Purity Pump Co., Ltd. is a specialized manufacturer and supplier of high-quality

industrial pumps, exporting to global market in competitive prices. We provide

various reliable pumps for projects. Our main products are centrifugal pumps, fire

pumps and system, industrial pumps and agricultural pumps.

Our products and services have been deployed in more than 55 countries.

And we supply water pumps for many large projects like National Olympic Stadium.

We also supply centrifugal and fire pumps to some well-known pump companies all

over the world.

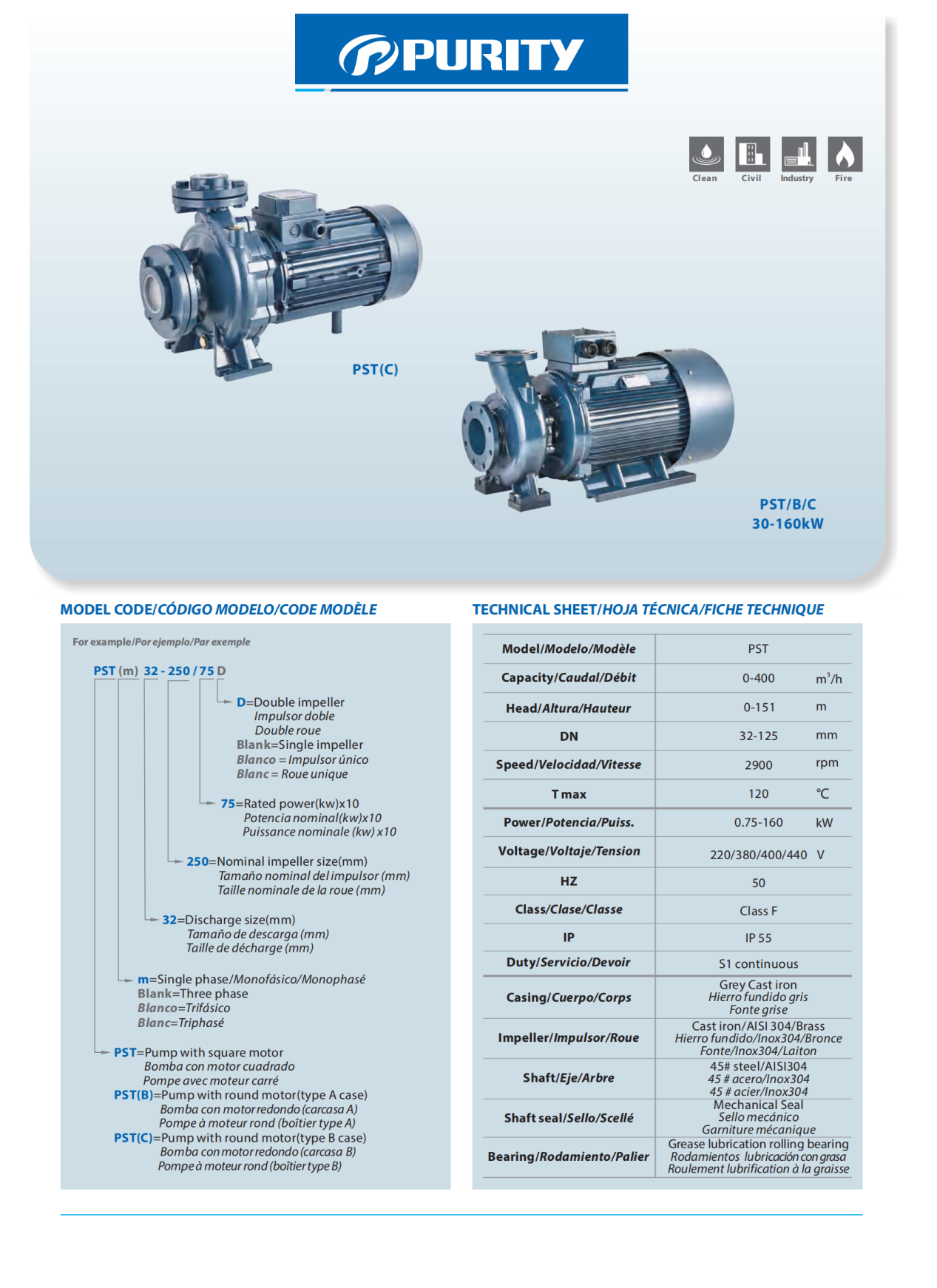

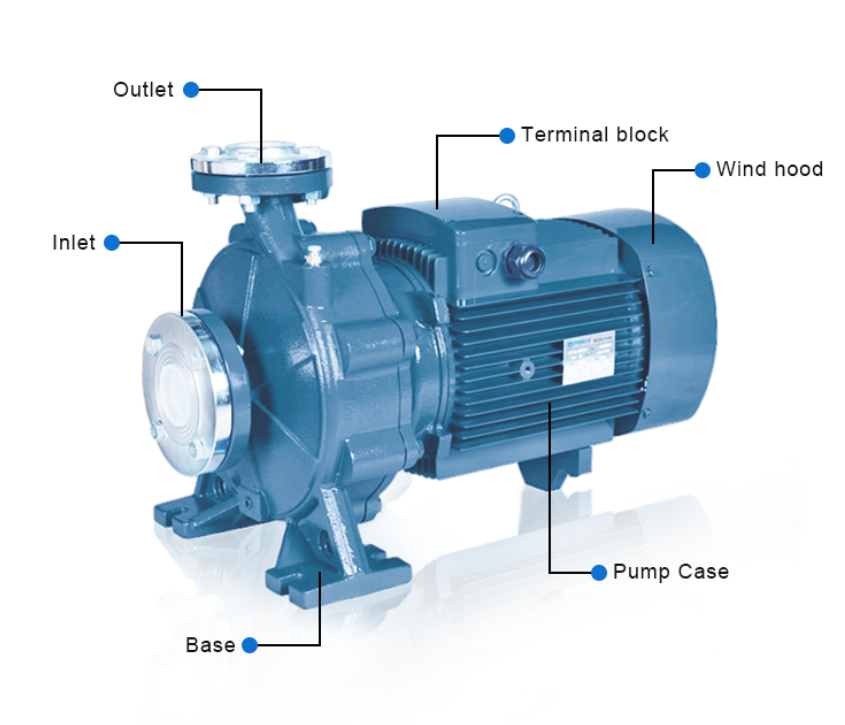

Product Description

Product Description

TECHNICAL DESCRIPTION

New EN733 standard centrifugal pump

Original design by PURITY (patented)

Both square motor & round motor available

YE3 high efficient motor, with protection IP55 class F

Pump case with anti-corrosive coating

Impeller in stainless steel AISI 304 or cast iron

Shaft in stainless steel AISI 304 or galvanized iron

Galvanized counter flange with bolts, nuts and gaskets

Quality NSK bearing, wear resistance mechanical seal

APPLICATIONS

Suitable for use with clean water and liquids that are not chemically

aggressive towards the materials from which the pump is made.

The EN733 centrifugal pumps are recommended for use in water supply,

cleaning sets, pressure boosting, firefighting sets, irrigation, industrial

applications, water circulation in climatisation sets, agricultural.

USING LIMITS

Liquid temperature between -10℃ and +120℃

Ambient temperature up to +50℃

Max. working pressure 16 bar

Continuous service S1

PATENTS

Registered model PST

Registered Patent Design n° 201530478502.0

STANDARD IMPELLER MATERIAL

|

DISCHAEGE SIZE |

IMPELLER SIZE |

||||||

|

125 |

160 |

200 |

250 |

250D |

315 |

400 |

|

|

32 |

SS304 |

SS304 |

SS304 |

Cast iron |

SS304 |

||

|

40 |

Cast iron |

Cast iron |

Cast iron |

Cast iron |

/ |

||

|

50 |

Cast iron |

Cast iron |

Cast iron |

Cast iron |

/ |

||

|

65 |

Cast iron |

Cast iron |

Cast iron |

Cast iron |

/ |

Cast iron |

|

|

80 |

Cast iron |

Cast iron |

Cast iron |

Cast iron |

/ |

Cast iron |

Cast iron |

|

100 |

Cast iron |

Cast iron |

Cast iron |

/ |

Cast iron |

Cast iron |

|

|

125 |

Cast iron |

Cast iron |

/ |

Cast iron |

Cast iron |

||

|

150 |

Cast iron |

Cast iron |

/ |

Cast iron |

Cast iron |

||

|

200 |

Cast iron |

/ |

Cast iron |

Cast iron |

|||

|

250 |

/ |

Cast iron |

Cast iron |

||||

| TECHICAL DATA/DATOS TECNICOS | 60 HZ n=3500 1/min |

|

MODEL MODELO |

Power |

us |

Q=DELIVERY / CAUDAL |

DN |

|||||||||||||||||||

|

0 |

26 |

40 |

66 |

79 |

106 |

119 |

159 |

185 |

211 |

238 |

317 |

370 |

396 |

476 |

529 |

608 |

793 |

925 |

|||||

|

l/min |

0 |

100 |

150 |

250 |

300 |

400 |

450 |

600 |

700 |

800 |

900 |

1200 |

1400 |

1500 |

1800 |

2000 |

2300 |

3000 |

3500 |

||||

|

kw |

hp |

m³/h |

0 |

6 |

9 |

15 |

18 |

24 |

27 |

36 |

42 |

48 |

54 |

72 |

84 |

90 |

108 |

120 |

138 |

180 |

210 |

mm |

|

|

32-125/07 |

0.75 |

1 |

Head |

17.5 |

16.7 |

15 |

12 |

9 |

50x32 |

||||||||||||||

|

32-125/11 |

1.1 |

1.5 |

22 |

21 |

19.7 |

16.5 |

14.5 |

9 |

50x32 |

||||||||||||||

|

32-160/15 |

1.5 |

2 |

25.4 |

23.7 |

22.5 |

18.5 |

15.8 |

50x32 |

|||||||||||||||

|

32-160/22 |

2.2 |

3 |

31 |

29.6 |

28.5 |

24.5 |

22 |

15 |

50x32 |

||||||||||||||

|

32-160/30 |

3 |

4 |

35 |

34.3 |

34 |

28 |

25.5 |

19 |

15 |

50x32 |

|||||||||||||

|

32-200/30 |

3 |

4 |

44.2 |

43 |

39.8 |

35.2 |

32.2 |

24.6 |

19.8 |

50x32 |

|||||||||||||

|

32-200/40 |

4 |

5.5 |

54.5 |

52 |

50 |

45.5 |

41.9 |

35 |

30.3 |

50x32 |

|||||||||||||

|

32-250/55 |

5.5 |

7.5 |

60 |

59.5 |

59 |

55 |

53 |

49 |

46 |

50x32 |

|||||||||||||

|

32-250/75 |

7.5 |

10 |

75 |

74.5 |

74.3 |

73.5 |

72.5 |

68.5 |

67.3 |

60 |

50x32 |

||||||||||||

|

32-250/110 |

11 |

15 |

90 |

87.5 |

85.8 |

82 |

79 |

75 |

72 |

65 |

50x32 |

||||||||||||

|

32-250/55D |

5.5 |

7.5 |

79.5 |

77 |

74 |

70 |

66 |

54 |

42 |

50x32 |

|||||||||||||

|

32-250/75D |

7.5 |

10 |

95 |

93 |

91 |

87 |

83 |

75 |

70 |

32 |

50x32 |

||||||||||||

|

40-125/11 |

1.1 |

1.5 |

14.7 |

13.5 |

11.5 |

10.1 |

5.8 |

65x40 |

|||||||||||||||

|

40-125/15 |

1.5 |

2 |

18.1 |

17 |

15 |

13.9 |

9.6 |

6 |

65x40 |

||||||||||||||

|

40-125/22 |

2.2 |

3 |

24.5 |

23.2 |

21.5 |

20.2 |

16 |

13 |

8.3 |

65x40 |

|||||||||||||

|

40-160/30 |

3 |

4 |

31.8 |

29.5 |

27.5 |

26.3 |

21.5 |

17.5 |

65x40 |

||||||||||||||

|

40-160/40 |

4 |

5.5 |

38 |

36 |

34 |

33 |

28.5 |

25 |

20.1 |

65x40 |

|||||||||||||

|

40-200/55 |

5.5 |

7.5 |

46 |

43.8 |

41.3 |

40.1 |

35 |

30 |

65x40 |

||||||||||||||

|

40-200/75 |

7.5 |

10 |

57 |

53.6 |

51.5 |

50 |

45 |

41 |

36.5 |

65x40 |

|||||||||||||

|

40-250/92 |

9.2 |

12.5 |

64 |

59 |

56.5 |

55 |

49.5 |

45 |

39.8 |

65x40 |

|||||||||||||

|

40-250/110 |

11 |

15 |

78 |

75 |

73 |

72 |

67 |

63 |

56 |

43 |

65x40 |

||||||||||||

|

40-250/150 |

15 |

20 |

88.5 |

83.5 |

80.5 |

79 |

74 |

70.5 |

65 |

52 |

65x40 |

||||||||||||

|

50-125/22 |

2.2 |

3 |

17 |

15.4 |

14 |

12.8 |

11.5 |

6.5 |

65x50 |

||||||||||||||

|

50-125/30 |

3 |

4 |

20 |

18.8 |

18 |

17 |

15.6 |

11 |

65x50 |

||||||||||||||

|

50-125/40 |

4 |

5.5 |

24 |

23.1 |

23 |

21.5 |

20.3 |

15.8 |

11.8 |

65x50 |

|||||||||||||

|

50-160/55 |

5.5 |

7.5 |

32 |

30.6 |

30 |

28 |

26.6 |

20.5 |

14.8 |

65x50 |

|||||||||||||

|

50-160/75 |

7.5 |

10 |

40 |

38 |

37 |

36 |

34.4 |

29 |

24 |

21 |

65x50 |

||||||||||||

|

50-200/92 |

9.2 |

12.5 |

50.5 |

46.8 |

45 |

43 |

40.9 |

32.5 |

26.7 |

65x50 |

|||||||||||||

|

50-200/110 |

11 |

15 |

57.5 |

53.5 |

52 |

50 |

47.5 |

40 |

34 |

29 |

65x50 |

||||||||||||

|

50-200/150 |

15 |

20 |

62 |

58 |

56.5 |

54.5 |

52 |

44.5 |

39 |

35.5 |

65x50 |

||||||||||||

|

50-250/150 |

15 |

20 |

68.5 |

64 |

63 |

61.5 |

59 |

50 |

41 |

65x50 |

|||||||||||||

|

50-250/185 |

18.5 |

25 |

79 |

75.8 |

74.8 |

74 |

71.5 |

63.5 |

55.5 |

47 |

65x50 |

||||||||||||

|

50-250/220 |

22 |

30 |

89.5 |

86 |

85.3 |

84 |

81.5 |

73.5 |

65.5 |

57 |

65x50 |

||||||||||||

|

65-125/40 |

4 |

5.5 |

19 |

17.3 |

16.8 |

14.5 |

13 |

11.8 |

80x65 |

||||||||||||||

|

65-125/55 |

5.5 |

7.5 |

23 |

21.3 |

20.9 |

19 |

17.5 |

16.7 |

13.7 |

80x65 |

|||||||||||||

|

65-125/75 |

7.5 |

10 |

27 |

26 |

25.6 |

24.5 |

23 |

22.5 |

20 |

18 |

80x65 |

||||||||||||

|

65-160/92 |

9.2 |

12.5 |

33 |

31.5 |

30 |

28 |

27.1 |

24 |

21.5 |

80x65 |

|||||||||||||

|

65-160/110 |

11 |

15 |

36 |

34.5 |

33 |

31.5 |

30.8 |

28 |

25.5 |

80x65 |

|||||||||||||

|

65-160/150 |

15 |

20 |

42 |

41 |

40 |

38.5 |

37.8 |

35 |

33 |

29.5 |

80x65 |

||||||||||||

|

65-200/150 |

15 |

20 |

45 |

45.5 |

43 |

41 |

40.2 |

36.5 |

34 |

80x65 |

|||||||||||||

|

65-200/185 |

18.5 |

25 |

52 |

52.3 |

51 |

49 |

48.2 |

44.5 |

42 |

80x65 |

|||||||||||||

|

65-200/220 |

22 |

30 |

59 |

59.5 |

58 |

56 |

55 |

52 |

49.5 |

44.5 |

80x65 |

||||||||||||

|

65-250/220 |

22 |

30 |

64.8 |

64.7 |

62 |

60 |

58.5 |

53 |

50 |

80x65 |

|||||||||||||

|

65-250/300 |

30 |

40 |

80 |

79.8 |

77.5 |

75.5 |

74.5 |

70 |

66 |

58 |

80x65 |

||||||||||||

|

65-250/370 |

37 |

50 |

92 |

90.5 |

88.5 |

87 |

85 |

80.5 |

78 |

68 |

80x65 |

||||||||||||

|

80-125/40 |

4 |

5.5 |

17 |

16.5 |

15.9 |

14.3 |

13.5 |

11.6 |

10 |

7.5 |

100x80 |

||||||||||||

|

80-125/55 |

5.5 |

7.5 |

21 |

20.5 |

20 |

19 |

18 |

16.5 |

15 |

12.5 |

9.5 |

100x80 |

|||||||||||

|

80-125/75 |

7.5 |

10 |

26 |

25 |

25 |

24.5 |

23.8 |

22.5 |

21.5 |

19.5 |

16.5 |

100x80 |

|||||||||||

| TECHICAL DATA/DATOS TECNICOS | 60 HZ n=3500 1/min |

|

MODEL MODELO |

Power |

us |

Q=DELIVERY / CAUDAL |

DN |

||||||||||||||||||

|

0 |

264 |

396 |

529 |

634 |

793 |

881 |

925 |

969 |

1057 |

1233 |

1322 |

1586 |

1762 |

2203 |

2643 |

3524 |

4405 |

|||||

|

l/min |

0 |

1000 |

1500 |

2000 |

2400 |

3000 |

3333 |

3500 |

3666 |

4000 |

4666 |

5000 |

6000 |

6666 |

8333 |

10000 |

13333 |

16666 |

||||

|

kw |

hp |

m³/h |

0 |

60 |

90 |

120 |

144 |

180 |

200 |

210 |

220 |

240 |

280 |

300 |

360 |

400 |

500 |

600 |

800 |

1000 |

mm |

|

|

80-160/110 |

11 |

15 |

Head H(m) |

27 |

27 |

27.3 |

24.5 |

21.1 |

16 |

100x80 |

||||||||||||

|

80-160/150 |

15 |

20 |

32.8 |

32.6 |

32.5 |

30.2 |

27 |

22.1 |

18.5 |

16.7 |

100x80 |

|||||||||||

|

80-160/185 |

18.5 |

25 |

39 |

38.5 |

38 |

36.7 |

33.6 |

28.8 |

25.3 |

23.5 |

100x80 |

|||||||||||

|

80-160/220 |

22 |

30 |

44 |

43.5 |

43 |

41.7 |

38.6 |

33.8 |

30.3 |

28.5 |

100x80 |

|||||||||||

|

80-200/220 |

22 |

30 |

48 |

47.7 |

47.5 |

43.5 |

39.2 |

32.5 |

27.2 |

24.5 |

100x80 |

|||||||||||

|

80-200/300 |

30 |

40 |

60 |

59.7 |

59.5 |

57 |

53.1 |

47 |

42.7 |

40.5 |

100x80 |

|||||||||||

|

80-250/370 |

37 |

50 |

71.5 |

70.9 |

70.5 |

65.5 |

59.3 |

51 |

43.2 |

38.5 |

100x80 |

|||||||||||

|

80-250/450 |

45 |

60 |

88 |

86.7 |

86 |

83.6 |

78.5 |

70.5 |

60 |

51 |

100x80 |

|||||||||||

|

80-250/550 |

55 |

75 |

94.5 |

94.5 |

94.5 |

91.8 |

87 |

79.5 |

72.1 |

68.3 |

100x80 |

|||||||||||

|

100-160/150 |

15 |

20 |

35 |

33.5 |

32.5 |

30 |

27.8 |

24.5 |

21.5 |

20 |

18.3 |

15 |

125x100 |

|||||||||

|

100-160/185 |

18.5 |

25 |

38.5 |

37.5 |

36.5 |

34.3 |

32.2 |

29 |

25.7 |

24 |

22 |

18 |

125x100 |

|||||||||

|

100-160/220 |

22 |

30 |

43 |

41 |

40 |

37.6 |

35.2 |

31.5 |

28.5 |

27 |

25.3 |

22 |

125x100 |

|||||||||

|

100-200/220 |

22 |

30 |

38.5 |

36.7 |

35.7 |

33.8 |

31.7 |

28.5 |

26.8 |

26 |

25 |

22.9 |

16.3 |

13 |

125x100 |

|||||||

|

100-200/300 |

30 |

40 |

44.5 |

42.5 |

42 |

40.2 |

38.8 |

36.7 |

34.2 |

33 |

31.7 |

29 |

21.7 |

18 |

125x100 |

|||||||

|

100-200/370 |

37 |

50 |

55 |

53 |

51 |

50.6 |

49.2 |

47 |

45 |

44 |

42.8 |

40.5 |

32.8 |

29 |

125x100 |

|||||||

|

100-250/450 |

45 |

60 |

65 |

65 |

64 |

63 |

61 |

58 |

56 |

55 |

53.3 |

50 |

39 |

33.5 |

125x100 |

|||||||

|

100-250/550 |

55 |

75 |

77 |

76 |

75.5 |

75 |

73.8 |

72 |

71.7 |

71.5 |

70.7 |

69 |

62.3 |

59 |

125x100 |

|||||||

|

100-250/750 |

75 |

100 |

91 |

91 |

90.5 |

89.7 |

88 |

85.5 |

84 |

83.3 |

81.5 |

78 |

71.7 |

68.5 |

48 |

125x100 |

||||||

|

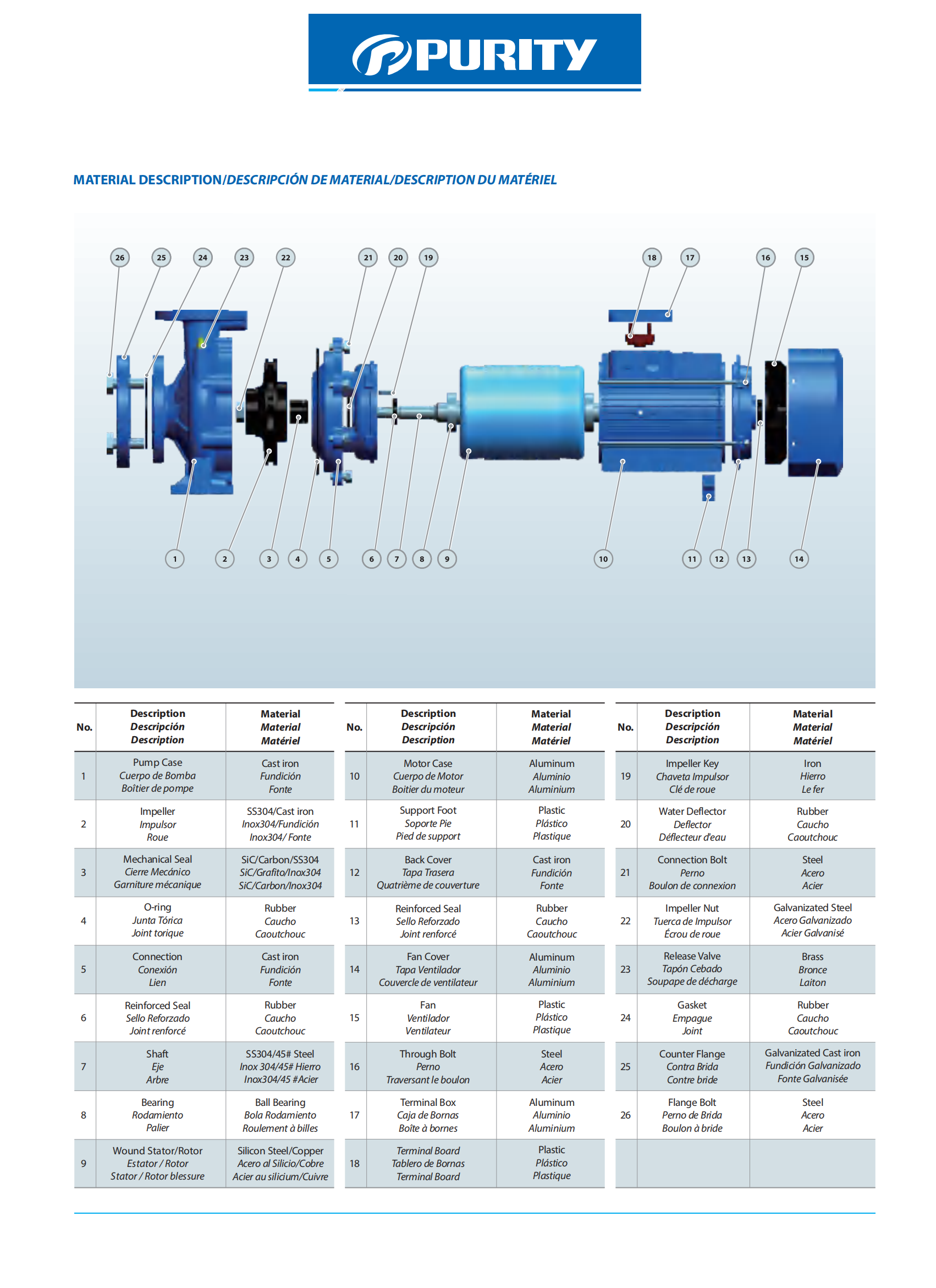

No. |

Description |

Material |

No. |

Description |

Material |

No. |

Description |

Material |

|

1 |

Pump Case |

Cast iron |

10 |

Motor Case |

Aluminum |

19 |

Impeller Key |

Iron |

|

2 |

Impeller |

SS304/Cast iron |

11 |

Support Foot |

Plastic |

20 |

Water Deflector |

Rubber |

|

3 |

Mechanical Seal |

SiC/Carbon/SS304 |

12 |

Back Cover |

Cast iron |

21 |

Connection Bolt |

Steel |

|

4 |

O-ring |

Rubber |

13 |

Reinforced Seal |

Rubber |

22 |

Impeller Nut |

Galvanizated Steel |

|

5 |

Connection |

Cast iron |

14 |

Fan Cover |

Aluminum |

23 |

Release Valve |

Brass |

|

6 |

Reinforced Seal |

Rubber |

15 |

Fan |

Plastic |

24 |

Gasket |

Rubber |

|

7 |

Shaft |

SS304/45# Steel |

16 |

Through Bolt |

Steel |

25 |

Counter Flange |

Galvanizated Cast iron |

|

8 |

Bearing |

Ball Bearing |

17 |

Terminal Box |

Aluminum |

26 |

Flange Bolt |

Steel |

|

9 |

Wound Stator/Rotor |

Silicon Steel/Copper |

18 |

Terminal Board |

Plastic |

|

|

|

|

No. |

Descripción |

Material |

No. |

Descripción |

Material |

No. |

Descripción |

Material |

|

1 |

Cuerpo de Bomba |

Fundición |

10 |

Cuerpo de Motor |

Aluminio |

19 |

Chaveta Impulsor |

Hierro |

|

2 |

Impulsor |

Inox 304/Fundición |

11 |

Soporte Pie |

Plástico |

20 |

Deflector |

Caucho |

|

3 |

Cierre Mecánico |

SiC-Grafito-Inox304 |

12 |

Tapa Trasera |

Fundición |

21 |

Perno |

Acero |

|

4 |

Junta Tórica |

Caucho |

13 |

Sello Reforzado |

Caucho |

22 |

Tuerca de Impulsor |

Acero Galvanizado |

|

5 |

Conexión |

Fundición |

14 |

Tapa Ventilador |

Aluminio |

23 |

Tapón Cebado |

Bronce |

|

6 |

Sello Reforzado |

Caucho |

15 |

Ventilador |

Plástico |

24 |

Empague |

Caucho |

|

7 |

Eje |

Inox 304/45# Hierro |

16 |

Perno |

Acero |

25 |

Contra Brida |

Fundición Galvanizado |

|

8 |

Rodamiento |

Bola Rodamiento |

17 |

Caja de Bornas |

Aluminio |

26 |

Perno de Brida |

Acero |

|

9 |

Estator / Rotor |

Acero al Silicio/Cobre |

18 |

Tablero de Bornas |

Plástico |

|

|

|

Production Line

Packaging & Shipping

Applications

Our Exhibition

Certifications