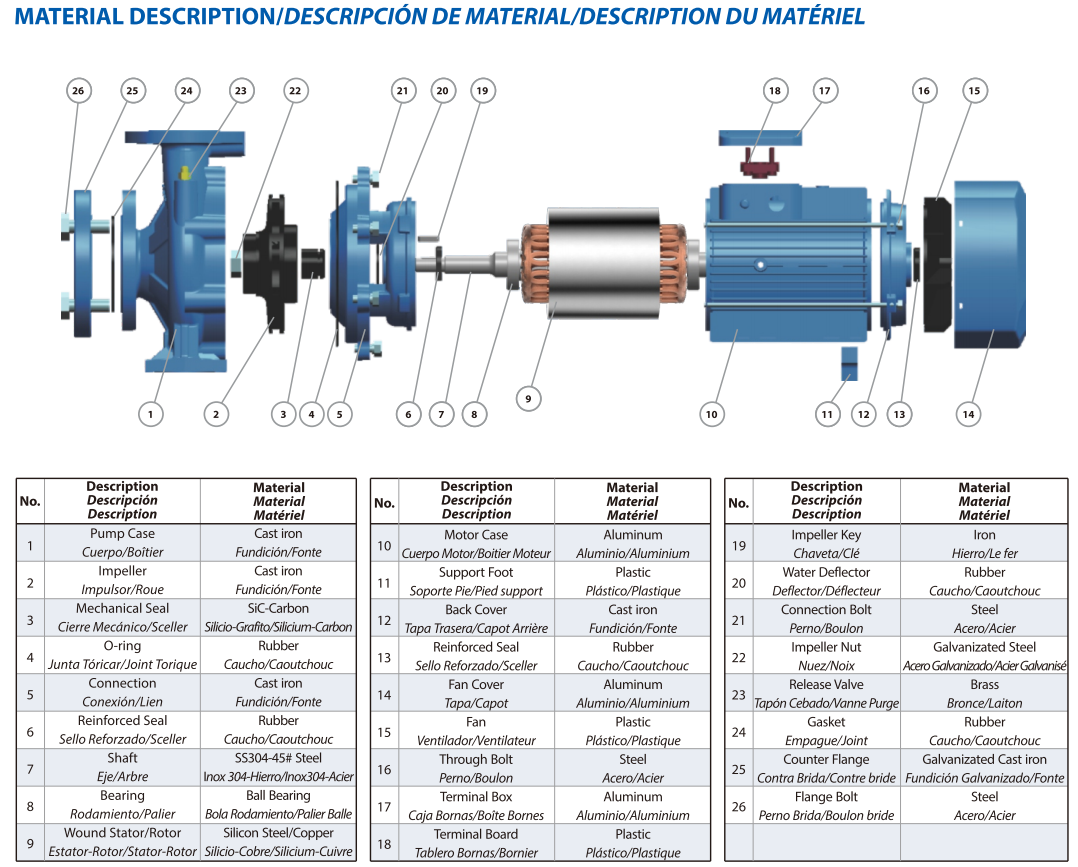

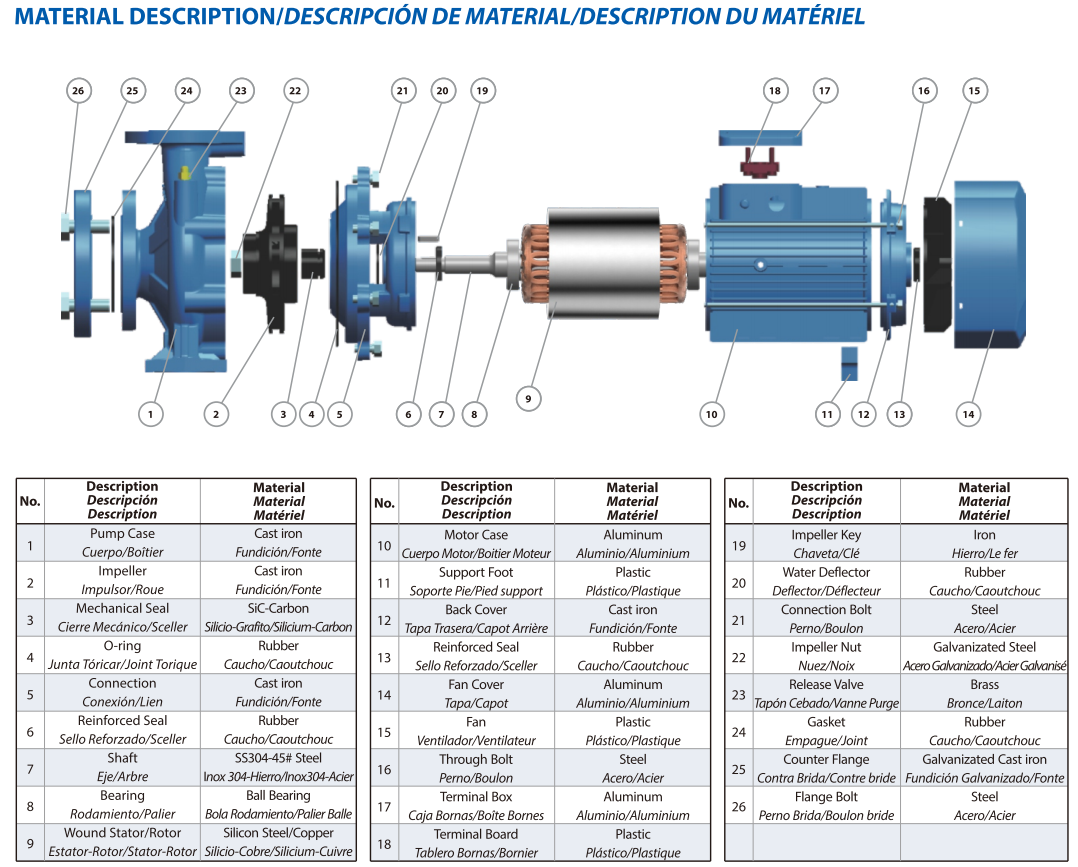

One of the key design advantages of Purity PW centrifugal irrigation pump is its integrally cast connection and end-cover lifting structure. The pump casing, connection parts, and end cover are manufactured using one-piece casting technology, which significantly enhances overall structural strength and rigidity. This integrated design improves shaft alignment and concentricity, effectively reducing vibration and mechanical losses during operation.

The Purity PW centrifugal water pump is equipped with a YE3 energy-saving motor, designed to meet modern energy efficiency standards. The motor uses Class F enameled copper wire with sufficient material content, ensuring excellent thermal resistance and stable electrical performance. This configuration not only improves motor efficiency but also enhances reliability under long-term operation. Lower energy consumption helps reduce operating costs while maintaining strong and stable output, making the centrifugal water pump an economical choice for various fluid transfer systems.

In addition to its performance advantages, this Purity PW centrifugal irrigation pump features a compact and lightweight overall design. The optimized structure minimizes installation space requirements, allowing easy integration into pipeline systems, equipment skids, or confined mechanical rooms. Its small footprint and reduced weight also make disassembly, inspection, and routine maintenance more convenient, significantly lowering labor intensity and downtime. Whether used for water supply, industrial circulation, or general fluid transport, the pump can be installed and serviced with ease.

Purity PW centrifugal pump for sale has been exported to centrifugal pump suppliers multiple countries.Welcome to inquiry Purity centrifugal pumps!